Mild Carbon Steel Pipe Weld Steel Tube factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Full series of products provides an easier access for one stop purchase

▲ Line pipe

▲ Tubing and casing

▲ L & M & H boiler tube

▲ Gas cylinder tube & pipe

▲ Mechanical & Structural pipe

▲ Ship-building tube & pipe

▲ Automobile tube & pipe

1.Seamless pipe professor

2.MTC,ISO,API certificate

3.ASTM,DIN,BS,JIS,GB

4.On time delivery

5.Big store,excellent package

2、Main Features of the Seamless Pipe ASTM A106/53:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

● Full series of products provides an easier access for one stop purchase

▲ Electric Resistance Welded (ERW) Steel Pipe

▲ Longitudinal Submerged Arc Welded (LSAW) Steel Pipe

▲ Spiral Submerged Arc Welded (SSAW) Steel Pipe

▲ Hollow Section (Square and Rectangle Pipe)

▲ Hot Dipped Galvanized Steel Pipe

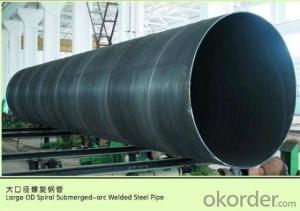

6、Seamless Pipe ASTM A106/53 Images:

- Q: How are steel pipes used in the infrastructure development?

- Steel pipes are widely used in infrastructure development as they provide strength, durability, and versatility for various applications. They are commonly used in the construction of bridges, highways, and buildings as structural elements. Steel pipes are also used in water and sewage systems, as they have excellent corrosion resistance and can withstand high pressure. Additionally, steel pipes are used for transporting oil, gas, and other fluids, making them crucial for the energy industry. Overall, steel pipes play a vital role in the development and maintenance of infrastructure, ensuring its stability and functionality.

- Q: How are steel pipes used in the fabrication of storage tanks?

- Due to their strength, durability, and versatility, steel pipes are widely employed in the construction of storage tanks. Throughout the tank fabrication process, these pipes serve various functions. To begin with, steel pipes are utilized in establishing the tank's foundation. By providing a robust base, they ensure stability and prevent potential structural problems. Moreover, steel pipes are employed in constructing the tank's shell. Through welding, these pipes are joined together to form a cylindrical structure capable of withstanding the pressure and weight of the stored material. Furthermore, steel pipes are crucial for installing inlet and outlet pipes. These pipes enable the controlled flow of materials in and out of the storage tank. Additionally, steel pipes frequently play a role in fabricating support structures within the tank. These structures distribute the weight of the stored material and offer additional reinforcement to the tank. When it comes to maintenance and repair, steel pipes are also essential. They are used to install access points such as manholes or inspection ports, facilitating routine inspections, cleaning, and any necessary repairs. In summary, steel pipes are indispensable in the fabrication of storage tanks, providing a resilient and dependable framework. They are employed in constructing the tank's foundation, shell, inlet and outlet pipes, support structures, and access points. With their durability and versatility, steel pipes ensure the integrity and functionality of storage tanks.

- Q: Will the steel tube dance?

- The steel tube dance tube has a rotating steel tube and a fixed steel tube, so that different types of steel pipe can be chosen according to the type of pipe dance performed by the dancer.

- Q: What is the maximum length of steel pipes available in the market?

- The maximum length of steel pipes available in the market can vary depending on the specific supplier and industry requirements. However, standard lengths typically range from 20 to 40 feet.

- Q: How are steel pipes protected against external mechanical damage?

- Steel pipes are often protected against external mechanical damage through a variety of methods such as applying corrosion-resistant coatings, using protective sleeves or wraps, and implementing casing or encasement systems. These measures help to safeguard the pipes from potential physical harm caused by external factors like impact, abrasion, or heavy loads, thus ensuring their integrity and longevity.

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Hot rolled seamless tubes are divided into ordinary steel tubes, low and medium pressure boiler tubes, high pressure boiler tubes, alloy steel tubes, stainless steel pipes, oil cracking pipes, geological steel pipes and other steel pipes, etc..

- Q: How to make the steel pipe spray paint is not easy to fall off?

- First, clean the surface of the object to be sprayed (pay attention to whether or not to paint off, which is the key):Remove rust stains, oil and so on, when spraying, the nozzle and spray the best distance is 20cm, should be two times forming, first thin spray again, dry, and then spray second times, this is more uniform, and not easy to hang

- Q: How are steel pipes used in the food and beverage industry?

- Steel pipes are commonly used in the food and beverage industry for various applications including transporting water, steam, gases, and other liquids. They are preferred due to their durability, strength, and resistance to corrosion, ensuring the safety and hygiene of food and beverage products. These pipes are used in processes such as conveying ingredients, transferring liquids and gases during production, and supplying utilities like water and steam for cleaning and sterilization purposes.

- Q: What are the common challenges faced during steel pipe installation?

- When installing steel pipes, there are various challenges that may arise. One of these challenges involves the need to ensure that the pipe sections are properly aligned and fit together correctly. Welding or threading is typically used to join steel pipes, and if the alignment is not precise, it can result in leaks or weak points in the pipeline. To overcome this challenge, it is necessary to use careful measurements and alignment techniques to ensure a secure and tight fit between the pipe sections. Another challenge that arises is dealing with corrosion and rust. Steel pipes are prone to corrosion, especially when exposed to moisture or corrosive substances. This can lead to the deterioration of the pipes over time, compromising their structural integrity and increasing the risk of leaks. To address this challenge, it is possible to apply protective coatings or linings to the steel pipes to prevent corrosion and extend their lifespan. Additionally, the weight and size of steel pipes can pose a challenge during installation. Steel pipes are heavy, and it can be physically demanding to maneuver and position them. Moreover, the large diameter of some steel pipes makes it difficult to transport and handle them in tight spaces or through narrow pathways. Overcoming this challenge often requires the use of heavy machinery, such as cranes or forklifts, to lift and position the pipes correctly. Lastly, environmental factors can also present challenges during steel pipe installation. Extreme temperatures, harsh weather conditions, or unstable soil conditions can impact the installation process. For example, freezing temperatures can make it challenging to weld the pipes, while unstable soil may require additional reinforcement or stabilization measures to ensure the longevity of the pipeline. In conclusion, the challenges commonly faced during steel pipe installation include the need for proper alignment, the issue of corrosion and rust, the handling of the weight and size of the pipes, and the consideration of environmental factors. Overcoming these challenges requires careful planning, attention to detail, and the utilization of appropriate techniques and equipment.

- Q: How are steel pipes used in the manufacturing of desalination plants?

- Steel pipes are used in the manufacturing of desalination plants for various purposes such as transporting seawater, brine, and treated water within the plant. They provide durability, corrosion resistance, and the necessary strength to withstand high-pressure conditions, ensuring the efficient operation and long-term reliability of the desalination process.

Send your message to us

Mild Carbon Steel Pipe Weld Steel Tube factory

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords