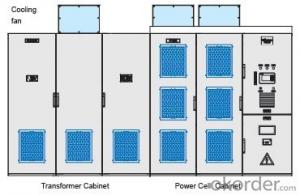

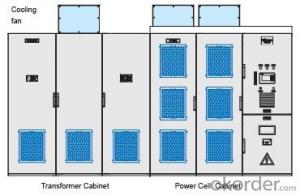

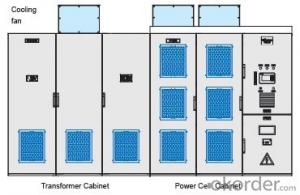

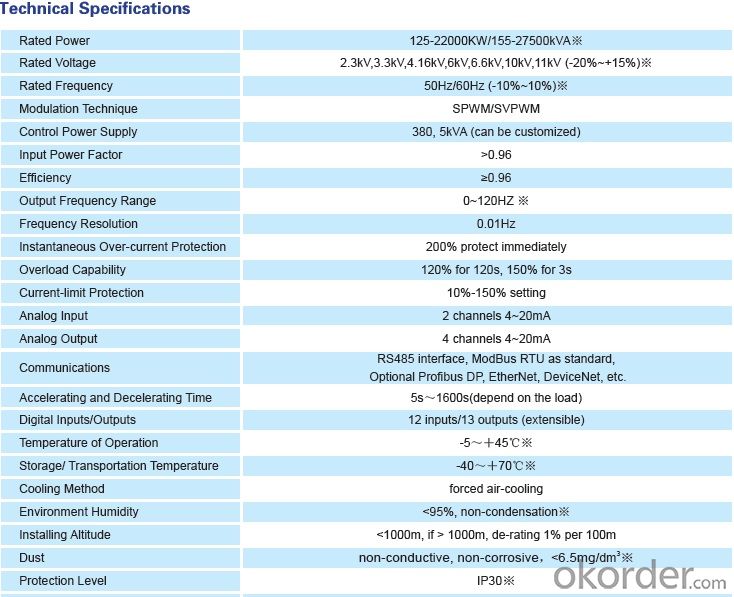

Medium Voltage Drive VFD 1400KW 6.6KV HIVERT-Y 6.6/154

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Perfect Power Output Section

The HIVERT general MV VFD adopts the power cells connected in series and voltage overlapping method (i.e. Power cells multi-level cascade technology), it can output the perfect PWM sinusoidal waveform (see Figure 2 and Figure 3). It has the following advantages:

1. No need for the additional output filter

2. Directly driving general synchronous or asynchronous motor

3. No de-rating operation on the motor

4. No dV/dt stress on the insulation of motor and cables

5. No torque ripple, extending service life of motors and mechanism

6. No cable length restriction within the acceptable voltage drop.

The general MV VFD has the following protection functions and features:

Overload and over-current

Phase loss and grounding

Over voltage

Overheat

Current limit

Redundant control power supply

Cell Bypass (optional)

Cabinet door alarm

Phase-Lock function

Synchronous Switching between VFD and Grid system

Soft start of motor

High efficiency >98% (VFD at full-load)

Electrical Isolation by the optic fiber

Built-in PID regulator

RS485 communication with the protocol, Modbus as standard, optional Profibus-DP, Ethernet,etc

Accurate fault records, easy to check fault history

Compact structure and layout, customized design is available

- Q: How to view the parameters of the notebook power adapter on your computer

- The correct way to use a laptop power adapter 1. Try to avoid use in outdoor or harsh environments to prevent the adapter from being exposed or damp. 2. When you are not using the adapter, please unplug the power plug. Because, for a long time the power will let the adapter has been in working condition, will affect the end of life. 3. Although the adapter is a broadband operating voltage, marked from 100V-240V can be, but if the voltage is extremely unstable in the case of use, the same will cause damage to the power adapter

- Q: The laptop power adapter is burned

- To be sure, the power adapter has a problem ~ ~ I suggest you if the warranty period to go after the sale of a ~ ~ If the insurance on Taobao Amoy on a ~ ~ ~

- Q: Three-phase asynchronous AC motor speed control method

- Third, cascade speed control method Cascade speed regulation refers to the winding motor in the rotor loop into the adjustable additional potential to change the motor slip, to speed control purposes. Most of the slip power is absorbed by the additional potential in series, and the additional device is used to return the absorbed slip power to the grid or to convert the energy. According to the slip power absorption and utilization, cascade speed can be divided into motor cascade speed, mechanical cascade speed control and thyristor cascade speed form, the use of thyristor cascade speed, which features: Can be transferred in the speed of the process of slip loss back to the grid or production machinery, the higher efficiency; Device capacity and speed range is proportional to the investment province, for the speed range of 70% -90% of the rated speed of production machinery; Speed ??control device failure can switch to full speed operation, to avoid shutdown; Thyristor cascade speed power factor is low, the greater the impact of harmonics. This method is suitable for use in wind turbines, water pumps and rolling mills, mine hoists, extruders.

- Q: Can the inverter stop intermittently during operation? If so, how to connect and set up

- One of these terminals is a common terminal, which leads from the common terminal and is connected to the corresponding terminal via the relay contact

- Q: ASUS power adapter Acer can use it

- 3. The size of the joint is appropriate. (If the connector is too loose, will be bad, excessive fever.) If it is for DELL and HP / Compaq and other notebook power adapter, will involve a decoding problem. Please pay attention when the pro to buy. Acer and Asus are not yet available. It is said that the market is also very popular universal adapter, a friend bought a LVSUN brand universal adapter LS-PAB90-BC10, with eight joints. Adapter has a liquid crystal display, you can also automatically switch the voltage, very smart, with more than a year, has also been used.

- Q: Can the notebook's power adapter be mixed?

- At present, the market sales of notebook power is generally 90 watts and 65 watts two, using integrated graphics, or configure the low-end notebook, usually 65 watts. Using the independence was, the configuration of high-end, or the game audio and video of this, are generally 90 watts. If the laptop's power adapter is damaged can not be used, it is best to repair the department as soon as possible to repair. If it is for emergency, before using the two adapters to check the output power and current and voltage are conceded, as the adapter input current and voltage is not the same, should be the general household voltage is 220V, so almost all of the notebook power The adapter is 100-240V ~ 1.5A words, as long as the output current and voltage values, and wattage equal, and then one is the same interface, you can mix. In general, the voltage is stable, the output wattage is the same, the notebook is basically no harm.

- Q: Notebook plug in the power adapter lights, but can not open the machine

- Put the board under the re-installed, try and then boot. Asked: This is the case of removal, with the battery can boot answer: Then put the battery on the computer, and then use the power splitter to see if you can. If not I do not know, is the computer question to ask: This can be

- Q: Will the asynchronous motor pole change the number of speed control can also be combined with the frequency converter

- Of course, because the factors that determine the speed of asynchronous motor power supply voltage, frequency and motor pole pairs, so asynchronous motor speed can be achieved by changing the number of magnetic pole pairs, but this method needs to make a greater motor changes, Trouble, and change the number of poles can only achieve a single speed change;

- Q: What is the difference between AC and DC frequency converters?

- Advantages and disadvantages: Advantages: inverter air conditioner with variable frequency power supply, inverter compressor, electronic expansion valve and microcomputer technology, the organic combination of air conditioning to further improve the performance, the use of room temperature fluctuations, better comfort, the better Power supply voltage fluctuation is not sensitive, the compressor starts, the general non-stop, cooling capacity in the range of 35% to 117% change, to avoid the frequent open air-conditioning, to extend the life of the compressor, while efficient, Features. Disadvantages: the price is more expensive, compared with ordinary air conditioning, about 1/3 to 1/4 of the price, at the same time, because the inverter air conditioner control system and frequency conversion system is more complex, higher requirements for components, compared to ordinary air conditioning , Inverter air conditioner failure rate is high, and, due to the use of frequency conversion technology, at the same time, will produce harmonic pollution. What is DC inverter air conditioner? DC inverter air conditioner is relative to the AC inverter air conditioner, in fact, its name is not correct, because the DC and no frequency, it is by changing the DC voltage to adjust the compressor speed, thus changing the air conditioning cooling capacity, It can only be said to be a DC variable speed air conditioning, not strictly in the sense of inverter air conditioner.

- Q: Is the laptop power adapter hot?

- Third, the power of the nominal voltage than my books the battery voltage is much higher, not an accident, right? First of all, to know is that the power supply to the books and the battery power supply to the notebook is different. Battery-powered, the battery output is pure DC, very clean, the battery voltage is neither possible nor need to design a high, lithium battery chemical properties determine a cell output voltage can only be about 3.6V, so Many batteries are used in three cascade way, 10.8V also became a very popular battery voltage. Some batteries are slightly larger than the integer value of 3.6V, such as 3.7V or 11.2V, etc., in fact, to protect the battery. Power supply, the situation is more complex, first of all need to add voltage to further regulation filter to ensure that the power performance is not very good in the case of stable work, the voltage regulator after the two parts of the city, all the way to the work of the power supply , The other way to the battery charge to the part of the power supply to the battery when the same power supply, and the part of the battery charge through the battery charge control circuit can be added to the battery, the control circuit can be very complex, so the power The voltage must be greater than the cell voltage to have sufficient capacity to supply the charge control circuit to the units. Finally the voltage actually added to the cell will never be the nominal voltage of your power supply. Rest assured.

Send your message to us

Medium Voltage Drive VFD 1400KW 6.6KV HIVERT-Y 6.6/154

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords