Light Duty PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Duty PVC Conveyor Belt with Punching Hole

Descriptions of PVC Conveyor Belt

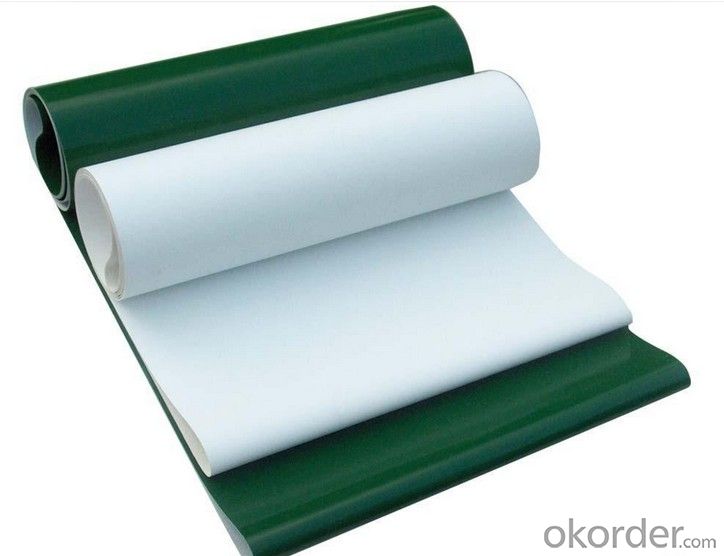

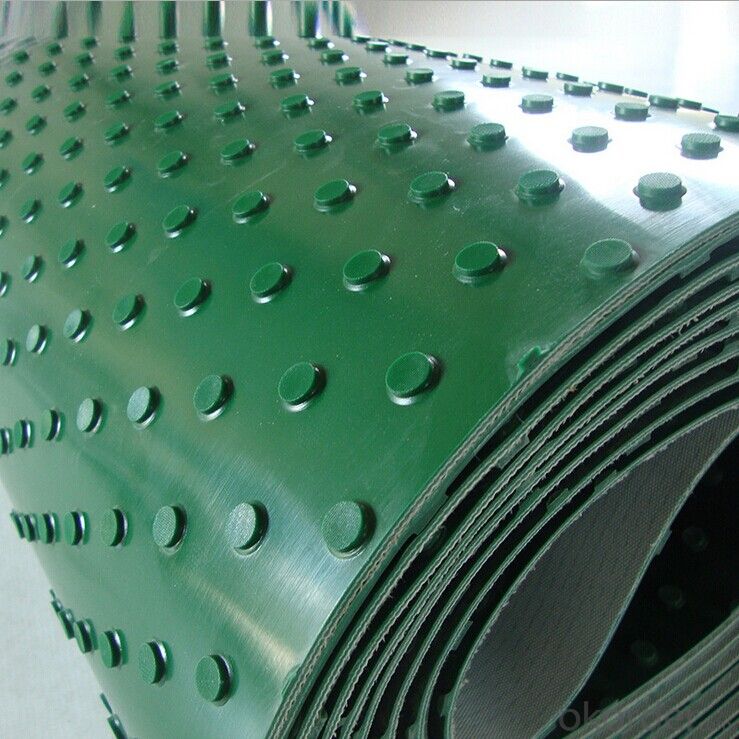

PVC Conveyor Belt with Punching Hole

Characters:

1.High tensile strength, well circumnutate properties, light, thin, pliable but strong, oil resistant,non-toxicity,hygiene,easy clear.

2. Abrasion resistance,anti physical aging.

3. Acid/alkali resistant,cutting resistant,small turning radius.

4. It can be added V-type conducting bar underside and conducting bar or baffle on the surface.

5. Colors:white and green,etc.

6.Different thickness and width.

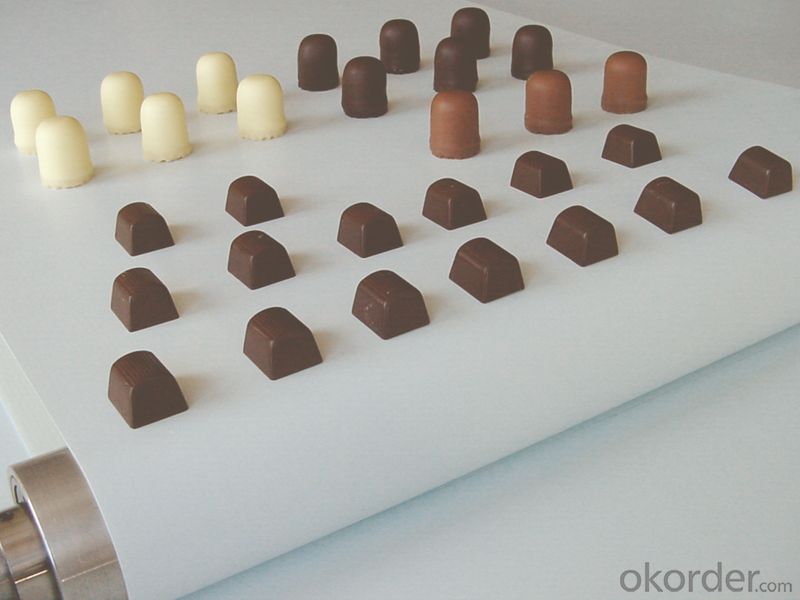

7.Appearance:high gross surface,matte,mainly used in food industry.

PVC/PU CONVEYOR BELT APPLICATION AREAS

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How to identify the tire rubber is raw or cooked

- Rubber molding, after pressing, the elastic body is within the cohesion can not be eliminated, the molding die, often have a very unstable contraction (rubber shrinkage due to rubber vary), required after a period of time, and can be stable. Therefore, when a rubber product design at the beginning, regardless of formula or mold, it is necessary to carefully calculate the coordination, if not, it is easy to produce product size instability, resulting in lower quality products.

- Q:What's the difference between natural rubber and three yuan ethylene propylene rubber?

- The dielectric properties of natural rubber are a nonpolar substance that is soluble in non-polar solvents and non-polar oils. Natural rubber is not resistant to cyclohexane, gasoline, benzene and other media, non vulcanized rubber can be dissolved in the above medium, vulcanized rubber swelling. Natural rubber insoluble in polar acetone, ethanol, more insoluble in water, resistant to 10% hydrofluoric acid, 20% hydrochloric acid, 30% sulfuric acid, 50% sodium hydroxide and so on.

- Q:Explain why butyl rubber is more resistant to oxidation and aging than other elastomers, such as natural rubber

- Ding Ji rubber (abbreviation: IIR English Name: Isobutylene-isoprene Rubber)Ding Ji rubber is an elastomer made from a small amount of isoprene (butadiene) copolymerized with isobutene with a high degree of saturation. Generally do not need refined refining, pay attention not toBlends with unsaturated rubber with low degree of unsaturation. Use super accelerators and less sulfur or cure with resin. Due to the slow vulcanization rate of ordinary butyl rubber and high unsaturated rubberIts poor compatibility, self adhesion and co adhesion were not good, and then it was modified by halogenation, which improved its curing rate and compatibility with other high unsaturated rubber

- Q:What are the causes of the rubber products breach?

- First: the use of rubber joints in the process of linking the length is not enough to force beyond the length of the link, the expansion of the scope of contraction may also splitSecond: rubber joints, the strength of the link is relatively low, then if the adhesive method is not accurate, the strength of the joint will be lower, there may be crackingThird: rubber joints after installation, in other places free here beyond the extension range of pipe strap, there may be cracking.Fourth: rubber joints in the outdoor adverse weather, explosion, sun, etc., lower than the use of temperature may also crack.Fifth: in the process of production of vulcanized rubber joint used in rubber function is not good or has been since sulfur failure, excessive grinding, wire rope and other parts of the rust, the joint strength will be greatly reduced, when in use, will likely easily disconnect joint phenomenon

- Q:What about the smell of smoked rubber products?

- The curing agent and accelerator taste, rubber itself is tasteless, sulfur curing agent debris less is better, if no sulfur, with peroxide. Oil will also produce a flavor, rubber Odor Remover can be removed, in fact, that is, some spices, oh!Now there is a special rubber deodorant in the market, you may as well try.Can buy some activated carbon in the box, the cost is not high, but also long lasting odor.

- Q:What are the hazards of rubber accelerators?

- I have been engaged in the rubber industry for many years. I personally think that the accelerator has no harm to people. Wearing gloves, masks and protective measures during operation will not be harmful.

- Q:How can rubber be preserved without decay?

- Early rubber was made from latex of rubber trees, rubber grass and other materials made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q:What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- Generally, aging and dissolution occur. If you want to make the structure, you can choose XF POM C13031 Ticona of the company. This is the company specializing in the development of temperature resistance, oil (especially gasoline, diesel) products.

- Q:What solvent is used to clear the melted rubber layer?

- Dry glue in water does not exceed 1%, in the process can be volatile, but the moisture content is too long, will not only make the rubber easy to mildew during storage, but also the impact of rubber processing, such as mixing with the agent is easy to agglomerate; easy to blister calendering and extrusion process, the bubble or a sponge the curing process etc..

- Q:How to remove the rubber front?

- Conversely, the product is small, large in quantity, or where it is hard to repair, so you can consider machine trimming.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty PVC Conveyor Belt with Punching Hole

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords