Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

It can be applied not only in the interior use but also in the outdoor walls. It has low water absorption rate and high impact resistant ability. These advantages make it suitable for any purposes of applications.

Product Applications:

1) Old and new building curtain walls, exterior walls and other outdoor systems

2) European and American styles of architecture and high-end villa roof

3) Indoor hall, office, building facade and podium

4) Kitchen, bathroom, bathrooms, changing rooms and other damp places

5) Subway stations, tunnels and underground works

6) Interior wall decoration system

7) High quality requirements of the ceiling

8) Environmental requirements, particularly Germany occasions

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

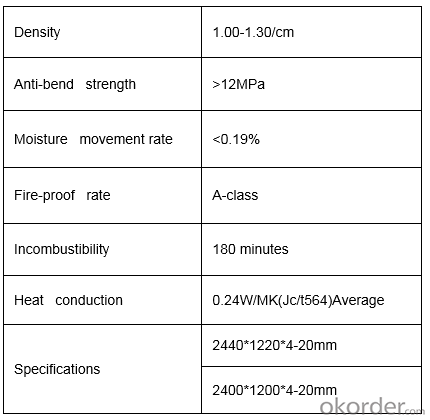

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q: Please guide you, the decoration of the indoor use of calcium silicate board and integrated aluminum slab plate, which kind of ceiling to do good? Their advantages and disadvantages? Thank you!

- Calcium board can make a lot of shape, suitable for complex decoration, but fear of water. Suitable for business facade!

- Q: The difference between calcium silicate board and plywood

- The use of a long time there are drums, brittle, yellowing, cracking problems, in a fire is not, although it may add fire agent compound, but in high temperature will release toxic gases, so the safety performance is not good, and calcium silicate Board is completely inorganic and wood fiber (asbestos fiber now many manufacturers have no use, radiation) composite, high strength easy processing, life and building life is equal, strong fire resistance, the maximum fire temperature of 1050 degrees.

- Q: Ceiling with gypsum board or calcium silicate board?

- The shape of the ceiling less With calcium silicate board. Hardness. Waterproof and waterproof. Not easily deformed. Fire performance is better. 2 are not much price.

- Q: Calcium silicate board and noise board which sound insulation effect is good

- Sound insulation board is collectively, calcium silicate board is a product name, calcium silicate also has calcium silicate sound insulation board, but you look and what kind of board than the best effect of wood should be good

- Q: Silicon calcium board can be used for external walls

- The main reason is its advantages: light, moisture-proof performance is good, easy to change color, high hardness, good sound insulation performance. The calcium silicate board also has obvious shortcomings: the installation is not easy to replace, the installation of the use of iron keel, the price is more expensive and easy to break, slit. But now there are external walls with calcium silicate board, but from the cost point of view, the proposed external walls or do not use calcium silicate board

- Q: Is the calcium silicate board attached directly to the wall?

- (Long time will fall off) calcium silicate board and cement board is two kinds of boards, cement board is made of mixed materials, (house demolition of waste) calcium silicate board size is generally 1220 mm * 2440 mm calcium silicate Plate is not suitable for wall partition, because of its high hardness, easy to break. If you do the wall, it is recommended to use gypsum board. Home generally do not use carpentry production wall. Calcium silicate board for large ceilings, and prone to moisture. Ask: I was doing supermarket decoration, just started. The The The The The Supermarket on the ground floor, processing the wall side of the party does not allow brick walls (including hollow brick), because the wall under the beam, fear of bearing a problem. Several of these processing must be linked to the brick, because to moisture and moisture.

- Q: Calcium silicate board fire board can do air conditioning ducts do

- Thermal insulation Calcium silicate board has a good thermal insulation properties, 10mm thick wall insulation performance is better than ordinary brick wall effect, but also has a good sound insulation long lasting Calcium silicate board performance is stable, Naisuan Jian, not easy to corrosion, it will not be moisture or insects and other damage, can guarantee a long service life.

- Q: Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- If you are a large area of the ceiling, or use strong, no need for a small area

- Q: Calcium silicate board surface putty Why crack?

- Usually in the board and board transfer place, very prone to cracking. And then the construction of such a transfer of the time, we must do anti-cracking treatment. If cracking has occurred, it will need to be shoveled along the cracks, and then fill with a dry coating, while the bandage to play a role in anti-cracking.

- Q: Calcium silicate sound - absorbing panels with what inspection lot

- According to the use, the state has the best reverberation timetable for all kinds of halls, and the reverberation time of the audible field can be checked by the reverberation. With ordinary fire test whether the fire standards.

Send your message to us

Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords