Variable Frequency Drive 3.3KV 630KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General

CNBM high Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity.

The series are compatible with all types of three-phase medium voltage asynchronous motors.

Specifications

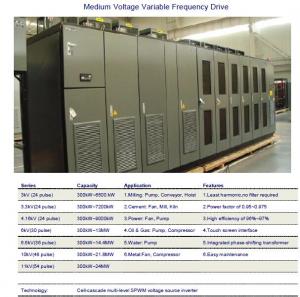

Variable Frequency Inverter

1.3KV ~11KV AC Driver Inverter

2.Suitable for motor speed regulation

3.Energy saving solutions

Specification and advantages :

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

5.The medium voltage circuits are linked with the controller by the optical fibers,which keep the controller safe and away from the disturbance.

6. The complete fault monitor circuit, accurate fault alarm and protection.

7. Integrated cooling blower

8. The control logic can be conveniently changed with the help of the integrated PLC.

9. Offer both field control and remote control in monitor station, providing convenient controlling options.

10. Support most of the industrial standard protocols (Profibus, Modbus, TCP/IP, etc.)

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: Notebook power adapter on how to look at power

- then the same formula can be used to calculate: power (unit: W) = voltage (unit: V) × current (unit: A). For example: the power adapter only identifies the output voltage is 20V, the output current is 4.5A, then we set a formula to know the output power is 20 × 4.5 = 90W.

- Q: Can the HP laptop's power adapter be universal?

- Hello! Thank you for choosing HP products. Based on your description, we recommend that you refer to the following information: Notebook power adapter is generally depends on the adapter interface, input and output of the parameters are consistent, it is recommended that you see the parameters on the power adapter to see if the same, if the agreement then the two machines can be common adapter.

- Q: The laptop's power adapter is broken how much it costs

- Hello, this is not very expensive Generally in 80 or so, you can go to the Internet to see the model, and then to the store to buy the price on it.

- Q: Variable frequency conversion frequency difference characteristics based on,

- Whether it is variable speed control, or string resistance speed, are the cost of energy consumption.

- Q: 22kw.2 pole fan can use Fuji inverter?

- Fan with Fuji? Money more people silly ... no comment ..

- Q: 30 kW 6 pole frequency motor torque is how much

- To know what is the use of ah, the inverter motor is the same with the ordinary motor, but to prevent the operation of a low speed plus a fan

- Q: Siemens g120 inverter torque limit what is the meaning

- For example, you have 100kg of power, but you can send the power and you lift the weight of the object, if the object weight of 10kg, you can only use 10kg of power.

- Q: What is the IGBT? Our inverter IGBT fried,

- Popular point is a switch, give him the signal to continue in accordance with a certain order switch, the DC through the switch into a change in the exchange of alternating current, different frequency.

- Q: Why G120 inverter to be equipped with 4-pole motor?

- On the upstairs that the motor parameters to be set on the possible, such as voltage, current, power, power factor, rated efficiency, rated frequency, rated speed, motor overload factor

- Q: 380V 2 pole motor can use the inverter?

- Special attention, variable frequency motor with the ordinary different, easy winding film damage

Send your message to us

Variable Frequency Drive 3.3KV 630KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches