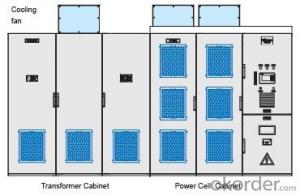

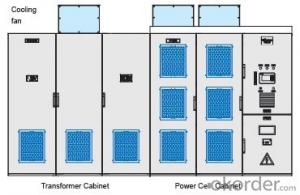

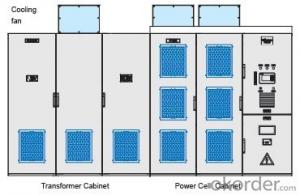

Medium Voltage Drive VFD 2250KW 6.6KV HIVERT-Y 6.6/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Torque limiting function

The torque limit function is used to accurately control and limit the torque in order to prevent overload of the motor,

electricity supply system or VFD itself. This prevents damage to the motor when stationary, for example, with a

locked rotor, when starting with high inertia or high initial friction load.

The torque limit function can also be used to prevent or limit the return of power from the motor to the VFD in the event

of an over-hauling load causing the motor speed to exceed the commanded speed.

Spinning start (Flying start)

The RMVC 5100 can automatically identify that the motor is already spinning at the moment of the start request and

institute a controlled sequence to enable the drive to pick up the spinning motor without the need to stop the motor or

the risk of a system trip. The sequence requires an initial estimate of the spinning motor speed by scanning the

motor voltage while changing the output frequency. Steps are taken to reduce the time needed to estimate the motor

speed.

Examples of when a Flying Start would be used

∙ The mechanical load causes the motor to be spinning, even though no electric power is applied to the motor.

∙ Manual reset after trip

∙ Automatic restart after a shutdown.

∙ Restart after Low-Voltage Ride-Through (temporary loss of supply power).

∙ Restart after an automatic Power Cell Bypass.

- Q: What parts of the inverter composition

- Frequency control technology is an important development direction of modern power transmission technology, with the development of power electronics technology, AC frequency conversion technology from theory to practice gradually mature. Inverter not only smooth speed, large range, high efficiency, start current is small, smooth operation, and energy saving effect is obvious. Therefore, the exchange frequency control has gradually replaced the traditional traditional slip speed, variable speed control, DC speed control system, more and more widely used in metallurgy, textile, printing and dyeing, smoke machine production lines and buildings, Water supply and other fields. However, due to the environment, the use of life and man-made operation and other factors, affecting the life of the inverter greatly reduced, while the use of a variety of failures have occurred. Here we are on the composition of the inverter and common problems and countermeasures and we discuss. Generally divided into rectifier circuit, flat wave circuit, control circuit, inverter circuit, and so on several major parts.

- Q: ASUS power adapter Acer can use it

- See whether the power adapter is suitable for notebook use, the following three conditions for reference: 1. The output voltage of the adapter is the same as that of the notebook.

- Q: Huichuan frequency converter drag a 4-kilowatt four-pole motor to change the six pole can?

- can. Re-enter the new motor parameters in the drive.Inverter motor power to 4KW, speed 980 can!

- Q: Do you want to pay attention to the number of poles of the motor when selecting the inverter?

- Such as Schneider: ATV21 for fans, ATV11 simple machine pump, ATV31 simple machine, ATV61 fan with pump, ATV71 high power machine, high torque performance

- Q: How to choose the inverter

- Look at the motor seat size is 7.5kw it, this model of the inverter manufacturers a lot of production, and are built-in brake unit, so in the function which are the same It is important that the inverter life, stability, price comprehensive consideration Mitsubishi, Panasonic, LG, Emerson, Yaskawa, Siemens and so on

- Q: Who knows how the frequency converter works

- The inverter is actually an inverter, which first turns the alternating current into direct current, and then switches the DC power with the electronic components into AC power, and the inverter is equipped with a variable frequency The frequency is adjustable in a certain range, and it is used to control the number of revolutions of the motor, so that the number of revolutions can be adjusted within a certain range.The frequency converter is widely used in the speed regulation of AC motor. Technology development direction, with the development of power electronics technology, AC frequency conversion technology from theory to practice gradually mature. Inverter not only smooth speed, large range, high efficiency, start current is small, smooth operation, and energy saving effect is obvious. Therefore, the exchange frequency control has gradually replaced the traditional traditional slip speed, variable speed control, DC speed control system, more and more widely used in metallurgy, textile, printing and dyeing, smoke machine production lines and buildings, Water supply and other fields. Generally divided into rectifier circuit, flat wave circuit, control circuit, inverter circuit, and so on several major parts.

- Q: What is the frequency converter used to do, why some motor with the inverter?

- Speed control, there are speed requirements of the place are in the inverter

- Q: Inverter 0.2KW, the motor speed requirements down to 4 turn, the motor pole 4 pole. Can the drive drive the motor?

- The first calculation: 4-pole motor, rated 1450r / min divided by 50HZ, then it is 29r / HZ. Your request is 4r / min, then the frequency of the inverter must be 0.1 less than 0.2HZ without load are compared Difficult to achieve. You can do the test, then you can try to play, if used to produce what is the best or reducer, so the inverter and the motor are good.

- Q: How to learn the inverter debugging and design parameters

- You can find the basic inverter manual, see a few times to try, under normal circumstances, the inverter on the use of manual functions such as research to understand that most of the applications are no problem.

- Q: First reduce the frequency of about one-third of the test, not the case, then appropriate adjustments!

- In the inverter in the following 18.5kw inverter will bring their own braking unit for some special occasions, such as the inverter at high speed due to production needs, must be 1 second, or less time to stop, in the stop when the frequency The internal DC bus voltage is too high, the inverter will be reported over-voltage fault, in the positive and negative connected bk-dk connected to a resistor to the inverter discharge, the inverter will not report over-voltage failure

Send your message to us

Medium Voltage Drive VFD 2250KW 6.6KV HIVERT-Y 6.6/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords