MS Hot Rolled Low Carbon Alloy Steel Flat bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

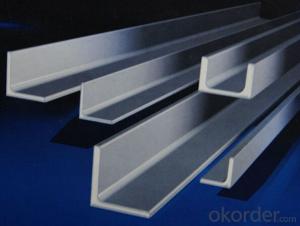

Product Description:

OKorder is offering MS Hot Rolled Low Carbon Alloy Steel Flat bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

MS Hot Rolled Low Carbon Alloy Steel Flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's MS Hot Rolled Low Carbon Alloy Steel Flat bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled and slited

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Q4: How many tons of steel products could be loaded in containers?

A4: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel flat bars be used for DIY projects?

- Yes, steel flat bars can be used for DIY projects. They are versatile and can be easily cut, shaped, and welded to fit various project needs. Whether it's for creating shelves, furniture, brackets, or structural supports, steel flat bars offer strength, durability, and a sleek modern look.

- Q: What are the different tolerance levels for steel flat bars?

- The tolerance levels for steel flat bars can vary depending on the specific requirements and standards set by the industry. Generally, the tolerance levels for steel flat bars can range from tight tolerances, where the dimensions must be extremely precise, to standard tolerances, where a small degree of variation is acceptable. It is important to consult the relevant standards or specifications to determine the exact tolerance levels for a particular application.

- Q: How do steel flat bars perform in terms of water resistance?

- Steel flat bars are generally not very water resistant. Steel is prone to rusting when exposed to moisture or water. If the steel flat bars are not properly treated or protected, they can easily corrode and degrade when in contact with water. However, if the steel flat bars are coated with a protective layer such as paint or galvanized coating, their water resistance can be significantly improved. These coatings act as a barrier, preventing water from directly coming into contact with the steel surface and reducing the risk of rusting. Additionally, regular maintenance and proper storage of steel flat bars can help prolong their lifespan and enhance their water resistance.

- Q: Can steel flat bars be used for making support beams or columns?

- Steel flat bars have the capability to be utilized in the creation of support beams and columns. These versatile construction materials are commonly employed in various structural applications, such as support beams and columns. They possess outstanding strength and durability properties, which render them suitable for bearing heavy loads and providing structural stability. The fabrication and welding of steel flat bars can be easily done to achieve the desired shape and dimensions required for support beams and columns. Moreover, their uniformity and consistent dimensions make them an ideal choice for ensuring structural integrity in construction projects. All in all, steel flat bars offer a reliable and extensively used option for manufacturing support beams and columns due to their strength, durability, and ease of fabrication.

- Q: What is the maximum thickness-to-width ratio for a steel flat bar?

- Several factors, including the specific steel grade, intended usage, and industry standards, influence the maximum thickness-to-width ratio for a steel flat bar. Generally, the maximum ratio is typically 1:10, meaning that the thickness of the flat bar should not surpass 10 times its width. If this ratio is surpassed, it can result in potential problems such as compromised structural integrity, heightened susceptibility to bending or warping, and challenges in fabrication or handling. Therefore, it is crucial to consider the specific application and refer to relevant industry guidelines or standards to determine the appropriate thickness-to-width ratio for a steel flat bar in a given scenario.

- Q: Can steel flat bars be used for manufacturing handrails or balustrades?

- Yes, steel flat bars can be used for manufacturing handrails or balustrades. They are commonly used due to their strength, durability, and versatility in design.

- Q: How do steel flat bars perform in terms of thermal conductivity?

- Compared to other materials, steel flat bars exhibit a relatively high thermal conductivity. As a result, they demonstrate remarkable efficiency in conducting heat. Upon exposure to elevated temperatures, steel flat bars promptly absorb and disperse heat within their structure. Conversely, steel flat bars also efficiently dissipate heat, enabling them to rapidly cool down. This characteristic renders steel flat bars suitable for diverse applications that prioritize thermal conductivity. In the construction industry, they are frequently employed in heat transfer systems, heat exchangers, and other thermal management applications.

- Q: What are steel flat bars?

- Steel flat bars are long rectangular pieces of steel that have a flat surface and sharp edges. They are commonly used in construction, manufacturing, and industrial applications. These bars are made from various grades of steel, such as carbon steel or stainless steel, and are produced through a process called hot rolling or cold drawing. Steel flat bars have a wide range of uses due to their versatility and strength. They are often used as structural supports, braces, or framing components in buildings and bridges. In manufacturing, they can be used as base plates for machinery, brackets, or as raw material for fabrication. Additionally, steel flat bars are frequently utilized in the automotive, aerospace, and marine industries. The flat surface of these bars allows for easy welding, cutting, and machining, making them highly adaptable to different projects and applications. They can be shaped, bent, or drilled to fit specific requirements. The sharp edges of steel flat bars also provide stability and structural support when used in construction or as load-bearing components. Steel flat bars come in various sizes, thicknesses, and lengths, allowing for customization and flexibility in their use. They are typically available in standard dimensions and can be purchased from steel suppliers or metal fabrication shops. Overall, steel flat bars are essential building materials that offer strength, durability, and versatility. They are widely used in a range of industries and applications, making them a crucial component in many construction and manufacturing projects.

- Q: Can steel flat bars be drilled or machined?

- Certainly! Drilling or machining steel flat bars is indeed possible. Steel, being a highly adaptable substance, can be easily manipulated through the utilization of suitable tools and techniques. In the case of drilling, the employment of a drill press or a handheld drill equipped with an appropriate drill bit can effectively penetrate steel flat bars. Additionally, achieving desired shapes or dimensions can be achieved through the use of milling machines, lathes, or CNC machines. Nevertheless, it is crucial to exercise caution by utilizing appropriate cutting tools and lubricants to ensure efficient machining and protect the steel flat bars from any potential damage.

- Q: Are steel flat bars commonly used in the construction of sports facilities?

- Yes, steel flat bars are commonly used in the construction of sports facilities. They are often utilized for structural support, such as in the construction of bleachers, fencing, and overhead structures. Steel flat bars provide strength and durability, making them suitable for the demanding needs of sports facilities.

Send your message to us

MS Hot Rolled Low Carbon Alloy Steel Flat bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords