HZS100 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HZN/S Series Mobile Concrete Batching Plants are the result of advanced technology and engineering skills. They are new generation Batching Plants, the fruits of extensive R&D work, experience and accurate production facilities. This key concrete equipment is commonly used in large and medium-sized construction projects that need frequent site relocations, such as hydropower stations, roads, ports and so forth.

HZN/S Series Mobile Concrete Batching Plants can go thousands of kilometres on its own axle with a single towing vehicle for instance a trailer. Comparing other concrete batching plants, its advantages include:

☆ Compact design

☆ Easy installation and start-up

☆ Less foundation costs

☆ Fully automatic robust control system

☆ Reliable units (Siemens, WAM,Telemecanique, Beckhoff, Jotun, Pirelli etc.)

☆ Technologic and high quality production

PRODUCT DETAILS

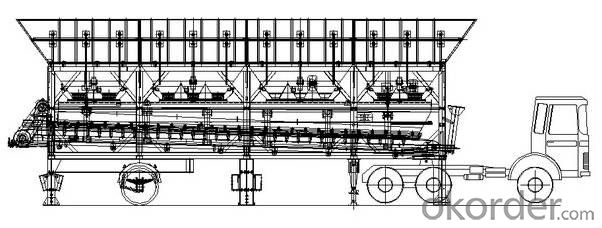

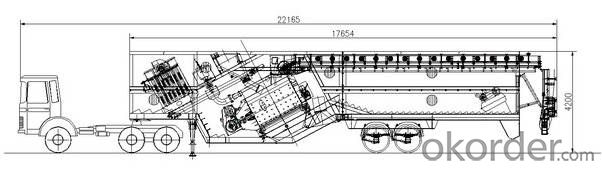

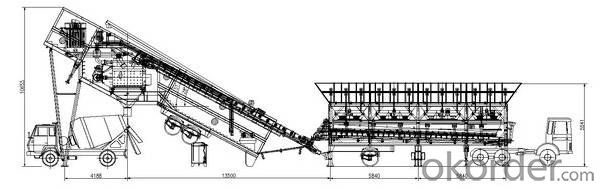

1. The aggregate weighing and conveying system, water supplying and additive agent supplying systems, weighing systems, mixing system, electrical control system and pneumatic system are fitted in one trailer.

2. Adopting module structure, designed as per the loading of standard container. All modules are in one trailing unit, it is easy for installation and disassembly and convenient for relocation.

3. Twin-shaft mixing host gives good product quality and high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic concrete and other types of concrete.

With discharge height at 3.8 m, it can work with any truck mixers.

4. It can store two or four types of aggregates at the same time and also with two cement silos and their respective screw conveyors;

5. All weight elements and control elements of weight system are from international well-known brands, controlled by computer, guaranteeing completely reliable and accurate weighing in rough conditions.

6. Platform or ladders equipped to each part needing maintenance and repairing. Good for maintenance.

7. The whole systemic computerized with dynamic panel display, to show clearly of the status of each component. Visualized monitor interface provides clear and real-time conditions of the site work. The plant operation data can be saved and printed out.

8. Electrical control system from international famous brands functions stably and powerfully. Automatic detection of abnormal working condition makes it easy for maintenance and trouble shooting.

9. It can be operated automatically or manually, and it is easy to switch between different operation modes.

SPECIFICATIONS

Model | HZS100 | |

Output (m3/h) | 100 | |

Mixer | Model | JS2000 |

Mixing Power (kW) | 2×37 | |

Discharging Volume (m3)) | 20 | |

Aggregate Size (Gravel/Pebble) (mm) | ≤60/80 | |

Aggregate Dosing Tank Capacity (m3) | 8 | |

Hoisting Motor Power (kW) | 30 | |

Weighing Range and Accuracy | Aggregate (Kg) | 3000±2% |

Cement (Kg) | 800±1% | |

Fly Ash (Kg) | 400±1% | |

Water (Kg) | 400±1% | |

Admixture (Kg) | 30±1% | |

Discharge Height (m) | 3.8 | |

- Q: What raw materials and equipment do you need for your own admixture?

- The main ingredients of admixtures are: the mother fluid, the composition of the air and the composition of the mixture, and the water. The concrete formulations are determined according to the different materials of concrete, which is usually the mother solution and the adjustment time. The parent fluid is itself well adapted and does not require a lot of material. Complex admixtures do not require any other equipment except for the geosyncline configuration.

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Give you a website to see. Specializing in concrete mixing stations. Hope that useful.

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZS refers to the production capacity per hour. The specifications of the mixing plant size is named according to the theory of production per hour, the specifications of the commonly used at present in our country are: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240 etc. Such as: HZS25 refers to the production capacity of 25 cubic meters per hour mixing station, the host for the double shaft mixer. If the host to use single model for HZD25 horizontal spindle

- Q: How long does it take to build a concrete mixer station?

- Normally, between one and three weeks. Plan the main points of the stirring station Venue: single 2m3, 3m3, the equipment occupies an area of about 21mx51m. Add in the yard, parking lot, road, office building, repair shop, recycling pool and so on, usually need the site 40mx80m (the land of 5 acres). 2m3 and 3m3 stations usually require 60mx80m (7.5 acres). If the location is more complex, the layout of the equipment should be based on the utilization of the site. To reduce the cost of future operations, it is suggested that there be a river at the edge of the site so that it can be used to carry sand stones. Distance should consider the best range of concrete delivery vehicles, not too far away from the main site, but also for future development. Optional: choose according to the expected amount of concrete. In a year of 300 working days, eight hours a day, the actual efficiency is lower than the nominal value given the various factors that are affected. Considering the requirement of the equipment for regular maintenance and maintenance, and the requirement of the high demand in some period, it is suggested that the equipment should be purchased. In some areas, the construction of new concrete and concrete stations must be at least two.

- Q: Classification of concrete mixing stations

- There is the distinction between level 1, level 2, level 3. Because some projects, especially the project of the state, are required to provide the units of concrete, and the quality is low because of the low quality. There is a clear list of bids in general.

- Q: What are the advantages of HZS series of concrete mixing stations

- Is economical and practical type of small and medium sized concrete mixing station mixing plant, usually more than township, built in the smaller areas, compared with large mixing station the installed it easier, and covers an area of small, transportation is convenient.

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q: Concrete mixstations belong to no special equipment

- Special equipment is referred for life safety, greater danger of boilers, pressure vessels (including gas cylinders, hereinafter the same), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities. The boiler, pressure vessel (air bottle), pressure vessel is the pressure type special equipment; Elevator, hoisting machinery, passenger rope and large amusement facilities are special equipment for mechanical and electrical equipment.

- Q: The mixing time of the concrete mixer is in which standard

- Concrete quality control standard gb50164-2011

Send your message to us

HZS100 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords