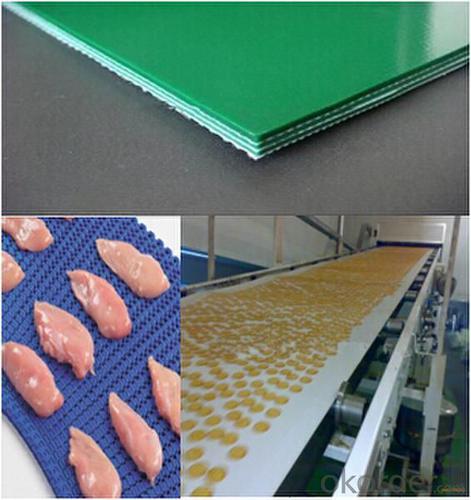

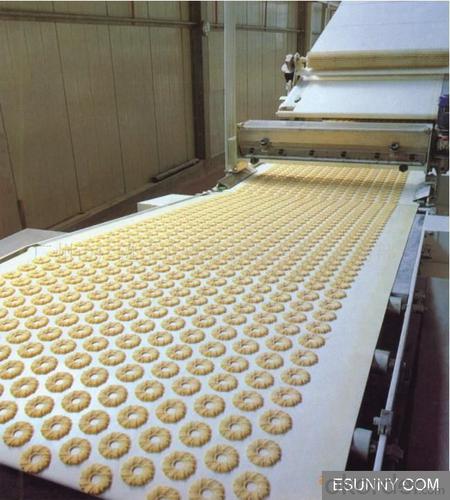

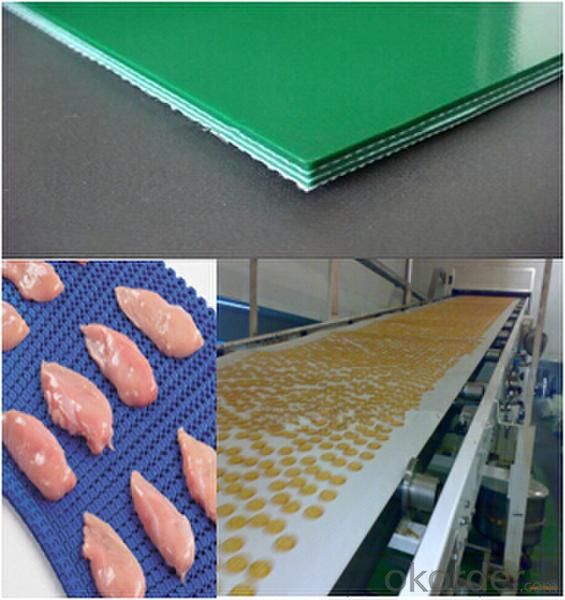

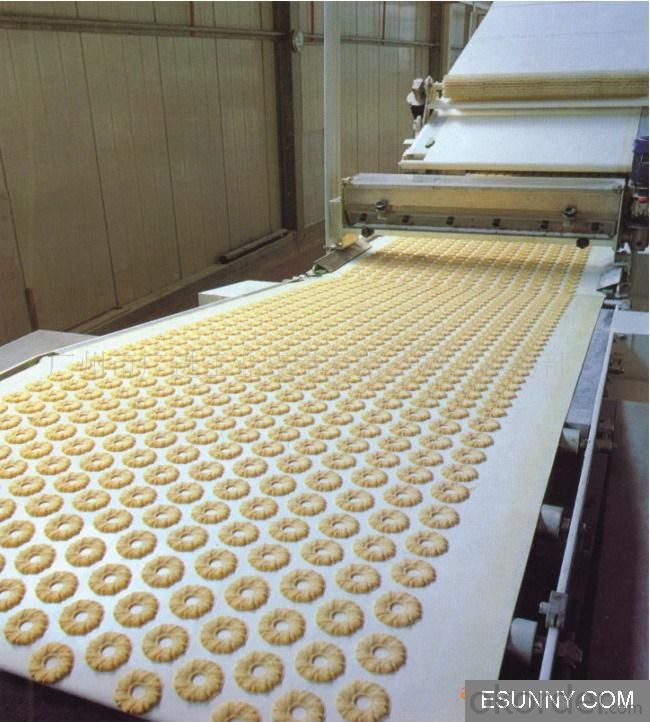

PVC Conveyor Belt Light Duty Food Grade White Food Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt Light Duty Food Grade

Applications & features:

Ø Especially suitable for material conveying at inflammable of underground coal mines.

Ø The fabric is high in strength , with low elongation, light carcass, shock resistant, anti-tear and good in trough ability.

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Various surfaces with high, medium, and low coefficient friction

Dimensional stability

Less noise

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

- Q: Why is rubber resistant to compression and wear better than metal?

- The rubber bushing is made of metal and has a flexible connection. The sheath is made of rubber

- Q: What kinds of rubber are edible grade safety rubber?

- Natural latex sterilized as condoms, natural rubber or butyl glue used in oral liquid or infusion bottle glue plug, silica gel is most commonly used in the body false organs, mainly stable, no bacteria and so on.

- Q: What are the common rubber products, please tell me

- A high molecular compound with an elastic, insulating, impermeable, impermeable gas. It is divided into two kinds: natural rubber and synthetic rubber. Rubber products are widely used in industryIndustry or life in all its aspects.

- Q: In addition to the smell of rubber?

- Soil recruit: 300 grams of black tea, hot tea, two washbasin water, into the living room, and window ventilation, 48 hours, indoor formaldehyde content will fall by more than 90%, the pungent odor is basically eliminated.

- Q: Rubber rolling process for making rubber products

- Rubber mastication is force, heat, oxygen or adding some chemical agents and other methods should be made by mechanical, rubber transition from elastic state for strengthening soft, easy processing of plastic process.Rubber mastication is designed to reduce its elasticity, increase the plasticity, and obtain adequate liquidity, mixing, rolling, extrusion, molding, curing and glue manufacturing, sponge and other manufacturing process to meet the requirements of.Mastering proper plasticity of plastic is essential to the processing of rubber products and the quality of finished products. The plastic degree should be reduced as much as possible in order to meet the requirements of processing technology. With the appearance of constant viscosity rubber and low viscosity rubber, some rubber is no longer need to be refined and mixed directly.

- Q: Is polyurethane and polyurethane rubber one thing?

- Plastics, such as Taiwan and Hongkong, are commonly referred to as plastics, so there is little point in distinguishing between plastics and rubber. From a theoretical point of view, the distinction between plastic and rubber is generally based on whether the glass transition temperature (Tg) of the material is above normal or below normal. Polymers that are generally less than Tg at normal temperature are called plastics (e.g., polyethylene, Tg, -78 degrees), while polymers with Tg temperatures higher than normal are called rubber.

- Q: How to distinguish between silicone hose and rubber tube by appearance?

- Smell, silicone no flavor, rubber flavor, silicone general flexibility better, rubber mechanical better

- Q: What about the smell of smoked rubber products?

- Rubber deodorant both rubber itself, also want to consider a variety of additives such as odor curing agents released, in addition to the use of rubber ingredients to improve rubber products and improve the level of environmental protection, rubber production environment, is of great help for the comprehensive utilization of recycled rubber resources. A form of powder or liquid used in rubber, usually based on odor and odor characteristics.

- Q: Will rubber products fade?

- It looks like, especially if it's outdoors for a long time

- Q: What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The main use of natural rubber natural rubber because of its insulation, plasticity, water vapor barrier, tensile and wear characteristics of strong elasticity and good, widely used in industry, agriculture, national defense, traffic, transportation, machinery manufacturing, medical and health fields and daily life, such as transportation with the tire industry; with the transport belt, transmission belt, sealing rings; medical gloves, transfusion tube; used in the daily life of the shoes, raincoats, warm water bag are rubber as the main raw materials manufacturing, defense on the use of aircraft, artillery, tanks, and cutting-edge technology in the field of rockets, satellites, spacecraft, space shuttle requires a large amount of rubber parts.

Send your message to us

PVC Conveyor Belt Light Duty Food Grade White Food Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords