Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Weight PVC PU Conveyor Belt Wood Application

Description of PVC Conveyor Belt:

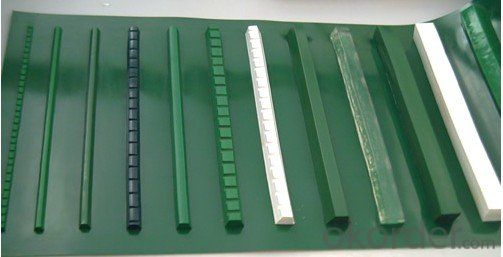

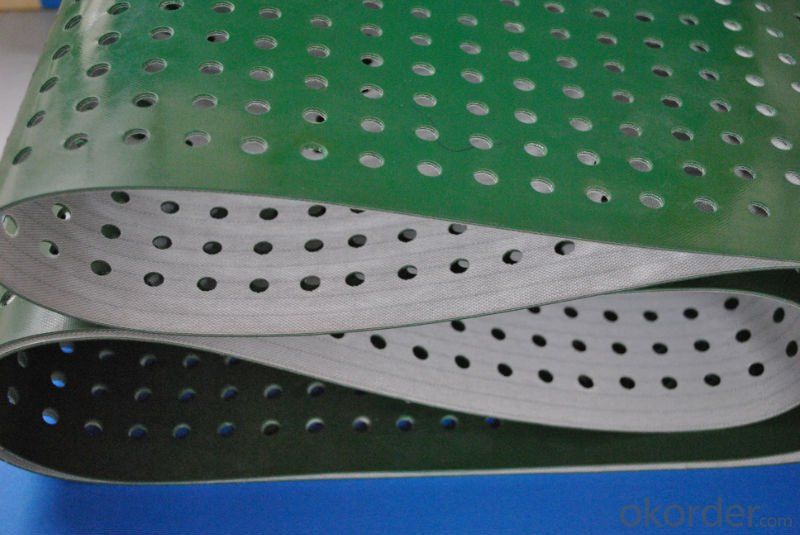

The wood processing belt that CNBM produce have the characterics of low elongation, pending, low nise, stable size, durable, wear-resisting.This kind of belt are used different material, decorative pattern and high strength of the fabric to increase stability and strength.Products can be widely used in plywood, fiberboard, composite board production line and all kinds of woodworking machinery equipment.

With advanced technology and equipments, we could offer an extensive line of light weight conveyor belting, now our belts are widely used in airports, postal automation, parcel handling, treadmills, packaging and wrapping, confectionery industry, food processing industry, paper printing industry and so on..

Feature of PVC Conveyor Belt:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Working temperature ranges from -10 to 80Deg.C

| code | Top cover | Bottom Cover | Thick | Characteristics | Fabrics | ||||

| Material | Colour | Surface | Material | Colour | Surface | mm | Plies | ||

| PVC conveyor belt | |||||||||

1/10 S/P W | PVC | White | Smooth | - | Natural | Fabric | 1.0 | Antistatic | 1 |

1/12 S/S BK | PVC | Black | Smooth | PVC | Black | Smooth | 1.2 | 1 | |

1/16 D/STF BK TM | PVC | Black | Diamond | - | Natural | Strong Fabric | 1.6 | Tread mill | 1 |

2/12 P/P W | Fabric | Natural | Fabric | Fabric | Natural | Fabric | 1.2 | Antistatic | 2 |

2/18 P/P W | Fabric | White | Fabric | - | Natural | Fabric | 1.8 | Antistatic | 2 |

2/20 D/P AG | PVC | Apple Green | Diamond | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/2O S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P PG | PVC | Petrol Green | Smooth | - | Natural | Fabric | 2.0 | No-antistic | 2 |

2/20 M/P BK | PVC | Black | Matt | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.0 | FDA | 2 |

2/20 S/P W | PVC | White | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/20 S/P BK | PVC | Black | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/25 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.5 | FDA | 2 |

2/30 S/FF PG | PVC | Petrol Green | Smooth | - | Natural | Flexible Fabric | 3.0 | Cold-Resistant | 2 |

2/30 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 3.0 | FDA | 2 |

2/30 S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

2/30 LR/SF AG | PVC | Apple Green | Longitudinal Lib | - | Natural | Silent Fabric | 3.0 | 2 | |

2/30 S/D W FDA | PVC | White | Smooth | PVC | White | Diamond | 3.0 | FDA | 2 |

2/30 S/D W | PVC | White | Smooth | PVC | White | Diamond | 3.0 | 2 | |

2/30 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 3.0 | Antistatic | 2 |

2/38 S/P W | PVC | White | Smooth | - | Natural | Fabric | 3.8 | 2 | |

2/46 TS/P AG | PVC | Apple Green | Saw Tooth | - | Natural | Fabric | 4.6 | Antistatic | 2 |

2/50 RT/P AG | PVC | Apple Green | Rough Top1 | - | Natural | Fabric | 5.0 | No-antistic | 2 |

3/30 C/C W | Cotton | Natural | Cotton | Cotton | Natural | Cotton | 3.0 | 2ply cotton 1ply fabric | 3 |

3/40 S/P TAN | PVC | TAN Colour | Smooth | - | Natural | Fabric | 4.0 | No-antistic | 3 |

3/50 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 5.0 | Antistatic | 3 |

3/40 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 4.0 | FDA | 3 |

| PU conveyor belt | |||||||||

1/08 S/P W U FDA | PU | White | Smooth | - | Natural | Impreg-nated | 0.8 | Antistatic | 1 |

2/15 M/P W U FDA | PU | White | Matt | - | Natural | Impreg-nated | 1.5 | Antistatic | 2 |

2/14 M/P PG U FDA | PU | Petrol Green | Matt | - | Natural | Impreg-nated | 1.4 | Antistatic | 2 |

2/21 S/P W U FDA | PU | White | Smooth | - | Natural | Fabric | 2.1 | Antistatic | 2 |

2/21 S/P W U KE | PU | White | Smooth | - | Natural | Fabric | 2.1 | Knife Edge Application | 2 |

2/30 S/P

W U FDA | PU | White | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

Pictures of PVC Conveyor Belt

Pls contact me freely if any inquiry or questions,thank you!

- Q: Are there formaldehyde in rubber products, too?

- 1, stimulation: mainly affect performance of formaldehyde for the stimulation of the skin and mucous membrane, formaldehyde is a protoplasmic poison, can bind with protein, when high concentrations of inhaled respiratory severe irritation and edema, eye irritation, headache.2, sensitization: skin direct contact with formaldehyde can cause allergic dermatitis, pigmentation and necrosis, inhalation of high concentrations of formaldehyde can cause bronchial asthma.3. Mutagenicity: high concentration formaldehyde is a genotoxic substance. Laboratory animals can cause nasopharyngeal tumors at high concentrations in the laboratory.

- Q: Process for producing rubber products

- In the production process of rubber products, the process of making various shapes and sizes is made by using a calender or an extruder, which is called forming. Forming methods are1. rolling formingThe utility model is suitable for making simple sheet and plate shaped articles. It is a method of pressing compound rubber into a certain shape and a certain size of film by calender. It is called calendering forming. Some rubber products, such as tires, adhesive tape, hose and other textile fiber materials, must be coated with a thin layer of glue on the fiber, also known as glue or glue, the process of gluing is generally completed on the calender. Fiber material needs drying and dipping drying before calendering. The purpose is to reduce moisture content of fiber material, avoid evaporation and foaming, and increase the temperature of fiber material, so as to ensure the quality of calendering process. Dipping is a necessary process before cementing. The purpose is to improve the bonding property of fiber and rubber.2. extrusion moldingFor more complex rubber products, such as tyres, tread, hose, and wire surface coating, shall be made by extrusion molding. It is a method of continuous molding with a certain plastic compound into the extruder's hopper, the extrusion of the screw under the internal screw, and through a variety of dies, also known as the templates. Before extrusion, the material must be preheated to make the material soft and easy to extrude so as to obtain a smooth and accurate rubber product.3. moldingIt can also be used to make some rubber products with complex shapes, such as leather bowl and sealing ring. The rubber material is placed in the mold and shaped by heating.

- Q: In addition to the smell of rubber?

- Soil recruit: 300 grams of black tea, hot tea, two washbasin water, into the living room, and window ventilation, 48 hours, indoor formaldehyde content will fall by more than 90%, the pungent odor is basically eliminated.

- Q: How can I make rubber products brighter?

- The release agent shall have greater tensile strength so that it is not easy to be polished when it is in contact with the molding resin. This is especially true when there are frosted mineral fillers or glass fiber reinforcements in the resins. The release agent shall be chemically resistant so as not to be dissolved in contact with the chemical constituents of different resins (especially styrene and amines). Release agent should also have heat and stress properties, not easy to decompose or wear; release agent should be bonded to the mold, and not transferred to the processed parts, so as not to interfere with painting or other two processing operations.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 703, temperature range of -50-150, water resistance, salt water effect is good, mainly used for cable potting, instrument waterproof seal, watchcase bonding;

- Q: How to make white rubber products do not yellow or delay yellowing time?

- Then aging is divided into thermal aging, oxygen aging, ozone (electrostatic belongs to ozone, because static electricity produces ozone). Gas corrosion aging, heavy metals, oxidation aging. Reaction aging. UV aging and so on.

- Q: What's rubber skin?

- The general rubber has good comprehensive properties and is widely used. The main contents are as follows: natural rubber. From the latex of the Hevea tree, the basic chemical composition is cis polyisoprene. Good elasticity, high strength and good comprehensive performance. Isoprene rubber. The full name is cis -1, 4- polyisoprene rubber, a high CIS synthetic rubber made from isoprene, because of its structure and properties similar to natural rubber, it is also called synthetic natural rubber. Styrene butadiene rubber. Referred to as SBR, made by copolymerization of butadiene and styrene. According to the production method, emulsion polymerization, styrene butadiene rubber and solution polymerized styrene butadiene rubber are divided into emulsion polymerization. Its comprehensive properties and chemical stability are good. The br. The full name is cis -1, 4- polybutadiene rubber, referred to as BR, made from butadiene polymerization. And the other than universal rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and excellent elasticity, dynamic load, less heat, good aging resistance, easy and natural rubber, chloroprene rubber, nitrile rubber and etc..

- Q: What are the reasons for rubber cracking after shock absorption of rubber products?

- The rubber itself is poor in tearing and its products are overloaded.

- Q: What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

- Q: How is the temperature range of rubber determined?

- Rubber is based on rubber molecular structure and molecular weight as well as microscopic view to determine temperature range!

Send your message to us

Light Weight PVC PU Conveyor Belt Wood Application

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords