Asphalt&bitumen batching plant LB2000 with capacity 160t/h, bitumen plant in Canada

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

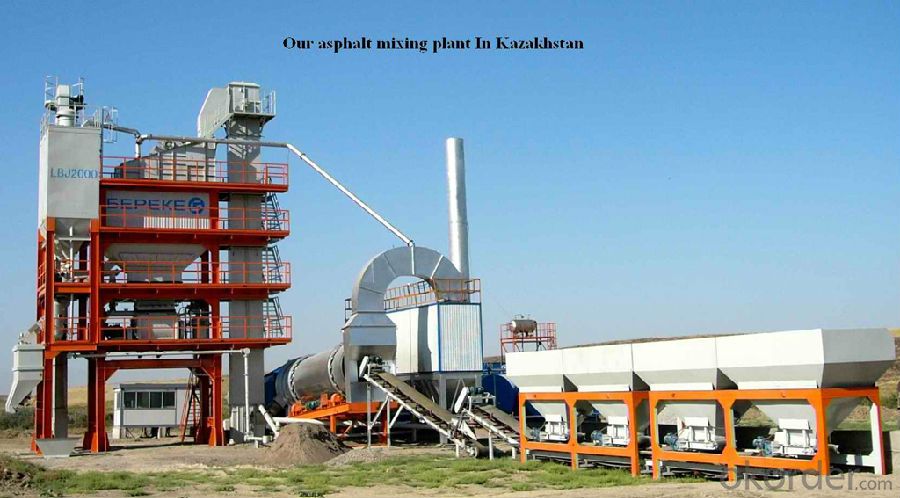

Specification of asphalt&bitumen mixing plant LB2000

| Item | Technical data | ||||

| Aggregate supply system (primary batching device ) | Hopper wall vibrator (2 units) | Motor power | 0.25KW | ||

| Collecting Conveyor belt | Belt width | 650MM | |||

| Productivity | 200T/H | ||||

| Motor power | 4 KW | ||||

| Drying drum | Dimension | 2.3 X 8.2M | |||

| Materials | Steel plate 16/20g | ||||

| Installation angle | 5o | ||||

| Drying drum drive motor | 4 X 15 KW | ||||

| Drying drum rotational speed | 7.7RPM | ||||

| Burning system | Imported oil burner (Optional) | Atomizing medium (optional) | |||

| Model | ZZR2000 (Canada Digi Burner) | ||||

| Power of blower | 15KW | ||||

| Power of oil pump | 2.2KW | ||||

| Screw air compressor | 22KW X 1 | ||||

| Gas consumption | 3M3/MIN | ||||

| Air pressure | 0.6MPa | ||||

| Heavy oil tank | 10T(with oil duct) | ||||

| Diesel tank | 10T(with oil duct) | ||||

| Fuel Type | diesel oil, heavy oil and residual oil | ||||

| Atomizing machinery (optional) | |||||

| Model | EB8N (Italy Burner) | ||||

| Composition | Blower oil,pump,console etc. | ||||

| Heavy oil tank | 10T(with oil supplying pipeline) | ||||

| Diesel tank | 10T(with oil supplying pipeline) | ||||

| Bag dust collector (Optional) | Bag material | NOMEX weight 500g/m2,removing dust easily | |||

| Dust collecting area | 670M3 | ||||

| Air volume | 55000M3/H | ||||

| Compressed air consumption | 2.6M3/MIN | ||||

| Compressed air pressur | 0.4~0.7Mpa | ||||

| Normal working temperature | 100175 | ||||

| Instantaneous max heatresisting | 230 | ||||

| Air compressors | Type | LB150320 | |||

| Motor power | 11KW X 2 | ||||

| Air consumption | 1.67M3/MIN | ||||

| Gas storage tank | 0.6M3 | ||||

| Dust recycling system | Hanging style rotation loader power | 0.75KW | |||

| screw conveyer powert | 4KW | ||||

| Inside spin power | 4KW | ||||

| Recycle powder hoist | 4KW | ||||

| draught fan | Fan motor power | 110KW | |||

| fan wind air volume | 36762~69347M3/H | ||||

| fan wind pressure | 28243874Pa | ||||

| Auxiliary draught fan | Fan motor power | 3kw | |||

| fan wind air volume | 3456~69347M3/H | ||||

| fan wind pressure | 9171210Pa | ||||

| The chimney | Height | 15M | |||

| Exit dust exhaust concentration | <100mg/Nm3 | ||||

| Vibrating screen | Vibration frequency |

| |||

| Amplitude | 6~8MM | ||||

| Screen areas | 18.6 M2 | ||||

| Production capacity | ≥200T/H | ||||

| Drive motor power | 11KW | ||||

| Screen mesh specification | 35X35,22X22,11X11,6X6MM | ||||

| Hot aggregate elevator | Type | duplex chain hopper | |||

| Chain form | double chain ,automatic tensioner | ||||

| Electromagnetic brake motor reducer | Power | 18.5KW | |||

| Chain speed | 1.2M/S | ||||

| Speed reducer power | 15KW | ||||

| Height | 14.8M | ||||

| Hoisting capacity | 200T/H | ||||

| Hot aggregate bin | Type | 4 compartment hoppers | |||

| Hopper volume | 36.7M3 | ||||

| Weighing system | Hot aggregate scale hopper | volume | 2.1 M3 | ||

| Static measuring precision | ±0.5% | ||||

| Weighting modularity sensor | HM-E-A-2 (Meidiya) | ||||

| Powder weighing hopper | volume | 0.41M3 | |||

| Static measuring precision | ±0.25% | ||||

| Weighting modularity sensor | HM-E-A-0.3 (Meidiya) | ||||

| Powder screw conveyer | LSL273×3020×4 | ||||

| Screw conveyer power | 4KW | ||||

| Asphalt weighing hopper | volume | 0.3M3 | |||

| Static measuring precision | ±0.25% | ||||

| modularity sensor | HM-E-A-0.2 (Meidiya) | ||||

| The asphalt measuring pump | 7.5kw | ||||

| The asphalt spraying pump | 11kW | ||||

| Tower frame | Dimension | 8800*2250*2500 | |||

| The mixer | Type |

| |||

| Volume | 2000kg /batch | ||||

| Cycle time | 45s | ||||

| Drive motor power | 37KW×2 | ||||

| Monitor room | Overall dimension | 5M X 2 M X 2.5 M | |||

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Which have so many requirements, sand silt content not too many, too many big rocks, soil, too much, artificial sand and river sand can, had better not use weathering sand, not according to the standard to which have the standard, is to see the skill of your lab

- Q: The main components of a mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system.

- Q: What is the concrete of the mixing station?

- Concrete mixing stations are made of concrete, which is made of concrete for various construction sites, including commercial housing, concrete floor, industrial workshop and so on.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- The mixing host of HZS90 concrete mixing station can be matched with the JS double sleeper shaft reinforced concrete mixer or imported concrete mixer host. The host is equipped with dust collecting machine, which has automatic dust collecting, dehumidification, exhaust, and the ability to recycle the collected dust to the main engine. The dust is excellent. The top of the cement bin is equipped with cylinder dust collecting machine, which is efficient and low noise. The main frame is packed in color plate, neat, beautiful and dustproof, with good view. Double post integrated installation, convenient operation and economical site. HZS90 concrete mixing station, the theoretical productivity of the device is 90 cubic meters per hour. The mixing host is the JS1500 type strong mixer, the nominal capacity is 1500L. The toppings are 1600L, the maximum productivity of the screw conveyor is 80t/h, and the maximum particle diameter is 80mm. Cement weighing accuracy and range (0 ~ 900) plus or minus 1% kg, admixtures weighing accuracy and range (0 ~ 50) plus or minus 1% kg, aggregate weighing range and precision of 0 x 5000 plus or minus 2%, HZS90 commodity concrete mixing station - unloading height is 3.8 meters, can be appropriately increase or decrease in height, in order to satisfy the demands of discharge conveyor. The standard reference weight is 97 x 103kg, which needs strong base to stabilize the mixing station

- Q: Classification of concrete mixing stations

- Commercial concrete mixing station: single/double HZS90 concrete mixing station, single/double hzss120 concrete mixing station, single/double hzss240 concrete mixing station, single/double hzss240 concrete mixing station. Engineering concrete mixing station: HZS75 concrete mixing station, HZS60 concrete mixing station, HZS50 concrete mixing station, HZS35 concrete mixing station, HZS25 concrete mixing station. Mobile concrete mixer station

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: What are the advantages of HZS series of concrete mixing stations

- Concrete mixing plant is composed of ingredients, mixing and electric control system components made sets of fully automatic concrete mixing equipment, and equipped with a separate manual control, automatic fall compensation, sand moisture content of compensation, can automatically accomplish the tank production. The theory of productivity 75 cubic meters/hour, discharging height is 3.8 meters, the storage hopper volume of 8 cubic * 3 warehouse or 4 warehouse, supporting the host is forced JS1500 type and double shaft mixer

- Q: What chemical materials are used in the concrete mixing station?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, the general commodity concrete mixing station will write like this, the benefit of writing is simple and convenient, because the concrete three words are really too complicated! Zhengzhou zhengchen industrial production commodity concrete mixing station equipment.

Send your message to us

Asphalt&bitumen batching plant LB2000 with capacity 160t/h, bitumen plant in Canada

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords