Hot Rolled Black Mild Carbon MS Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

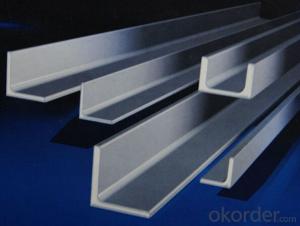

Hot Rolled Black Mild Carbon MS Steel Angle Bar

Detailed Information

Name | Equal/Unequal Angle Steel Bar |

Shape | Equal/Unequal Angle |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

| 75*75 90 degree equal steel angle bar, angle iron steel |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37,etc |

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Equal Angle | 1)Type: 2#-20# |

2)Size: 20mm-200mm | |

3)Thickness: 3.0mm-18mm | |

Unequal Angle | 1)Type: 2.5/1.6-20/12.5 |

2)Long Side: 25-200mm | |

3)Short Side: 16-125mm | |

4)Thickness: 4.0-18mm | |

Length | 5.8m-12.0m or as your requirement |

Surface | Perforated/galvanized/black |

Inspection | BV,SGS,MTC,etc. |

Technique | Hot rolled |

Company Introduction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in medical applications?

- Indeed, medical applications can utilize special steel. Known as stainless steel, special steel is extensively employed in the medical field due to its distinctive qualities and benefits. Its resistance to corrosion is exceptionally high, a crucial aspect in medical settings where exposure to bodily fluids and sterilization procedures is prevalent. Moreover, special steel is biocompatible, meaning it does not trigger adverse reactions upon contact with human tissues or fluids. Consequently, it finds suitability in numerous applications, including surgical instruments, orthopedic implants, dental equipment, and medical devices. The adaptability of special steel allows it to be molded into various forms, ensuring its utilization for diverse medical purposes. Furthermore, its strength and durability contribute significantly to its effectiveness in medical applications, providing dependable and long-lasting tools and equipment. Additionally, special steel can endure high temperatures, making it appropriate for autoclaving and other sterilization methods. In conclusion, the properties of special steel make it an exceptionally fitting material for medical applications, guaranteeing the safety, efficacy, and endurance of medical equipment and devices.

- Q: What are the different types of wear-resistant steel?

- There are several different types of wear-resistant steel, including AR400, AR500, HARDOX, and DOMEX. These types of steel are specifically designed to withstand abrasive wear and impact, making them ideal for applications such as mining equipment, excavator buckets, and conveyor systems. They have high hardness and toughness properties, which help to prolong the lifespan of the equipment and reduce maintenance costs.

- Q: Can special steel be used for making power generation equipment?

- Yes, special steel can be used for making power generation equipment. Special steel is known for its high strength, durability, and resistance to corrosion, making it an ideal choice for manufacturing components such as turbines, generators, and boilers that are used in power generation processes.

- Q: How is maraging steel used in the production of aerospace components?

- Maraging steel is extensively used in the production of aerospace components due to its exceptional strength, toughness, and resistance to wear and fatigue. Its unique properties, achieved through a special aging process, make it ideal for critical components such as landing gear, engine shafts, and missile casings. The high strength-to-weight ratio of maraging steel allows for lighter, more fuel-efficient aircraft, while its durability ensures long-lasting performance in demanding aerospace environments.

- Q: What are some examples of special steel alloys?

- Some examples of special steel alloys include stainless steel, tool steel, high-speed steel, alloy steel, and maraging steel.

- Q: How is alloy steel used in the manufacturing of gears and shafts?

- Alloy steel is commonly used in the manufacturing of gears and shafts due to its superior strength, durability, and resistance to wear and tear. This type of steel is created by combining iron with other elements, such as manganese, nickel, chromium, or molybdenum, to enhance its mechanical properties. The alloying elements increase the hardness, toughness, and heat resistance of the steel, making it ideal for handling the high stresses and loads experienced by gears and shafts in various machinery and automotive applications. Additionally, alloy steel can be heat-treated to further improve its strength and wear resistance, ensuring the longevity and reliability of gears and shafts in demanding operating conditions.

- Q: What are the specific requirements for special steel used in the nuclear industry?

- Special steel used in the nuclear industry must meet specific requirements to ensure safety, durability, and reliability. These requirements include: 1. Radiation Resistance: Special steel used in the nuclear industry must possess high radiation resistance to withstand the intense radiation levels present in nuclear reactors. This means that the steel should have low neutron absorption and minimal degradation under irradiation. 2. High Strength and Toughness: Nuclear reactors operate under extreme conditions, including high temperatures and pressure. Special steel used in the nuclear industry must have excellent strength and toughness to withstand these conditions and prevent structural failure. 3. Corrosion Resistance: The steel used in nuclear applications must be highly resistant to corrosion, as exposure to corrosive environments can compromise the integrity of the reactor components. This involves the steel having low susceptibility to stress corrosion cracking, intergranular corrosion, and pitting corrosion. 4. Low Impurity Content: Special steel used in the nuclear industry must have a low impurity content to minimize the potential for radioactive contamination. Any impurities present in the steel can become activated and release radioactive particles, posing a significant safety hazard. 5. Thermal Stability: The steel must have excellent thermal stability to maintain its mechanical properties even under high-temperature conditions. This ensures that the steel remains reliable and performs as expected during prolonged exposure to elevated temperatures. 6. Non-Magnetic Properties: Some components in nuclear reactors require non-magnetic materials to prevent interference with sensitive instruments and equipment. Special steel used in these applications must possess non-magnetic properties to meet this requirement. 7. Regulatory Compliance: Special steel used in the nuclear industry must meet specific regulatory standards and certifications to ensure its suitability for use in nuclear facilities. These standards may vary depending on the country or region, but they typically encompass rigorous quality control, testing, and inspection procedures. Meeting these specific requirements for special steel used in the nuclear industry is crucial for maintaining the safety and integrity of nuclear reactors. Compliance with these standards ensures that the steel can withstand the harsh conditions and the potential hazards associated with nuclear power generation.

- Q: Can special steel be used in the pharmaceutical manufacturing industry?

- Yes, special steel can be used in the pharmaceutical manufacturing industry. Special steel is often chosen for its high corrosion resistance, hygiene, and cleanability properties. It is commonly used in the production of pharmaceutical equipment such as tanks, vessels, valves, and piping systems to ensure the quality and safety of pharmaceutical products.

- Q: What are the future trends and innovations expected in special steel production?

- In the future, we can expect several trends and innovations in special steel production. One of the key trends is the development of advanced alloys with improved strength, corrosion resistance, and heat resistance properties. These alloys will be tailored to meet the specific requirements of industries such as automotive, aerospace, and energy. Another trend is the adoption of advanced manufacturing techniques, including additive manufacturing or 3D printing. This technology enables the production of complex geometries and customized components, leading to increased efficiency and reduced material waste. Furthermore, the integration of digital technologies and data analytics will play a significant role in optimizing production processes and improving quality control. Predictive maintenance systems, real-time monitoring, and artificial intelligence-based algorithms will enhance productivity and reduce downtime. Sustainability and environmental concerns will also shape the future of special steel production. There will be a focus on developing greener processes, such as using renewable energy sources and reducing carbon emissions. Additionally, the recycling and reusing of steel will be emphasized to minimize waste and conserve resources. Overall, the future of special steel production will be marked by advanced alloys, additive manufacturing, digitalization, sustainability, and a continued commitment to meeting the evolving needs of various industries.

- Q: What are the requirements for special steel used in chemical processing?

- The requirements for special steel used in chemical processing are generally more stringent compared to regular steel due to the harsh and corrosive nature of the chemicals involved. Some of the key requirements for special steel in chemical processing include: 1. Corrosion resistance: Special steel used in chemical processing must exhibit high resistance to corrosion from acids, alkalis, and other corrosive chemicals. This is achieved by adding alloying elements such as chromium, nickel, and molybdenum, which form a protective oxide layer on the surface of the steel, preventing it from reacting with the chemicals. 2. High temperature resistance: Chemical processing often involves high-temperature reactions. Therefore, special steel used in this industry must have excellent heat resistance to maintain its strength and structural integrity at elevated temperatures. This is achieved by adding elements like chromium, nickel, and tungsten, which help in maintaining the stability of the steel at high temperatures. 3. Mechanical strength: Special steel used in chemical processing should possess sufficient mechanical strength to withstand the pressures and loads encountered in the process equipment. This requirement is met by adding alloying elements such as manganese, silicon, and carbon, which enhance the steel's strength and toughness. 4. Weldability: Weldability is a crucial requirement for special steel used in chemical processing as it allows for easy fabrication and installation of process equipment. Special steel with good weldability ensures strong and reliable joints, which are essential for the safe and efficient operation of chemical plants. 5. Resistance to stress corrosion cracking: Stress corrosion cracking is a significant concern in chemical processing environments. Therefore, special steel used in this industry should have good resistance to stress corrosion cracking, which is achieved by carefully selecting the alloying elements and controlling the material's microstructure. 6. Cleanliness: Special steel used in chemical processing should be free from impurities and have a low content of harmful elements that could contaminate the process or react with the chemicals. This necessitates strict quality control measures during steel production to ensure the desired cleanliness and purity. Meeting these requirements ensures that special steel used in chemical processing can withstand the aggressive chemical environment, high temperatures, and mechanical stresses encountered in the industry, leading to safe and reliable operation of the process equipment.

Send your message to us

Hot Rolled Black Mild Carbon MS Steel Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords