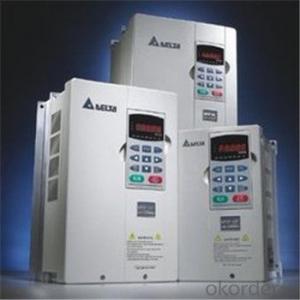

3 Phase Frequency Converter, Frequency Inverter, VFD and VSD for Induction Motors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

EDS1000 series Multi-function universal frequency inverter has 150% rated torque at 1 Hz, meeting the requirement of low noise, high torque, low electromagnetic interference and covering three voltage grades: 220V, 380V and 690V. This kind of frequency inverter is widely used in applications which require high-speed control accuracy, rapid torque response, and high performance at low frequencies.

Features

Infineon IGBT module (German brand) adopted, featuring less failure rate and smaller size compared with single-transistor inverter.

Fujitsu CPU (Japanese brand) adopted, characterizing rapid and stable calculation.

Mini size, suitable for all kinds of applications

Abundant DI/DO and AI/DO

150% rated torque at 1 Hz frequency

Built-in PID controller, realizing constant pressure (flux etc.) “One inverter drives multiple devices” control (optional function)

16 (maximum) section speed control

0-20KHz pulse input output interface

Spinning traverse function

Automatic voltage regulation (AVR) and automatic current limiting function

RS485 communication interface (optional part)

Multi-frequency input channel selection

Closed-loop running control

Keypad parameter copy function and password protection function

Crystal English display keypad and English operation content indicating.

Applications

Textiles, plastics, blower, pump, ceramics, electronics, numerical controls, foods processing, weaving, transportation machine, metallurgy machine, constant pressure water supply, air compressor, air conditioner, music fountain, paper making, chemical mechinery etc.

FAQ

Q 1. what's the payment term?

A. We accept T/T, L/C, WEST UNION

Q 2. What's the delivery time ?

A. Normal model,0-3days,

For big order(more than 10,0000 usd),it takes about 7-15days. Customer make will be longer but with not over 15 days.

Q 3. What is the standard of package?

A. Export standard package or special package according to customer requirement

- Q: What is the difference between the electronic governor and the frequency converter on the motor speed regulation?

- Probably the wider range of frequency converter applications! There is a more comprehensive protection of the motor on the inverter

- Q: How can a variable speed multi - speed three - phase asynchronous motor be controlled by a frequency converter?

- With the inverter control, then you do not need multi-speed motor, because the inverter can directly control the motor speed, if the two together, the formation of a waste.

- Q: Asus notebook power adapter how to open

- Can only be forced to open the pants and other things wrapped around the line on the line suggested that do not casually demolition

- Q: Will the 75KW4 pole motor can be used to increase the speed of the inverter?

- can! The output frequency of the inverter is higher than 50HZ, the speed of the motor is higher than the rated speed. In a certain range, the higher the frequency of the inverter, the faster the motor speed.

- Q: Yaskawa inverter reported base blockade what is the reason?

- For example, when you stop the inverter, there will be a signal to the inverter, and then the inverter will base block, cut off the output, the motor will no longer work; when you need the inverter work, There is a signal to the inverter, the inverter to cancel the base blockade, it is normal work,

- Q: How many types of CVT are classified?

- CVT (Continuously Variable Transmission) technology that is continuously variable technology, which uses the belt and the working diameter of the main and driven wheel to match the power to transfer, you can achieve a continuous change in transmission ratio, resulting in transmission and engine conditions of the most Good match

- Q: What is the difference when using inverter frequency conversion ordinary motor and variable frequency inverter motor

- 2, the ordinary asynchronous motor is the cooling fan and motor spindle connection, the motor speed determines the cooling fan speed, low frequency when the motor rotation is slow, so the motor temperature rise is the principle.

- Q: What is the meaning of the bipolar polarity in the inverter ah There is a +10V signal input is a -10V What is the meaning of ah?

- Analog signal input: Reference setting Input voltage Positive terminal (0 --- 10V)

- Q: Three motors, if coupled with the governor speed, is it necessary to add the inverter?

- ?Fifth, the hydraulic coupler speed: hydraulic coupler is a hydraulic transmission device, generally composed of the pump wheel and turbine, when the pump wheel in the prime mover driven under the rotation, in which the liquid is driven by the blade and rotation, in the Under the action of centrifugal force along the outer ring of the pump wheel into the turbine, in the same turn to the turbine blades to thrust, to drive the production machinery operation. Through different hydraulic (lubricants and turbines) to achieve speed.

- Q: Why G120 inverter to be equipped with 4-pole motor?

- Not necessarily must be equipped with four-pole motor, 2 pole, 6 pole, 8 pole, 12 pole can be used. As long as there is no problem with attention to current matching. Because the amount of 4-pole motor is the largest, all the frequency converter, are based on 4-pole motor for the control model design.

Send your message to us

3 Phase Frequency Converter, Frequency Inverter, VFD and VSD for Induction Motors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords