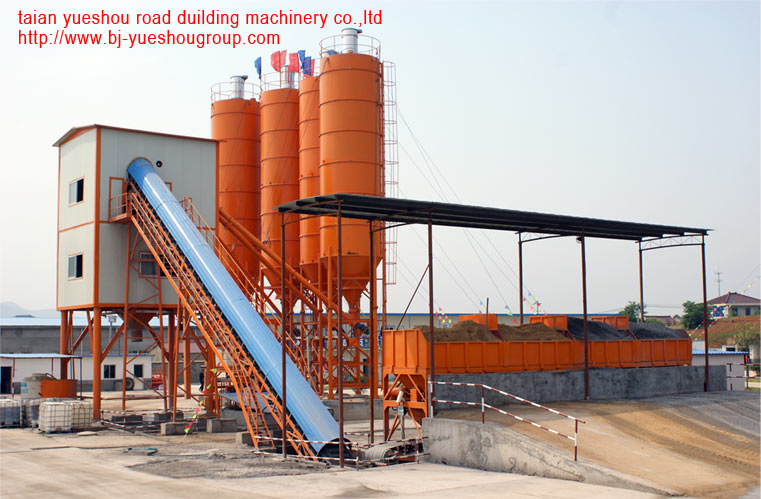

High quality concrete mixing plant production capacity 35m3 per hour

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ready mixed concrete batching plant with bucket elevatorconcrete batching plant with CE

capacity is 35m3/hour

with CE,ISO

Ready mixed concrete mixing plant with capacity 35 m3/hour, hot sale concrete batching plant with bucket elevator

Our concrete batching plant has more than 23 years history. The concrete batching plant has passed CE, ISO, CCC. We have 200 technicians for our backup force.

HZS35,Concrete Batching Plant,35m3/h,manufacturer, Construction machine

1. The mixer

Model: JS750

Type: twin-horizontal force stirrer

Charging volume: 1200L

Discharging volume: 750L

Discharging height: 3.8m

Motor power: 18.5×2KW

2. Charging elevating hopper

Hopper volume: 1200t/h

Motor Power: 7.5KW

3. Aggregate weighing system

Aggregate storage volume: 3×5m3

Scale hopper volume: 1500L

Measuring manner: individual measuring

Sensors: 4×2000kg

Measuring precision: ±2/100

Strap conveyer belt: 1.25m/s

4. Cement weighing system

Scale hopper volume: 2000L

Weighing rang: 0-2000kg

Weighing precision: ±1/100

Sensor: 3×500kg

5. Flyash weighing system

Scale hopper volume: 450L

Weighing range: 0-4500kg

Weighing precision: ±1/100

6. Water weighing system

Water scale hopper volume: 500L

Weighing precision: ±1/100

Pump motor power: 3KW

7. Additive weighing system

Scale hopper: 40L

Additive storage: 1m3

Weighing precision: ±1/100

Pump motor power: 0.37KW

8. Pneumatic system

Air compressor: 5.5KW

9. Screw conveyer

Format | Delivery Capacity | Motor power |

Φ168 | 25t/h | 7.5KW |

Φ219 | 45t/h | 7.5KW |

10. Powder storage

Specification: 300t×2 or 200t ×3

- Q: What is the concept of on-site concrete mixer station

- The concrete mixing station is at the construction site to set up a soil mixing concrete equipment, including automatic conveying equipment, measuring equipment, concrete mixing equipment, cement storage warehouse etc.

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: Classification of concrete mixing stations

- There is the distinction between level 1, level 2, level 3. Because some projects, especially the project of the state, are required to provide the units of concrete, and the quality is low because of the low quality. There is a clear list of bids in general.

- Q: What are the facilities of the concrete mixing station

- One. Stir the host The mixing machine is divided into strong mixing and self-falling stirring. The powerful mixer is the mainstream in the domestic and foreign mixers, it can stir the liquid, semi-dry hard and hard and so on. The main mixing liquid concrete of the self-falling mixer is very rarely used in the mixing station. Two. Material transport system The material transport consists of three parts. Aggregate conveying; There are two ways of conveyance and belt conveyance. The advantage of hopper promotion is that the area is small and the structure is simple. The advantage of belt transport is that the transport is large, efficient and low. The belt conveyor mainly applies to the mixing stations that have aggregate storage, thereby increasing the productivity of the mixing stations. Powder conveying; The powder used in concrete is mainly cement, fly ash and mineral powder. The most commonly used powder conveyors are conveyors of screw conveyors, and the large mixing buildings are carried by pneumatic conveyer and scraper. The advantages of screw transport are simple structure, low cost and reliable use. Liquid transport mainly refers to water and liquid admixtures, which are delivered separately by water pumps.

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q: What is the special work of the concrete mixing station

- Mixer operator, welder, tester, loader driver's license, assessor

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- What is the amount of cement in the concrete mixing station? This is based on the different levels of the concrete mix. Here is a different grade of concrete ingredients: Note: 1. The mix of concrete and concrete shall be carried out in uniform ratio of gravel and slump. In one project, the C40 is mixed with ordinary cement, and according to the proportion design, the maximum amount of coal ash can replace 40% of the cement consumption.

- Q: What is the difference between a concrete mixer and a concrete mixer

- Since a lot of people think commodity concrete, concrete stand and commodity concrete mixing floor are production of commodity concrete equipment, then there is no too big difference, most is just a big a small, one high a dwarf. But what's the difference between these two devices? So let's just do a little bit of an introduction. First commercial concrete, concrete stand and mixing building systems: the difference between a bituminous concrete stand composed of five systems, such as material supply system, measuring system, mixing system, electric control system, etc. The stirring building is relatively simple.

- Q: The mixing time of the concrete mixer is in which standard

- The quality control standard gb50164-2011 should not be produced for 40 seconds in the winter of 30 seconds

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, the general commodity concrete mixing station will write like this, the benefit of writing is simple and convenient, because the concrete three words are really too complicated! Zhengzhou zhengchen industrial production commodity concrete mixing station equipment.

Send your message to us

High quality concrete mixing plant production capacity 35m3 per hour

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords