LSAW SSAW CARBON STEEL PIPE ASTM API 5L PIPE LINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | Normal exporting packing,in container or bulk vessel or as per clients' request |

Delivery Detail: | 2 months after confimed contract |

Specifications

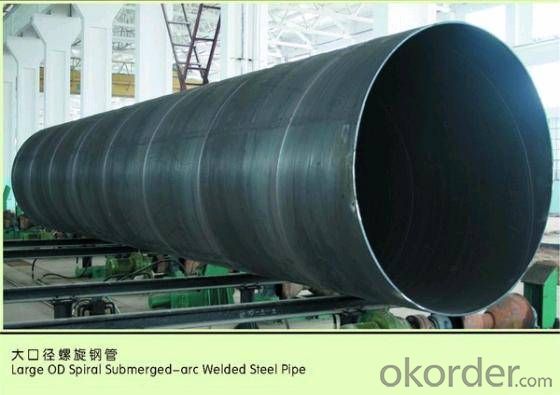

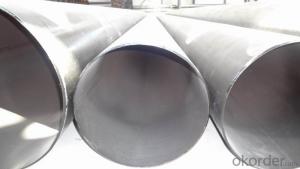

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Grade: X42, X46, X50, X52, X60, B, C

OD: 1.5"-28"

WT: SCH10-SCH160

Large Diameter API 5L X70 PSL2 LSAW Steel Pipe

Specifications:

u Standard: API 5L

u Grade: B, C, X42, X46, X50, X52, X56, X60, X65, X70, X80

u OD: 1.5"-28"

u WT: SCH10-SCH160

u Length: 5-12m

u Ends Finish: plain end, bevel end, grooved end

u Surface Treatment: bare, black varnished, oiled finish, red color, anti-corrosion, 3PE, FBE or epoxy coating

u Technique: hot rolled or cold drawn

u Application: api 5l steel pipe for conveying oil, water, gas

u Invoicing: based on theoretical weight or actual weight

u Payment Terms: L/C at sight, T/T or Western Union

u Trade Terms: FOB, CFR, CIF

u Certification: ABS manufacturing assessment, ABS design assessment, API 5CT, API 5L, DNV manufacturer certificate, ISO9001 quality management system certificate, ISO14001 environment management system certificate, GB/T28001 occupational health and safety management system certificate, A1 class manufacturing license of special equipment certificate, CCS, GL, LR, SGS, TüV, PDE

- Q: Can steel pipes be used for airport construction?

- Yes, steel pipes can be used for airport construction. Steel pipes are commonly used in various construction projects due to their durability, strength, and resistance to corrosion. They are capable of withstanding heavy loads and are often used for underground drainage systems, water supply networks, and structural support in airport construction.

- Q: How do you select the right size of steel pipe for a project?

- To select the right size of steel pipe for a project, it is important to consider factors such as the desired flow rate, pressure requirements, fluid type, and the overall structural design. Consulting relevant design codes and standards, performing calculations based on these parameters, and seeking expert advice can help ensure the appropriate size is chosen to meet the project's specific needs.

- Q: How do steel pipes handle thermal expansion and contraction?

- The unique properties and design of steel pipes enable them to handle thermal expansion and contraction. When exposed to high temperatures, steel pipes expand as the molecules in the material gain energy and become more active. Conversely, when exposed to low temperatures, steel pipes contract as the molecules lose energy and become less active. To accommodate these changes, steel pipes are manufactured with specific features. One such feature is the inclusion of clearance between pipe joints. This clearance allows for expansion and contraction without causing stress or deformation in the pipe. Additionally, expansion joints or flexible connectors are used within the piping system to absorb thermal movements and prevent damage. Moreover, steel pipes are commonly installed with appropriate anchoring and support systems. These systems are designed to allow the pipes to expand and contract within a certain range without exerting excessive stress or strain on the structure or surrounding components. Anchoring and support systems also help maintain the overall stability and integrity of the piping system. In certain cases, thermal insulation materials are applied to steel pipes to minimize temperature changes and mitigate the effects of expansion and contraction. These insulating materials assist in maintaining a consistent temperature within the pipe, thereby reducing the magnitude of thermal movements. Overall, due to their inherent strength and flexibility, steel pipes are well-equipped to handle thermal expansion and contraction. With proper design, installation, and maintenance, steel pipes can effectively accommodate temperature changes without compromising their structural integrity or functionality.

- Q: Can steel pipes be used for both high-pressure and low-pressure systems?

- Yes, steel pipes can be used for both high-pressure and low-pressure systems. Steel pipes are known for their strength and durability, making them suitable for various applications. They are capable of withstanding high pressures without deformation or leakage, while also being reliable for low-pressure systems.

- Q: What are the potential health hazards associated with steel pipe installation?

- Some potential health hazards associated with steel pipe installation include exposure to hazardous chemicals used in the coating or treatment of the pipes, inhalation of dust or fumes generated during cutting or welding, and physical injuries due to accidents or mishandling of heavy equipment. Additionally, improper handling or disposal of waste materials and contaminated water can pose environmental health risks. It is important to follow proper safety protocols, use personal protective equipment, and ensure proper ventilation and waste management to mitigate these hazards.

- Q: How are steel pipes used in the construction of stadiums and arenas?

- Steel pipes are commonly used in the construction of stadiums and arenas for various purposes. They are primarily used for the structural framework, supporting the weight of the building and providing stability. Steel pipes are also used for the installation of HVAC systems, electrical wiring, and plumbing, allowing for efficient distribution of utilities throughout the facility. Additionally, steel pipes are utilized for the construction of handrails, fences, and barriers, ensuring safety and security for spectators.

- Q: How long do steel pipes last?

- There are several factors that can influence the lifespan of steel pipes. These factors include the quality of the steel used, the installation environment, and the maintenance and care provided to the pipes. Steel pipes are generally recognized for their durability and long life. When properly installed and regularly maintained, steel pipes can endure for many decades, sometimes even surpassing 50 years. However, it is important to consider external factors that can greatly impact their lifespan, such as corrosion, exposure to extreme temperatures, and chemical reactions. To ensure the reliability and functionality of steel pipes for an extended period, it is crucial to conduct regular inspections, make timely repairs, and apply protective coatings.

- Q: How are steel pipes used in the manufacturing of machinery?

- Steel pipes are used in the manufacturing of machinery primarily for conveying fluid or gas, providing structural support, and acting as a conduit for electrical wiring. They are commonly used as the framework for various machine components, such as conveyor systems, hydraulic equipment, and pneumatic systems. Steel pipes offer durability, strength, and versatility, making them an essential material in machinery manufacturing.

- Q: How do you measure the thickness of a steel pipe?

- Different methods can be used to measure the thickness of a steel pipe, depending on the required precision and available tools. Here, we present three commonly used approaches: 1. Calipers or Vernier Calipers: These are widely used and straightforward tools for measuring thickness. Place the jaws of the calipers on both sides of the pipe, ensuring they are perpendicular to the surface. Gently close the jaws until they touch the pipe, and then read the measurement on the caliper scale. 2. Ultrasonic Thickness Gauge: This method provides more accurate results and is commonly employed in industrial settings. An ultrasonic thickness gauge emits high-frequency sound waves that penetrate the steel pipe. By measuring the time it takes for the sound waves to bounce back, the gauge calculates the pipe's thickness. Before taking the measurement, ensure that the pipe surface is clean and smooth. 3. Magnetic Thickness Gauge: This method is specifically designed for measuring the thickness of ferrous materials like steel. The gauge incorporates a small magnet that adheres to the pipe surface. By applying a magnetic field, the gauge determines the distance between the magnet and the base plate. This distance corresponds to the thickness of the steel pipe. It is important to consider that each method has its own limitations in terms of accuracy. The choice of measurement technique should be based on the desired precision, availability of tools, and the specific requirements of the application.

- Q: What are the different methods of lining steel pipes?

- There are several methods of lining steel pipes, each with its own advantages and uses. Some common methods include: 1. Cement Mortar Lining: This involves the application of a layer of cement mortar on the inner surface of the steel pipe. Cement mortar provides excellent corrosion resistance and smoothness to the pipe, reducing friction and improving flow rates. It is commonly used in water supply systems and sewage treatment plants. 2. Polyethylene (PE) Lining: PE lining involves the insertion of a polyethylene tube into the steel pipe. The tube is usually heat fused or mechanically connected to the steel pipe, creating a seamless and corrosion-resistant lining. PE lining is commonly used in gas transmission and distribution pipelines. 3. Epoxy Lining: Epoxy lining involves the application of an epoxy resin to the inner surface of the steel pipe. Epoxy coatings provide excellent resistance to corrosion, abrasion, and chemicals, making them suitable for various applications such as oil and gas pipelines, water treatment, and industrial processes. 4. Trenchless Pipe Lining: This method is used to rehabilitate existing steel pipes without the need for excavation. It involves the insertion of a liner or resin-coated fabric into the existing pipe, which is then inflated and cured to form a new lining. Trenchless pipe lining is commonly used for sewer and water main rehabilitation. 5. Polyurethane (PU) Lining: PU lining involves spraying or pouring a polyurethane coating onto the inner surface of the steel pipe. Polyurethane linings provide excellent resistance to abrasion, impact, and chemicals, making them suitable for applications in mining, slurry pipelines, and wastewater treatment. These are just a few of the many methods available for lining steel pipes. The choice of lining method depends on factors such as the intended application, the environment, and the desired level of corrosion resistance and durability.

Send your message to us

LSAW SSAW CARBON STEEL PIPE ASTM API 5L PIPE LINE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords