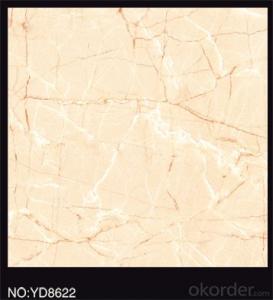

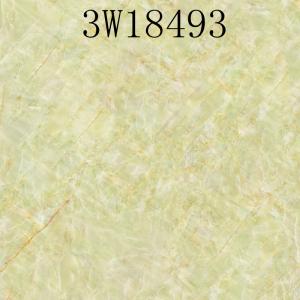

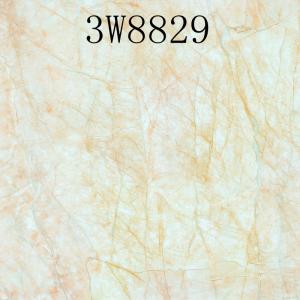

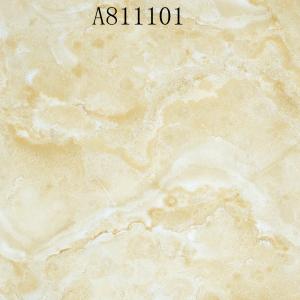

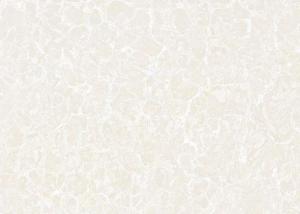

MICRO-CRYATAL POLISHED PORCELAIN TILE 2

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Information :

Tile Type | Micro-Crystal Polished Porcelain Tile |

Certificate | ISO13006, ISO9001 |

Finish | Nano Finish |

Size | 80x80mm |

Other Choices | many designs, colors available |

Features:

1) Available in many designs, specifications and assorted color,unique designs and exclusive quality

2) Used for indoor & outdoor wall and floordecorations, as well as Stair Case Product;

3) Easy to install, anti-dust, washable, acid-proof,alkali-proof, durable

4) Material: glazed porcelain

5) Customized sizes available according to clients’ requirements

6) Available dimensions

Material | Porcelain |

Dimension | 800x800 mm |

Packing | Carton + Wooden Pallets |

Finish | Glossy, over 90 degree. |

Usage | Floor and wall |

The micro crystal polished porcelain tile is widely used for interiorhouse flooring, hotel lobby flooring, wall as well as luxury sites fordecoration.

Vivid stone texture and vein bring our decoration the naturalstone beauty with much lower cost, easier quality control and easier decoration proceeding.

Advanced glass glazing technology to make sure the tile surfacebeauty vivid and clean, via ink-jetting printing.

We could go with OEM model, making 2nd production basedon client’s requirement;

We could offer flexible service on shipment and better supporton payment term;

Our quality guarantee is based on the strict production procedure, quality controlling on the shade, straightness as well as white degree.

Specification and technologyinformation:

· NANO polished

· Water absorption:<0.1%

· Delivery:within 15~20 days after 30%deposit received

- Q: My kitchen has ceramic tile already installed and I despise it and have for years. I do not want to put a big investment into this house as I do not plan on living there for much over 2 more years. I just want to cover it up and make it look better. This site seems pretty legit and only deals with self stick tile. Anyone know of pros or cons? Have any suggestions?

- Cons would be that it costs close to $10 a square foot. I also doubt that it looks as good in person as the site claims. I've installed a lot of surface coverings, including tile-textured vinyl wallpaper and a variety of peel and stick material and they rarely look that convincing when they are right under your nose, as a countertop backsplash would be. That's a lot of money for a coverup job, And you don't say where the tile is installed. Walls? Countertop? Floors? That stickandgo is strictly for walls, not any area that would have moisture lying on it or traffic. If it is just your walls it would be a lot cheaper just to hire someone to tear off the ceramic tile and put up something different. It only cost me $6 a square foot for labor and $3 for material to have a real ceramic subway tile back splash installed in my kitchen last year. It would be even less if you did it yourself. If you are thinking of covering a floor, look at the Trafficmaster Allure material at Home Depot -- excellent product and about $2 a square foot. Installs like a dream, completely waterproof, can go over an uneven surface, adheres to itself, not what is behind it (it floats), easy to remove later, and both the tile and wood versions look and feel absolutely real. We did my friend's large bathroom with it in less than 4 hours last winter and it looks like a hardwood floor and holds up to anything. I used the slate-look tiles in my breakfast room of my previous house and everyone who saw it thought it was real stone. If it's your countertops, it is easy and cheap to replace countertops with new laminate and the new laminates are not your Grandma's formica -- many look like high-end granite and even metals.

- Q: I am going to move into a home that has ugly green and yellowish tile all over the kitchen!! The walls and sink are green, the counters are a wood laminate, the floor is an old beige vinyl, and the cabinets are a dark color and are old and dated. What can i do to make this kitchen much nicer on a really tight budget?! Help!!

- You okorder / and in the search bar (make sure you check site instead of recipe) type in 4 Wall Projects with Glaze it is the 3rd project called Tile Turnaround and gives step by step instructions. Good Luck!

- Q: Hi, I was wondering what type of tile is easier to lay down on a bathroom floor, large, single tiles or small tiles that are connected together by mesh. I have never done anything like this before, so any suggestions would be helpful. Thanks!

- You did not say how big the bathroom was and that is important in deciding what size tile to use... You said layng ceramic tile... you did not say if it was ON the floor or ON the wall behind the vanity top and that makes a difference. I would love to answer as I have just completed another job in my bathroom this week ... but I just do not have enough information from you

- Q: i‘m redoing the floor in a bedroom. i already picked out the ceramic tile i want but i wanted some 4x4 fleur de lis decorative tile to go with it. know where i can find some that‘s reasonably priced?

- i've seen marble, tile and granite warehouses/stores that often have overstock sales. try googleing some in your area.

- Q: are tiles get really dirty fast and i tried everything and i cant get them to stay white could i use bleach?

- Clean your bathroom tiles with a soft cloth or mop using pH neutral cleaning solution. Always wipe off any spills immediately as they happen. Never, ever clean this floor with vinegar, as you will destroy the finish. Tile specific cleaning products are available.I recommend you Lustro Italiano Cleaner and Polish which is specifically designed and PH balanced for tile Surfaces. Compared to other polishes and cleaners, it creates a deeper longer lasting shine. you can find it in my source site.

- Q: I have a couple of tiles that have fell off and need to be put back on, what type glue do you apply to make them stick. They fell off due to foundation problems which is now fixed.

- i would not use a torch. It probably could desire to reason any moisture trapped in the back of the tiles to enhance and then it may reason steam that could desire to pop the tiles off. What i could do is circulate to homestead Depot and purchase Krud Kutter. It softens paint and is quite gentle. Spray on wait slightly and scrub the paint off. As for the caulking there is caulking remover in an analogous area because of the fact the caulk is offered. good luck and effective %.

- Q: I want to know how to make tile based map in java. Retro games used tiled maps (to ease programming and memory management) but those games were created in assembly language. I know basic java. Now I want to make a 2d game in java, starting with a pretty basic 2d platformer type or top-down type. To do this, i need to know the technique required to make a map, a tile map.I have already searched in google and youtube and stack overflow, but none helped much. What I learnt is that I have to make some tile object and make a 2 dimensional matrix to store position of particular tiles. But this does not helped much. Thank you.P.S. there are many programs available on the internet for making tile maps, and also there are game making softwares and also libraries. i do not want to use any of those since i want to make my game with whatever java provides. Thank you. Also forgive my poor english.

- first of all, you need to build different densities of 2D tile arrays according to how much of the map will be in the viewport at any given time. For example, a map at neighborhood level will need a gazillion more tiles than a map at the county level. Then, you need a way of converting the geographic reference at the center of the viewport to the tile that is covered at that zoom level, and for finding the adjacent tiles as well. Then, you'll need to calculate what parts of which tiles you are using will need to be clipped and by how much. Build a canvas using this information. As the map moves, you'll need to add on more adjacent tiles, and discard others, update the clipping, etc.

- Q: Small size tiles for external walls

- 45 * 45mm, 45 * 95mm, 45 * 195mm, 100 * 100mm, 100 * 200mm, 110 * 250mm, 140 * 280mm Tiles, including 100mm * 100mm150mm * 150mm two or so super 200mm should be called tiles 10CM * 10CM, (a lot of specifications) mainly look at what you personally like the specifications.

- Q: How are these tiles differ from each other and how to identify these?

- Porcelain okorder /

- Q: Dont worry about looks with the dollar tile just want to know pricing pretty much on the tile and how expensive it is.

- If you are doing the tile work yourself, it will be cheaper than having one of those fiberglass shower enclosures put in. You are looking at the cost of tile (at $1/sqft.), grout ($10 or less), permabase/durock ($9 per 3x5 sheet), mastic ($30 for high quality), and caulk ($4), to get the job done. On an average size shower, this will bring your total material bill in at right around $200. This is based on entirely ripping out your old shower walls (back to the studs), and building an entirely new shower. A complete rennovation for $200. This is what I do for a living, and I can honestly tell you that you will save tons if you are handy enough to do this yourself. One side note on the pre-fab showers (fiberglass, urethane, etc) - we get a lot of calls to come out and remove mold from these types of enclosures. On most that I've seen there are a lot of corners and small nooks that moisture gathers up and sits in. Just something to watch out for should you go that method. Good luck to you, either way.

Send your message to us

MICRO-CRYATAL POLISHED PORCELAIN TILE 2

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches