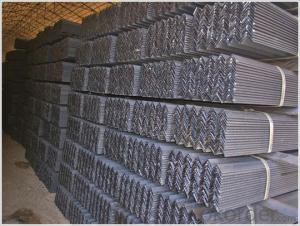

Hot Rolled Steel Angle Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 40*40*3 | 1.852 | 45*45*5 | 3.369 |

| 40*40*4 | 2.422 | 50*50*4 | 3.059 |

| 40*40*5 | 2.976 | 50*50*5 | 3.77 |

| 45*45*4 | 2.736 | 50*50*6 | 4.465 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What is the maximum load capacity of a steel angle?

- The maximum load capacity of a steel angle depends on various factors such as the dimensions, thickness, and quality of the steel angle. It is essential to consult engineering specifications or contact a structural engineer to determine the specific maximum load capacity for a particular steel angle.

- Q: How do steel angles compare to aluminum angles?

- Different applications require different materials, with steel angles and aluminum angles having distinct properties and characteristics. Steel angles, also referred to as steel L-shaped beams, are known for their robustness and resilience. They find extensive use in construction projects like building frames, bridges, and industrial structures where their ability to bear heavy loads is essential. Comparatively, steel angles possess a higher tensile strength than their aluminum counterparts, allowing them to withstand greater forces without deformation or breakage. On the contrary, aluminum angles are lightweight and possess exceptional corrosion resistance. This makes them ideal for applications where weight is a crucial factor, such as the aerospace and marine industries. Additionally, aluminum angles are commonly employed in architectural projects due to their malleability and ability to be shaped into various designs. Furthermore, aluminum angles exhibit commendable thermal and electrical conductivity properties, making them well-suited for heat transfer applications. When it comes to cost, steel angles are generally more budget-friendly due to lower steel production costs. However, aluminum angles often demand less maintenance and boast a longer lifespan, thanks to their resistance against corrosion. Ultimately, the selection between steel angles and aluminum angles is contingent upon the specific requirements of the project. If the priority is high strength and durability, steel angles are the preferred option. Conversely, if weight, corrosion resistance, and design flexibility hold greater importance, aluminum angles are the superior choice.

- Q: What are the different types of connections used for steel angles in steel frames?

- There are several types of connections used for steel angles in steel frames, including welded connections, bolted connections, and riveted connections. Welded connections involve fusing the angles together using heat, creating a strong and permanent bond. Bolted connections involve using bolts and nuts to secure the angles together, allowing for easy disassembly if necessary. Riveted connections involve using rivets, which are metal pins, to hold the angles together by forming a permanent, tight fit. The choice of connection type depends on the specific requirements of the steel frame and the desired level of strength and durability.

- Q: How do you join two steel angles together?

- There are several methods available for joining two steel angles together, depending on the specific application and requirements. Here are a few commonly used techniques: 1. Welding: The most widely used method for joining steel angles is welding. This involves heating the joint to a high temperature and melting a compatible metal filler material to fuse the angles together. Welding creates a strong and permanent bond, but it requires specialized equipment and expertise, so it is usually carried out by trained professionals. 2. Bolting: Another option is to use bolts or screws to connect the steel angles. This involves drilling holes in both angles and securing them with appropriate fasteners. Bolting allows for easier disassembly and modification if necessary, but it may not offer the same level of strength as welding. 3. Riveting: Riveting is a technique that utilizes metal pins or bolts called rivets to hold the steel angles together. It involves drilling holes in the angles and inserting the rivets, which are then hammered or pressed to create a permanent joint. Riveting is commonly employed in structural applications where high strength and load-bearing capacity are essential. 4. Adhesive bonding: In certain cases, adhesive bonding can be used to join steel angles. Specialized adhesives are applied to the joint surfaces, and then the angles are pressed together and left to cure. This method can result in a clean and visually appealing bond, although it may not possess the same strength as other mechanical methods. When choosing a method to join steel angles, it is crucial to consider factors such as load-bearing requirements, structural integrity, accessibility, and the specific conditions of the application. Consulting with a structural engineer or a professional in the field can help determine the most suitable technique for your particular needs.

- Q: Can steel angles be used for conveyor supports?

- Yes, steel angles can be used for conveyor supports as they provide stability and strength due to their structural design.

- Q: What is the typical density of steel angles?

- Steel angles can have varying densities depending on the particular steel type and grade employed. On average, their density falls within the range of 7.7 to 8.1 grams per cubic centimeter (g/cm³), or equivalently 7700 to 8100 kilograms per cubic meter (kg/m³). In comparison to other substances, steel angles possess a notably high density, imparting strength and durability for a multitude of structural and construction purposes.

- Q: Do steel angles require any special maintenance?

- No special maintenance is needed for steel angles, but their lifespan can be prolonged with proper care and attention. It is recommended to regularly clean them to remove dirt, debris, and corrosive substances. Additionally, it is important to promptly address any signs of rust, cracks, or damage to prevent further deterioration. To prevent corrosion and extend the life of the steel angles, applying a protective coating or paint is advisable. In general, steel angles require minimal maintenance, but regular inspections and maintenance practices are crucial for optimal performance and longevity.

- Q: Are steel angles resistant to high winds?

- Steel angles are able to resist high winds. Steel is renowned for its strength and durability, making it an excellent choice for structures requiring the ability to withstand strong winds. Specifically, steel angles offer added stability and support to buildings by distributing the load and resisting bending forces. Consequently, they exhibit a high level of resistance against the powerful forces exerted by high winds. Moreover, steel angles are commonly utilized in the construction of buildings and infrastructure in areas that are susceptible to hurricanes, tornadoes, or other severe weather conditions, further demonstrating their capacity to withstand high winds. In summary, steel angles are a dependable and efficient solution for ensuring structural integrity and wind resistance in diverse applications.

- Q: Can steel angles be used in machine frames?

- Yes, steel angles can be used in machine frames. Steel angles provide structural support and stability, making them suitable for constructing machine frames. They can withstand heavy loads and offer excellent resistance to bending and twisting forces, making them a popular choice in various industrial applications.

- Q: What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches