Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Processing: Fermenting Equipment, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: fermentation tank, KB-005

Processing Types: Alcohol

Certification: B&V; CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Specifications

1. interior: mirror polished, exterior: semi-luster for main body

2. material: SUS304 or 316L

3. top dish head, conical bottom

| Industrial beer brewing equipment | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for beer fermentation |

| Material | 1.SUS304, 316L |

| 2.jacket: dimple jacket | |

| 3.insulation layer: PU | |

| 4.as to the thickness, we can make it according to your requirement. | |

| Configuration | safty valve, CIP spraying ball and pipe at the side of the tank, outlet with valve and racking arm as your requirement, temperature gauge and sample valve |

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 10,000L and even larger. |

| 2.PU insulation is adopted, jacket will be dimple jacket | |

| 3.interior surface is 3Afinish and exterior is 2B finish | |

| 4.we also can equip you with a cooling system as your requirement. | |

| 5.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroad |

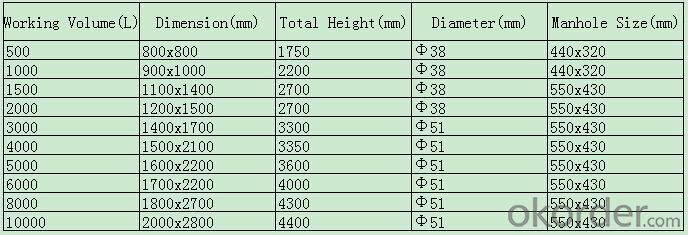

Technical Data:

- Q: I have a Vokera Compact 29HE boiler in a house with 6 people. (rated B). Currently my combined Gas and Electricity bills are ?2600 per year - just over half being gas. Will changing my boiler greatly reduce this cost? I don't think my house is particularly warm in the winter, i have the heating on a timer in the morning and evening only so the weekend in the day its freezing. Any ideas/suggestions would be most welcome.

- The utility bills don't make any sense unless you reference them to a location. Nome, Alaska vs. Sao Paulo, Brazil, for example. If your current boiler is 80% efficiency and you get one that's 90% efficient, you can expect to save 10% of your heating costs per year. If that happens to be 130 Pounds? It will take 20 years just to recover the cost of a new boiler. The money would be better spent on reducing your energy losses, such as better windows and doors, more insulation in the attic, and other things that an energy audit can find. Make sure you get a blower door test and an infrared scan of the house. Then you can really save some energy, possibly in the 20%-30% range.

- Q: i repaired a broken heating water pipe. how do i bleed my oil fired system it is base board heat

- there are bleeder screws on the base boards

- Q: I have a hydronic heating system and have recently bled my radiators (because there was a lot of clanging recently when the boiler turned on, so I was under the impression that that was because of a build-up of air in the pipes) So, I bled the radiators, and ever since then my boiler has not turned on. I also have lost all pressure (gauge reads zero). Wondering if the loss of pressure is a result of bleeding, and if so, how to I get back the pressure.

- it sounds like you dont have enough waterin the system. add water to the boiler to get upto 20 ponds of pressure then if you need to bleed the radiators you need to maintain 15 to 20 pounds of pressure

- Q: The development of the boiler

- With the passage of time, environmental protection and energy conservation has become an important direction of China's power industry structural adjustment, thermal power industry in the "big pressure on the small" policy-oriented to actively promote the industrial structure optimization and upgrading, shut down a large number of low energy efficiency, heavy pollution,

- Q: We have an offer on our home. Boiler has a crack in the chamber discovered at inspection. We were not there. We moved out of state. We got an estimate from our fuel/heating company for a fair amount. We're getting a break since we have worked with them for many years. They will put in a comparable new boiler. The house is in the Hudson Valley NY. Temps are near freezing already. We want to get this done now so as not to have pipes freeze. Potential buyers want to know how much the boiler will cost us. They want to upgrade through their company! This will put a strain on us financially. Their company may not give us the same deal for the boiler we were going to put in. Also we will have to wait to do this till after contracts or maybe even till closing. They will accept allowance or lower offer.Our company was going to allow us to pay this off by financing it for a year with half down. Buyers made offer on house with old boiler. They don't need to know what we pay for boiler?!

- No, they cannot hold out for an upgrade. The buyer's have a right to get the boiler in working condition, and you have made arrangements to do that. Banks will not loan on a home without a working heating system. You don't have a choice but to fix it, and you AGREED to an inspection, and just because you vacated the home isn't their problem. How do they know you were not aware it was cracked when you put it on the market? How are they, as lay people, supposed to know the heating system isn't working during the summer? You CAN (if you are feeling generous), allow the buyer's to do the upgrade and you only pay or what YOUR company quoted you...that way they get the system they want and you are not out extra money. However, if I were your Realtor, I would advise AGAINST doing that. A closing can fall through, and you can get stuck with the bill. There is another issue: If I were representing the BUYERS, I would advise to them to NOT accept your financing the system that is attached to the house. If you default, that gives the company and automatic right to file a UCC lien against the PROPERTY, and leaves the buyers holding the bag. In fact, there is a document that you have to sign at closing that you haven't had ANY work done on the house that isn't paid for in full...if you lie, then that is a material misrepresentation. You need to pay it out of your proceeds, up front.

- Q: On the hot water heating pipe above my boiler, there is a green elbow-like joint with a small valve on top. I've been having clanking and swishing water sounds in my baseboard, so I'm guessing there's a bunch of air in my baseboard lines.I've tried to bleed the lines from the baseboard valves, but I never get any air coming out, just trickling water. My uncle says it may have to do with the valve over the boiler. He says you are supposed to leave it a little loose to allow air to escape. When I went down there, it was as tight as it could go. It is safe to loosen this a bit and leave it like that?Also, could the reason the air wasn't bleeding out was that this valve was tight? Does it have to be loose in order to bleed the upstairs lines?

- don't mess with valves unless u know what your doing,could be very very BAD!!! sounds like u may need more water in your boiler,,,find a press gauge on your boiler,,1 lb of water press will go up 27 inches from the press gauge so figure how hi up the highest radiant is and do the math,,add h20 and keep press up and bleed till no air,this is assuming u have a hot h20 boiler and not steam..a few pounds over the highest radiant is recommended

- Q: I worked with a plumbing contractor to put a new steam boiler in my house. As I know, steam boilers need to be sized correctly I verbally verified the sizing with him. Unfortunately, on the install date I could not be home because I just started a new job. He installed a boiler far bigger than I discussed. As well, the boiler documentation states that the boiler will not be warrantied if mis-sized. However, the contract did not state the size. I have withheld payment but the contractor is threatening a lien. Am I screwed?

- Are you sure it’s a steam boiler? They’re pretty rare these days. At any rate, oversized units are not as bad as undersized units. They will get the steam to your radiators faster and cycle more often with a lower duty rate, not necessarily bad. Check your sizing with the manufacturer to ensure you are covered by their warranty. Your contract should have specified what you were buying. Check with your local Consumer Protection Agency or Better Business Bureau for potential recourse. You may have paid for a larger unit than you bargained for. Don’t worry about a lien unless you plan on selling in the near future. Construction liens are a safety mechanism for contractors and sub-contractors to make sure they get paid if you sell the house. They usually carry a time limit or the contractor has a time limit to remove the lien after the matter is resolved. Either way, check to make sure the lien is removed when all is resolved (don’t take their word on it).

- Q: I have yet to see a Boiler match, is there any PPV that I could buy to see one?

- Summer Slam 1996 Mankind v. Undertaker Backlash 1999 Mankind v. Big Show

- Q: I have a boiler in my room, and i've put put fridge magnets on it to make it look a bit more cool. But i dont if it is safe or if it will set fire.

- I hope that you do not have a gas or oil fired boiler in your room, where you sleep. This is very dangerous and potentialy fatal if carbon monoxide poisoning occurs. Magnets are secondary to the fact that the boiler is in your room. I would not put anything on the boiler. Please let me know if the boiler is in your room where you sleep and what kind of boiler it is. Please let me know how large the room is and what kind of ventilation exists.

Send your message to us

Industrial Beer Brewing Equipment for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches