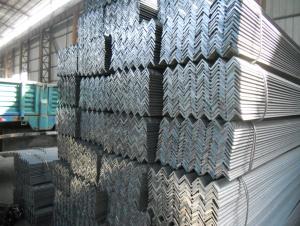

JIS Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Angle Steelare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2 Can stainless steel rust?

A2 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the load-bearing capacities of different sizes and types of steel angles?

- The load-bearing capacities of different sizes and types of steel angles vary depending on factors such as the material grade, dimensions, and specific design requirements. It is essential to consult engineering tables or design codes, as they provide detailed information on load-bearing capacities for different steel angles.

- Q: What are the different types of steel angles used in construction?

- There are several types of steel angles commonly used in construction, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. These angles are used to provide structural support, reinforcement, and stability in various building applications.

- Q: What are the common standards and specifications for steel angles?

- The common standards and specifications for steel angles vary depending on the application and the country in which they are being used. However, some widely recognized standards and specifications include: 1. ASTM A36/A36M: This is a standard specification for carbon structural steel, including steel angles. It covers shapes such as angles, channels, and beams, and specifies the chemical composition, mechanical properties, and other relevant requirements. 2. ASTM A529/A529M: This specification covers high-strength carbon-manganese steel shapes, including angles, used in construction. It provides requirements for chemical composition, mechanical properties, and other important characteristics. 3. ASTM A572/A572M: This specification covers high-strength low-alloy structural steel shapes, including angles. It specifies the chemical composition, mechanical properties, and other relevant requirements for these shapes used in construction applications. 4. EN 10056: This European standard specifies the tolerances on shape, dimensions, and mass of hot-rolled structural steel equal and unequal angles. It provides requirements for the chemical composition, mechanical properties, and other characteristics of steel angles. 5. JIS G3192: This Japanese industrial standard specifies the dimensions, mass, and tolerances for hot-rolled steel sections, including angles. It sets forth the requirements for chemical composition, mechanical properties, and other relevant specifications. These are just a few examples of the commonly used standards and specifications for steel angles. It is important to consult the specific regulations and standards applicable to the region and application in order to ensure compliance and meet the desired requirements.

- Q: What are the different types of steel angles used in shipbuilding?

- Various structural purposes in shipbuilding commonly utilize several types of steel angles. These angles are typically crafted from high-strength steel and are intended to confer strength and stability to the ship's structure. Presented below are different steel angle varieties utilized in shipbuilding: 1. Bulb Angles: Specifically designed for ship hull construction, these angles possess a bulbous shape on one side. This unique shape aids in load distribution while adding further strength and stability to the hull structure. 2. L-Shaped Angles: Also known as unequal angles, L-shaped angles find extensive usage in shipbuilding for framing and bracing requirements. With one leg longer than the other, these angles accommodate various applications necessitating varying lengths. 3. Equal Angles: Commonly referred to as L-sections, equal angles consist of two legs of identical length. Shipbuilding extensively employs them for framing and supporting structures, as they confer uniform strength. Their versatility extends to applications such as bulkhead framing and deck support. 4. Flat Bars: While technically not angles, flat bars are frequently employed in shipbuilding for comparable purposes. These bars possess a rectangular cross-section and are primarily used for reinforcement, framing, and connecting different structural components. 5. T-Sections: T-sections, or T-angles, feature a T-shaped cross-section and serve in shipbuilding for structural framing, reinforcement, and component connection. The vertical leg of the T-section imparts additional strength and stability to the structure. 6. Z-Sections: Z-sections, or Z-angles, possess a Z-shaped cross-section and fulfill various shipbuilding purposes such as framing, bracing, and structural support. These angles offer excellent load-bearing capacity and are frequently utilized when maximum strength is required. Ultimately, the selection of steel angles in shipbuilding hinges upon the specific requirements of the structure, encompassing load-bearing capacity, structural design, and intended purpose. The aforementioned steel angle types provide a vast array of options to cater to the diverse demands of ship construction.

- Q: How do steel angles contribute to the overall sustainability of a building?

- Steel angles contribute to the overall sustainability of a building in several ways. Firstly, steel angles are made from recycled materials, making them a sustainable option for construction. Steel is one of the most recycled materials in the world, with a high recycling rate, reducing the need for virgin resources and minimizing the environmental impact of extraction and production. Additionally, steel angles offer structural efficiency, which means that they can support larger loads with less material compared to other building materials. This efficiency reduces the amount of steel required in construction, minimizing the carbon footprint associated with steel production and transportation. Furthermore, steel angles are highly durable and long-lasting. They have a high resistance to corrosion, fire, and pests, which reduces the maintenance and replacement needs over the building's lifespan. This durability translates into reduced waste generation and lower life-cycle costs, making the building more sustainable in the long run. Moreover, steel angles are versatile and can be easily reused or repurposed. If a building needs to be renovated or demolished, the steel angles can be salvaged and reused in other construction projects. This promotes a circular economy approach and minimizes waste generation, contributing to the overall sustainability of the construction industry. Lastly, steel angles have excellent thermal properties, which can enhance the energy efficiency of a building. They can be used as part of the building envelope, helping to reduce energy consumption for heating and cooling. By improving the insulation and airtightness of a building, steel angles contribute to lower energy demand and reduced greenhouse gas emissions. In conclusion, steel angles contribute to the overall sustainability of a building through their recycled content, structural efficiency, durability, recyclability, and energy-saving properties. By choosing steel angles in construction, we can promote resource conservation, reduce waste generation, and minimize the environmental impact of the built environment.

- Q: Can steel angles be used for electrical conduits?

- No, steel angles cannot be used for electrical conduits as they are not designed or suitable for carrying electrical wiring. Electrical conduits are typically made of materials such as PVC, steel, or aluminum that are specifically designed to safely enclose and protect electrical wires.

- Q: What is the purpose of using steel angles in construction?

- Steel angles are commonly used in construction for several purposes. The primary purpose of using steel angles is to provide structural support and stability to various components of a building or structure. These angles are often used to reinforce corners, edges, and joints, adding strength and rigidity to the overall structure. Additionally, steel angles are used to distribute and transfer loads or forces within the construction. They help to evenly distribute the weight and stress across different parts of the structure, preventing any concentrated points of weakness. Moreover, steel angles are versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, allowing for seamless integration into a wide range of construction projects. Furthermore, steel angles offer excellent durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. They can withstand heavy loads, extreme weather conditions, and provide long-lasting support to the structure. In summary, the purpose of using steel angles in construction is to enhance the structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: Can steel angles be used in the construction of railway bridges?

- Certainly! Railway bridges can indeed incorporate steel angles into their construction. Steel angles possess great versatility as structural elements and can serve multiple purposes, including bridge construction. They are frequently employed in the manufacturing of bridge girders, braces, and supports. Thanks to their exceptional strength and ability to bear heavy loads, steel angles are ideal for railway bridges that demand robust structural integrity and longevity. Moreover, the ease with which steel angles can be welded, bolted, or riveted together facilitates efficient and cost-effective construction methods. Ultimately, steel angles represent a viable and frequently utilized component in the construction of railway bridges.

- Q: How do steel angles resist bending or deflection?

- Steel angles resist bending or deflection due to their shape and material properties. The design of steel angles, with their L-shaped cross-section, provides structural stability and strength, making them highly resistant to bending or deflection under load. The L-shape of steel angles creates two perpendicular legs, which distribute the applied load more efficiently compared to other shapes. This distribution of load allows the angles to resist bending forces, preventing them from deforming or deflecting significantly. The longer leg of the angle provides greater leverage and stiffness, enhancing its resistance to bending. Moreover, steel itself is a strong and rigid material, known for its high tensile and compressive strength. Steel angles are typically made from hot-rolled steel, which undergoes a process that further improves its structural properties. The combination of the L-shape design and the inherent strength of steel enables steel angles to withstand bending forces without significant deflection. Additionally, steel angles can be reinforced through various methods such as welding or bolting to increase their resistance to bending or deflection. Reinforcements add additional strength and stiffness to the angles, making them even more robust and capable of withstanding higher loads. In summary, steel angles resist bending or deflection due to their L-shape design, the inherent strength of steel, and possible reinforcements. These factors work together to provide structural stability and prevent excessive deformation, making steel angles a reliable choice for various construction and engineering applications.

- Q: How do you calculate the weight-bearing capacity of a steel angle?

- To calculate the weight-bearing capacity of a steel angle, you need to consider its dimensions, material properties, and loading conditions. The weight-bearing capacity can be calculated using engineering formulas and techniques such as the Euler formula or the AISC Manual. These calculations take into account factors like the cross-sectional area, moment of inertia, and the applied loads to determine the maximum load the steel angle can support without failure.

Send your message to us

JIS Standard High Quality Angle Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords