HZS75 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HZN/S Series Mobile Concrete Batching Plants are the result of advanced technology and engineering skills. They are new generation Batching Plants, the fruits of extensive R&D work, experience and accurate production facilities. This key concrete equipment is commonly used in large and medium-sized construction projects that need frequent site relocations, such as hydropower stations, roads, ports and so forth.

HZN/S Series Mobile Concrete Batching Plants can go thousands of kilometres on its own axle with a single towing vehicle for instance a trailer. Comparing other concrete batching plants, its advantages include:

☆ Compact design

☆ Easy installation and start-up

☆ Less foundation costs

☆ Fully automatic robust control system

☆ Reliable units (Siemens, WAM,Telemecanique, Beckhoff, Jotun, Pirelli etc.)

☆ Technologic and high quality production

PRODUCT DETAILS

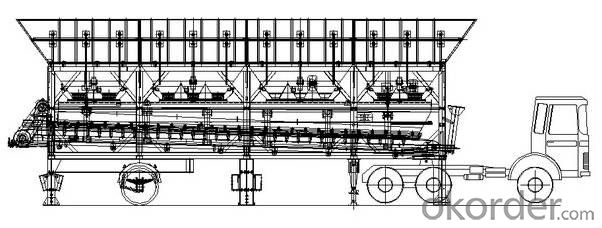

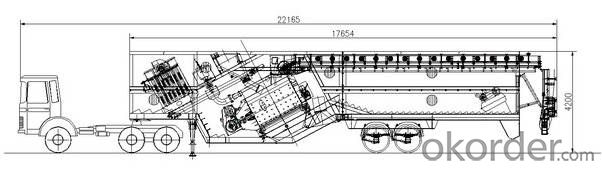

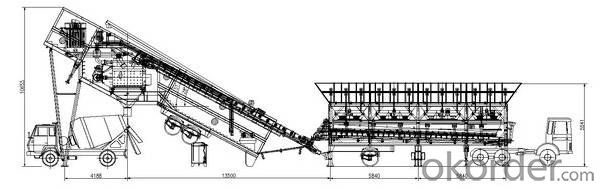

1. The aggregate weighing and conveying system, water supplying and additive agent supplying systems, weighing systems, mixing system, electrical control system and pneumatic system are fitted in one trailer.

2. Adopting module structure, designed as per the loading of standard container. All modules are in one trailing unit, it is easy for installation and disassembly and convenient for relocation.

3. Twin-shaft mixing host gives good product quality and high production efficiency. Perfect mixing can be done within ideal time period for dry-hard, half-dry-hard, plastic concrete and other types of concrete.

With discharge height at 3.8 m, it can work with any truck mixers.

4. It can store two or four types of aggregates at the same time and also with two cement silos and their respective screw conveyors;

5. All weight elements and control elements of weight system are from international well-known brands, controlled by computer, guaranteeing completely reliable and accurate weighing in rough conditions.

6. Platform or ladders equipped to each part needing maintenance and repairing. Good for maintenance.

7. The whole systemic computerized with dynamic panel display, to show clearly of the status of each component. Visualized monitor interface provides clear and real-time conditions of the site work. The plant operation data can be saved and printed out.

8. Electrical control system from international famous brands functions stably and powerfully. Automatic detection of abnormal working condition makes it easy for maintenance and trouble shooting.

9. It can be operated automatically or manually, and it is easy to switch between different operation modes.

SPECIFICATIONS

Model | HZS75 | |

Output (m3/h) | 75 | |

Mixer | Model | JS1500 |

Mixing Power (kW) | 2×30 | |

Discharging Volume (m3)) | 1.5 | |

Aggregate Size (Gravel/Pebble) (mm) | ≤60/80 | |

Aggregate Dosing Tank Capacity (m3) | 8 | |

Hoisting Motor Power (kW) | 22 | |

Weighing Range and Accuracy | Aggregate (Kg) | 3000±2% |

Cement (Kg) | 800±1% | |

Fly Ash (Kg) | 200±1% | |

Water (Kg) | 300±1% | |

Admixture (Kg) | 30±1% | |

Discharge Height (m) | 3.8 | |

- Q: What is the concrete of the mixing station?

- I am at the work station, the concrete mixing plant is operating goods, use the material such as cement, fly ash, sand, water reducing agent in strict accordance with the provisions of the state standard the ratio of mixing, through concrete truck mixer (commonly known as "car" river) transportation to the construction site, recycled concrete pump for handlebar concrete on the building site. For building products safety, now the big building construction are banned to mix concrete, concrete supply must to the recognition of concrete mixing station to buy, hope to help you.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- The mixing host of HZS90 concrete mixing station can be matched with the JS double sleeper shaft reinforced concrete mixer or imported concrete mixer host. The host is equipped with dust collecting machine, which has automatic dust collecting, dehumidification, exhaust, and the ability to recycle the collected dust to the main engine. The dust is excellent. The top of the cement bin is equipped with cylinder dust collecting machine, which is efficient and low noise. The main frame is packed in color plate, neat, beautiful and dustproof, with good view. Double post integrated installation, convenient operation and economical site. HZS90 concrete mixing station, the theoretical productivity of the device is 90 cubic meters per hour. The mixing host is the JS1500 type strong mixer, the nominal capacity is 1500L. The toppings are 1600L, the maximum productivity of the screw conveyor is 80t/h, and the maximum particle diameter is 80mm. Cement weighing accuracy and range (0 ~ 900) plus or minus 1% kg, admixtures weighing accuracy and range (0 ~ 50) plus or minus 1% kg, aggregate weighing range and precision of 0 x 5000 plus or minus 2%, HZS90 commodity concrete mixing station - unloading height is 3.8 meters, can be appropriately increase or decrease in height, in order to satisfy the demands of discharge conveyor. The standard reference weight is 97 x 103kg, which needs strong base to stabilize the mixing station

- Q: What constitutes the js750 concrete mixing station

- The concrete mixing station consists of the mixing system, the aggregate supply system, the measuring system, the control system and the external supporting equipment. The main purpose of the mixing station is to mix concrete, also called concrete mixing station. HZS series products adopt international popular cement concrete mixing station quickly assembled module type structure, high-performance imported agitator, double machine double control way of computer control, prevent noise, prevent dust pollution, environmental design, is the new generation of cement concrete mixing equipment, applicable to urban commodity ready-mixed concrete, road and bridge, water conservancy, airports, ports and other large infrastructure construction project and concrete demand for large sites.

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: Classification of concrete mixing stations

- There is the distinction between level 1, level 2, level 3. Because some projects, especially the project of the state, are required to provide the units of concrete, and the quality is low because of the low quality. There is a clear list of bids in general.

- Q: What are the facilities of the concrete mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system

- Q: What are the advantages of HZS series of concrete mixing stations

- Is economical and practical type of small and medium sized concrete mixing station mixing plant, usually more than township, built in the smaller areas, compared with large mixing station the installed it easier, and covers an area of small, transportation is convenient.

- Q: What chemical materials are used in the concrete mixing station?

- Do you mean admixtures? You want to make sure that you have a function, what purpose do you want to be able to make clear, usually with a buffer, a dilatant, and a densifier, and so on

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q: What is the difference between a concrete mixer and a concrete mixer

- The simple point is: the bones of the mixing tower are on top, and the bone is measured directly into the blender. The bone material of the stirring station is below, and the bone material is measured and then transported into the blender after the slanting belt. In a popular way, it is called the building, which is called the second ascent. Higher initial investment mixing floor production line 400000 station, because of mixing building bin above, therefore the steel structure will be bigger, inclined belt will be relatively longer. But in productivity, the churn is about 20 per cent more productive. In the operation, the energy consumption and the failure rate will increase due to the frequent start of the inclined belt of the mixing station, while the mixing building will be relatively low. Of course, in appearance, the mixing building is a bit more imposing than a mixer-stand, which can sometimes have an unexpected effect on the business. In addition, there are some technology mixing buildings that can be used, and the mixing stations can't be used, because the equipment is different. It's worth noting that the difference between the initial and the mixing stations is not absolute.

Send your message to us

HZS75 Mobile Concrete Batching Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords