Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Brief Introduction of Our Company

Our company specializes in manufacturing cold-pressing steel profile mechanical equipment, cold-pressing structural section, high- frequency welding machine set, inert gas arc welding machine set, pipe bending machine, metal pipe circular saw machine, chamfering machine, pipe end forming machine, conveying appliance, elevator guide rail assistant processing equipment, dust-removing equipment, all kinds of conveying equipment parts and non-standard machinery products.

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

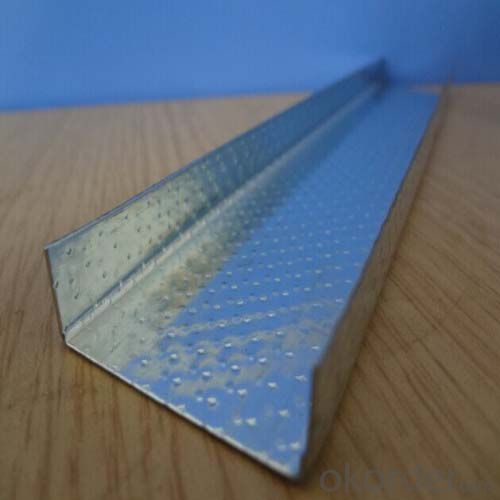

3.Image

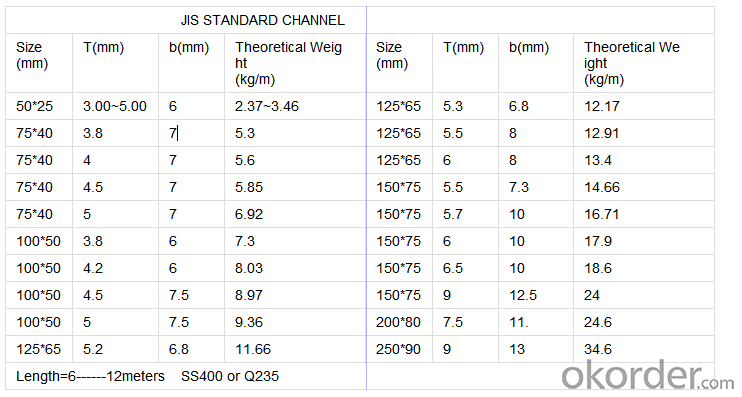

4.Detailed Specification

5.FAQ

Package: Standard seaworthy export packing.4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection. Outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Usage: Galvanized steel coil products are mainly applied to building, light industry, automobile, agriculture and animal husbandry fishery . In construction industry, it is mainly used to produce anti-corrosion of industrial and civil building roof, roof grille. In light industries it can be used as appliances shell, civil chimney, kitchenware, etc Farming fisheries mainly used as food storage, the seafood frozen processing equipment of meat, Business mainly used as materials of storage, packing equipment etc..

- Q: Light steel keel ceiling The first main keel distance from the wall should be how much? To be specific.

- W fixed spacing of the boom 900-10OOmm pitch, in the event of beam and pipe fixed point is greater than the design and procedures requirements, should increase the fixed point of the boom. W is not on the ceiling, boom length is less than 10OOmm, you can use φ6 boom, if more than 10OOmm, should be used φ8 boom, should also set the reverse support. W Master's ceiling, boom length is equal to 10OOmm, you can use φ8 boom, if more than 10OOmm, should be used φ10 boom, one end of the boom with L30X30X3 angle welding (corner of the aperture should be based on boom and expansion Bolt diameter to determine), the other end can be tapped out with more than 100mm screw, you can also buy finished screw welding.

- Q: Light steel keel will rust?

- Buy the difference between the big ah, that is the difference between the grandfather, such as the United States is the United States is such a marketing before entering China? Shame lost to the United States, not only lost the face of the Chinese people, but also tarnished the Americans Finally paid the brand to pay the full amount, then pay the face, and only buy this brand of ink to know.

- Q: Light steel keel ceiling steps? How to use wood?

- Steps above almost with the board may be a special shape all with light steel keel can but can be very troublesome

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The difference is simple, Use the wood to do keel cheap, but not strong; with Cyclobalanopsis keel firm, really expensive. In fact, the wood is not so strong. Qinggang keel is also not where you go.

- Q: Light steel keel ceiling cracks how to deal with

- Another situation: the top of the hole inside the ventilation holes (into the wind), or bad joints, caused by a simple gypsum board joints cracks. At this point, peel off the zipper, open the seam (gap width in the 2-5mm). With capped gypsum blockade, until the basic dry and then paste the white latex adhesive tape (Note: must be in the zipper and then brush again white latex glue), until the white latex thoroughly dry and then putty, polished, Paint.

- Q: Light steel keel is a flat ceiling or integrated ceiling?

- Light steel keel skeleton is widely used in the decoration of the ceiling can use light steel keel skeleton But in order to facilitate the construction, often the ceiling keel will be used to other materials or the use of other materials and light steel keel construction

- Q: Light steel keel gypsum board ceiling artificial materials about how much money a square meter

- If your area of woodworking workers daily wage does not exceed 200 yuan per square can float 8 yuan or so.

- Q: Home woodworking ceiling, with wood keel and light steel keel which cost-effective higher ah?

- To be honest, light steel keel cost-effective. This is also part of the progress of the times.

- Q: What is the keel of the aluminum veneer, or the angle welded frame?

- General buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM. Desheng Guangxing hope to help you.

- Q: Light steel keel ceiling boom and whether the strong electric lines can be common

- It is best not to put together. Because light steel keel rods are metal substances, there is a strong ability to conduct. If you wear a wire tube can share a pole.

Send your message to us

Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords