Variable Frequency Drive 3.3KV 850KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction :

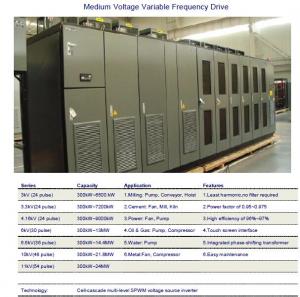

4.16kV /6kV Series VFD

3kV /3.3kV Series VFD

6.6kV Series VFD

10kV / 11kV/ 13.8kV Series VFD

Features :

Medium Voltage Variable Frequency Drives are designed to be highly reliable with high-performance, yet easy to use.It can satisfy users' need for changing the speed of fans or pumps,as well as improve the productivity. The series are compatible with all types of three-phase medium voltage asynchronous motors. The VFDs which are compatible with medium voltage synchronous motors are in the final stage of development. series of medium voltage VFD manufactured with the new type of IGBT with microprocessor control have the qualities as follows:

1. Voltage resource VFD, direct input of 3,3.3,4.16,6,606 and 10 kV,direct output of3,4.16, 6,6.6 and10 kV,no output transformer necessary. High input power factor, low harmonic current, no power factor corrective capacities and harmonic filters required.

2. Sinusoidal multi-level PWM output waveform, no output filter required, can be directly connected to standard induction motor,no harm to the insulation of the cable or the motor, low harmonics of the motor, reduction of vibration of the shafts or the vanes,with the maximal length of the output cable of 1000m.

3. Friendly human-machine interface.

4. Modular design of the power circuits simplifies maintenance routine.

5.The medium voltage circuits are linked with the controller by the optical fibers,which keep the controller safe and away from the disturbance.

6. The complete fault monitor circuit, accurate fault alarm and protection.

7. Integrated cooling blower

8. The control logic can be conveniently changed with the help of the integrated PLC.

9. Offer both field control and remote control in monitor station, providing convenient controlling options.

10. Support most of the industrial standard protocols (Profibus, Modbus, TCP/IP, etc.)

11. Compatible with industrial standard signal of 0-10V/4-20mA

12. Able to operate at either open loop control or closed loop control status with the integrated PID regulator.

13. Complete system parameter setup function of VFD

14. Easy installation

15. Excellent performance/price ration

Specification

Model | A03/050~ | A03/100~ | A03/175 ~A03/220 | A03/220~A03/400 | A03/220~A03/610 |

Capacity(kVA) | 250~630 | 630~900 | 900~1150 | 1150~2000 | 2000~3125 |

Rated output current (A) | 50~100 | 100~175 | 175~220 | 220~400 | 400~610 |

Motor power (kW) | 200~400 | 400~710 | 710~900 | 900~1600 | 1600~2500 |

Input frequency | 45Hz~55Hz | ||||

Rted input voltage | 3000V±10% | ||||

Input power factor | 0.95 (>20%load) | ||||

Efficiency | 0.96 with rated load | ||||

Output frequency | 0.5Hz~120Hz | ||||

Frequency resolution | 0.01Hz | ||||

Overload capacity | 120% 1 min, 150% immediately | ||||

Analogue input | 0~10V/4~20mA | ||||

Analogue output | 0~10V/4~20mA | ||||

Acceleration/deceleration time | 0.1~3000s | ||||

Digital output/input | expanded according to requirement | ||||

Ambience temperature | 0~40°C | ||||

Storage/transport temperature | -40~70°C | ||||

Cooling | air cooling | ||||

Ambience humidity | <90% without condensation | ||||

Altitude | <1000 m | ||||

IP class | IP20 | ||||

Size(mm)(W×H×D) | 3300×2480×1200 | 4900×2480×1200 | 6000×2580×1300 | ||

Weight (kg) | 3000 ~5000 | 5000 ~7300 | 7300~9200 | ||

- Q: In the case of the inverter, why can not the normal operation after removing the gearbox? The motor is 4 pole.

- If there is a load, it may be less than the torque. So it can not run.

- Q: What parts of the inverter composition

- The main converter are: rectifier module, inverter module, capacitor, driver board, motherboard, shell composed of these parts!

- Q: Can the laptop's power adapter be used for years?

- Generally 3 to 5 years is not a problem, good quality can be used for 10 years. Power adapter is a small portable electronic equipment and electrical and electronic power supply conversion equipment, generally by the shell, power transformer and rectifier circuit, according to its output type can be divided into AC output and DC output type; by way of connection Divided into wall and desktop. Extensive support in the phone son machine, game consoles, language repeaters, Walkman, notebook computers, cellular phones and other equipment.

- Q: Laptop power adapter in the ring is how is it?

- Notebook power adapter generally use the switch circuit, the output 12V DC power supply, as the notebook DC / DC converter circuit power supply; In the switch circuit, the most prone to "creak" sound is the switch transformer coil (ringing), or high-voltage filter capacitor (fire);

- Q: 2 pole 0.75 kW motor can increase the speed through the inverter?

- if the 4-pole motor to rise to 2-pole motor frequency, The frequency of the motor rises to about 100 Hz, which is easy to implement for the frequency converter.

- Q: Pump frequency converter instantaneous restart and restart the problem

- Inverter speed: Based on the advantages of speed control, energy saving and reliable operation, the frequency converter has gradually replaced the traditional variable speed, electromagnetic speed and voltage regulation. In the introduction of PWM flux vector control of the inverter a few years later, the end of 1998 and the emergence of DTC control technology inverter. ABB's ACS600 series is the first generation of DTC technology using the inverter, it can open the ring speed and torque for accurate control, and dynamic and static indicators have been better than PWM closed-loop control indicators. Direct torque control to measure motor current and DC voltage as input to the adaptive motor model. The model produces a set of precise torque and flux actual values ??every 25μs. The torque comparator and flux comparator compare the actual values ??of torque and flux with the reference values ??for torque and flux to Determine the optimal switch position. It can be seen that it is through the torque and magnetic flux measurement, instantly adjust the inverter circuit switching state, and then adjust the motor torque and magnetic flux, in order to achieve the purpose of precise control.

- Q: What is the laptop power adapter? Is it the battery?

- Notebook power adapter, of course, is not referring to the laptop battery.

- Q: Master Hello a machine requires 500 speed matching 6-pole motor frequency converter transferred to about 28HZ

- The belt rotation is calculated by the speed ratio. The current transferred to the motor by the inverter is approximately equal to the rated current of the motor, ie the motor's power is maximized.

- Q: Whether the inverter can control the start and stop of the horizontal monopole centrifugal pump

- Hi, the inverter control is no problem. You need to select the inverter by the load characteristics of the centrifugal pump, consider: Centrifugal pump rated working current, overload capacity, parking whether there is emergency stop request. I used the inverter to control the horizontal centrifuge some time ago.

- Q: Why the notebook power adapter can not be universal

- First, the interface is different Most laptop power adapter brands have different interfaces, which means that other brands of power adapters can not be plugged into your laptop for power supply. The interface is relatively safe, because at least you will not plug in the current or voltage does not meet the power adapter to the laptop power supply, which led to computer hardware damage.

Send your message to us

Variable Frequency Drive 3.3KV 850KW VFD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches