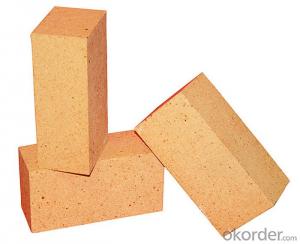

Low Creep Checker Bricks Hot Blast Furnace Low Creep High Alumina Andalusite Checker Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

13 Refractory plants locate in 9 different cities

15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry

Annual production capacity is over 400,000 tons.

Product Name: Low Creep High Alumina Andalusite Checker Brick for HBF.

Features:

High thermal shock resistance

Low creep

Technical Data Sheet for DRL-145

ITEMS | UNIT | VALUE |

Al2O3 | % | ≥65 |

Fe2O3 | % | ≤1.5 |

TiO2 | % | ≤0.6 |

Bulk Density | g/cm3 | ≥2.5 |

Apparent Porosity | % | ≤23 |

CCS | Mpa | ≥55 |

0.2 Mpa RUL , 0.2MPa | ℃ | ≥1550 |

Refractoriness | ℃ | ≥1790 |

0.2 Mpa Creep Rate 1450℃×(0~50)h , 0.2MPa 1450℃×(0~50)h | % | ≤0.8 |

Thermal Shock Resistance 1100℃, water ,1100℃ | cycle | ≥30 |

Product Photos of 7-hole Low Creep Checker Bricks

Our workshop

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: What is fireproof concrete?

- According to the different properties of fire resisting and heat resisting concrete, they can be divided into silicate, aluminate, phosphate, sulfate, chloride, sol and organic substance, fireproof and heat-resisting concrete, etc.. The following are mainly used silicate, aluminate, phosphate, sulfate fire, heat-resistant concrete.

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- The other is in large enterprises and individual has the unique advantage of the small enterprises, with independent technology system, production equipment advanced, there are certain funds set up to deal with risk, timely reform, such enterprises compared to a few years ago the productivity and sales or have declined, but overall is still in the stage of production increased steadily.

- Q: What is the difference between corundum and high alumina??

- The main components of high alumina brick are high alumina bauxite, mullite and partial corundum sand.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- In the meantime, the free silica content of silicon brick is as high as 90% above. Therefore, the most serious damage is silicon brick, followed by clay brick, high alumina brick, magnesia brick and so on.

- Q: What is the difference between high alumina brick and clay brick?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What causes breakage of refractory bricks?

- There are many factors that lead to the damage of refractory brick, can be divided into: the chemical loss (e.g. salt penetration, redox phenomenon), heat loss (burning, thermal shock), mechanical loss (kiln deformation, thrust, brick masonry quality etc.).

- Q: Which thermal shock stability of clay brick and high alumina brick is good?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.Thermal shock stability is much better than clay brick.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

Send your message to us

Low Creep Checker Bricks Hot Blast Furnace Low Creep High Alumina Andalusite Checker Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords