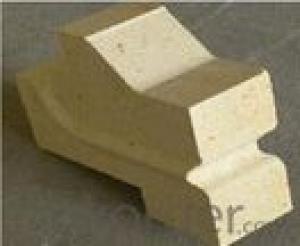

Mullite Brick for Hot Blast Stove with Low Creep Andalusite

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

热风炉用低蠕变红柱石砖

项目 | LHZ—65 | LHZ—60 | LHZ—55 | LHZ—50 |

Al2O3, % | 65 | 60 | 55 | 50 |

显气孔率,% | 20 | 20 | 20 | 20 |

体积密度,g/cm3 | 2.60 | 2.50 | 2.50 | 2.40 |

常温耐压强度,MPA | 50 | 50 | 50 | 50 |

蠕变率,%(20—50h) | 0.2 | 0.2 | 0.2 | 0.2 |

重烧线变化,%(1400℃x4h) | 0—0.3 | 0—0.3 | ±0.2 | ±0.2 |

荷重软化开始温度,℃ | 1650 | 1600 | 1600 | 1580 |

Specification:

Product characteristics; Hot blast stove with low creep brick of andalusite using selected andalusite, corundum, mullite as main raw materials, through high pressure molding, high temperature sintering, andalusite in 1350 ℃ formation of mullite products surface with strong "welding" effect, so that the products good thermal shock resistance, high refractoriness under load, high temperature creep resistant performance is good, good thermal shock resistance, is a Dutch type technical characteristics of hot blast stove with refractory.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Compressive strength, volume density, flexural strength, thermal shock resistance, high temperature load, creep temperature, refractoriness, etc.. There should be GB

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.Sintering temperature: the sintering temperature of mullite is low. So the cost is low because of this, so alumina ceramic is basically not used for floor tiles - unless it's too rich to burn.Heat shock resistance: the thermal shock resistance of mullite is higher than that of alumina.High temperature creep properties: the high temperature creep of mullite is higher than that of alumina, so mullite can bear higher weight at high temperature, and alumina is less.Resistance: alumina ceramic resistor is higher than mullite, so it is used as high-voltage insulators.

- Q: What is the price of refractory bricks?

- The refractory insulating brick generally refers to light brick, normal furnace lining are using this brick kiln will not increase the weight, and good heat insulation effect and ordinary insulating brick production are made of clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating firebrick, diatomite insulating refractory brick, the use of light heat insulation brick can increase the use of space, and good insulation effect

- Q: Mullite bricks in alumina alumina is what?

- Quality solutionsMullite brick:With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- In the presence of excess EDTA in the acidic medium, the aluminum is complexed with EDTA, and the remaining EDTA is complexed with lead salt, and then the EDTA complexed with aluminum is replaced by sodium fluoride, and the lead salt is substituted...

- Q: The introduction of mullite brick

- High alumina refractory with crystalline mullite (3Al2O3, 2SiO2) as the main crystal phase.

- Q: Mullite brick

- Mainly used for hot blast stove of blast furnace and furnace bottom and furnace, glass furnace regenerator, sintering kiln, petroleum cracking dead lining system.

- Q: The difference between the high aluminum corundum brick and corundum mullite brick

- Tiles are called floor tiles, floor tiles, polished tiles and glazed tiles are glazed tiles, bricks are samples of all kinds of tiles, ceramic tiles will be placed in the tile shop, tiles are also divided into outer wall tiles and inner wall tiles, modern brick and antique brick

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- Mullite refractory bricks can be used in construction, but their price is too high. We choose high alumina brick to meet the demand.

Send your message to us

Mullite Brick for Hot Blast Stove with Low Creep Andalusite

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords