4x Sheets of Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Industrial Aluminium Profile 6000 Series Description:

Industrial Aluminium Profile 6000 Series (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Industrial Aluminium Profile 6000 Series:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

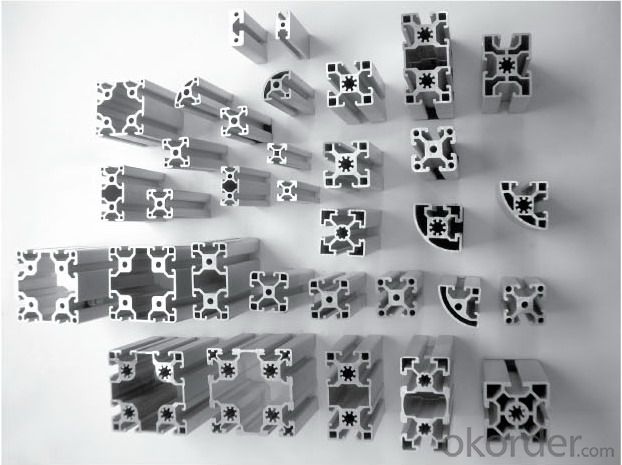

3.Industrial Aluminium Profile 6000 Series Images:

4.Industrial Aluminium Profile 6000 SeriesSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but generally ranges from 20,000 to 45,000 pounds per square inch (psi).

- Q: Is it possible to utilize aluminum sheets for crafting distinctive architectural structures?

- <p>Yes, aluminum sheets can be used to create unique architectural designs. Known for their strength, durability, and lightweight properties, aluminum sheets are ideal for various architectural applications. They can be easily shaped and cut to fit specific design requirements, offering flexibility in design and construction. Additionally, aluminum's resistance to corrosion and weathering makes it a sustainable choice for long-lasting structures. Architects often use aluminum for facades, roofing, and other exterior elements due to its modern aesthetic and low maintenance needs.</p>

- Q: Can aluminum plate resist acid and alkali?

- Acid base corrosion aluminum alloy, corrosion resistance, but nothing is absolute, even if the steel plate in the long-term corrosion of acid and alkali will also have problems

- Q: What are the different surface treatments available for aluminum sheet?

- There are several surface treatments available for aluminum sheet, including anodizing, powder coating, painting, and polishing. Anodizing provides a durable and corrosion-resistant finish, while powder coating offers a wide range of colors and enhanced durability. Painting allows for customization with various finishes and colors, while polishing provides a shiny and reflective surface. Each treatment option offers different aesthetic and functional benefits, depending on the specific requirements and desired outcome.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- Hardwood Refinishing low as $1per square foot #2 Common Red Oak Low as $4.45 per square foot, and finished! Brazilian Cherry starting at $7.95 per square foot, and finished (all sizes!) 608-728-2378

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only the zinc sheet reacts after adding concentrated nitric acid in drops ,zinc is amphoteric.

- Q: What is the thickness range available for 101 aluminum sheets?

- The thickness range available for 101 aluminum sheets typically varies from 0.016 inches (0.4 mm) to 0.25 inches (6.35 mm).

- Q: How are aluminum sheets cut or shaped?

- Depending on the desired outcome, various methods can be employed to cut or shape aluminum sheets. One commonly used technique involves the utilization of a saw, such as a circular saw or a bandsaw, equipped with a carbide-tipped blade specially designed for cutting metal. This allows for the creation of straight cuts and can be employed for both thin and thick aluminum sheets. Another approach entails the use of a shear, which is a machine equipped with sharp blades to effectively cut the aluminum sheet. Shearing is particularly advantageous when it comes to swiftly and efficiently cutting straight lines, especially for thinner sheets. For more intricate shapes or curves, aluminum sheets can be cut using either a water jet cutter or a laser cutter. Water jet cutting involves the usage of a high-pressure jet of water mixed with an abrasive substance to effectively cut through the sheet. On the other hand, laser cutting employs a focused laser beam to melt or vaporize the aluminum, resulting in precise and intricate cuts. In addition to cutting, aluminum sheets can also be shaped through processes like bending, rolling, or stamping. Bending necessitates the use of a press brake to bend the sheet into the desired angle or shape. Conversely, rolling involves employing a rolling machine to gradually shape the sheet into curves or cylinders. Lastly, stamping encompasses pressing the sheet against a die to create specific shapes or patterns. Ultimately, the choice of method for cutting or shaping aluminum sheets depends on factors such as the sheet's thickness, the desired outcome, and the availability of equipment.

- Q: why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

Send your message to us

4x Sheets of Industrial Aluminium Profile 6000 Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords