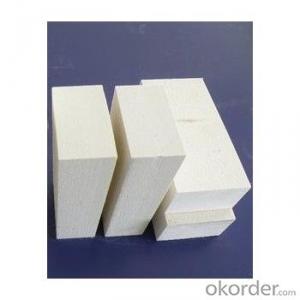

Mullite Brick - Low Apparent Porosity Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Wood carton box:10pcs/carton wooden pallet:544pcs/pallet |

Delivery Detail: | 15 Days deposit |

manufacture low apparent porosity mullite insulating fire brick for heating furnace

Product Description

Low apparent porosity mullite insulating fire brick for heating furnace is a kind of insulation refractory product taking mullite as main raw materials.It enjoys high temperature resistance, high strength, nd low thermal conductivity. Besides, it can directly contact the flame, and can be used in lining of a variety of industrial furnaces.

key features

1.Low density High purity

2.Low iron Low thermal conductivity

3.Excellent thermal shock resistance

application

1.Glass industries iron & steel industries

2.Ceramics industries non-ferrous metals industries

3.Electrolytic Aluminum industries power generation industries

4.Heat surface fireproof lining other fire-proof back lining

Technical Data

Index of refractory Mullite lightweight brick | ||||||

item | AL2O3% | Fe2O3% | Bulk Density, | Cold Crushing | linear change | Thermal conductivity |

g/cm3 | Strength Mpa | on reheating/% | /W.(m.k)-1(350℃) | |||

P30-6 | ≥52 | ≤1.0 | <0.6< p=""> | ≥1.5 | ≤1.0(1350°C,12h) | 0.2 |

P40-8 | ≥55 | ≤0.8 | <0.8< p=""> | ≥2.5 | ≤1.0(1400°C,12h) | 0.28 |

P50-10 | ≥60 | ≤0.8 | <1.0< p=""> | ≥4.0 | ≤1.0(1500°C,12h) | 0.33 |

P60-12 | ≥72 | ≤0.8 | <1.2< p=""> | ≥2.5(1.2) | ≤1.0(1650°C,12h) | 0.44 |

P60-135 | ≥72 | ≤0.8 | <1.35< p=""> | ≥3.5(1.4) | ≤1.0(1650°C,12h) | 0.48 |

P65-155 | ≥76 | ≤0.8 | <1.55< p=""> | ≥3.8(1.6) | ≤1.0(1650°C,12h) | 0.53 |

P70-165 | ≥80 | ≤0.6 | <1.65< p=""> | ≥6.0(2.8) | ≤1.0(1700°C,12h) | 0.7 |

P80-175 | ≥85 | ≤0.5 | <1.75< p=""> | ≥6.0(2.8) | ≤1.0(1750°C,12h) | 0.72 |

other products

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- The mineral composition of the high alumina brick is determined by the bauxite used. The mineral composition of the clinker is usually mullite, corundum and glass. The theoretical composition of mullite is Al2O371.8%, SiO2 28.2%, and its melting decomposition temperature is 1840 DEG C. With acicular crystal, network cross structure, high temperature state showed better strength. Corundum in the form of alpha -Al2O3, melting point of 2050 degrees, hardness of Mohs 9, showing a granular and columnar crystal, has good chemical stability, acid, alkaline slag have a certain resistance. Based on the composition of mullite minerals, the phase composition of high alumina brick can be judged according to the content of Al2O3.

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Is there a mark on the contract? Mark the items as required by the contract.

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- The floor tiles are not made exclusively of alumina. Pure alumina ceramics are expensive.

- Q: Mullite bricks in alumina alumina is what?

- Quality solutionsMullite brick:With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- Under strong alkaline conditions, aluminum is separated from other metal ions by the amphoteric nature of aluminum.

- Q: The introduction of mullite brick

- High alumina refractory with crystalline mullite (3Al2O3, 2SiO2) as the main crystal phase.

- Q: Mullite brick

- Mainly used for hot blast stove of blast furnace and furnace bottom and furnace, glass furnace regenerator, sintering kiln, petroleum cracking dead lining system.

- Q: The difference between the high aluminum corundum brick and corundum mullite brick

- Wall tiles and floor tiles are collectively referred to as ceramic tile flooring

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- In many architectural design, high-rise fire rating is placed in the important position of the topic, especially when the floor height is more than 20 layers, we have more stringent requirements for the choice of fire resistant materials. The building wall, kitchen flue, boiler flue, flammable zone must use a firewall barrier, in many refractory refractory brick is the product of choice for fire resistance of refractory brick masonry is more stable.

Send your message to us

Mullite Brick - Low Apparent Porosity Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords