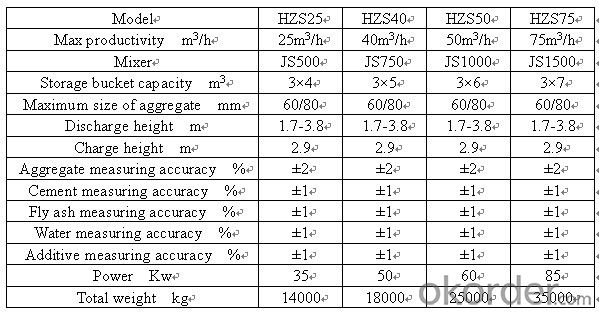

concrete batching plant HZS40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

This concrete mixing station has higher intelligent automation function, which is a small and medium sized forced-type mixing station, featuring compact structure, flexible layout, low investment, convenient transport and disassembly, which are favored by users.

The station is composed of material supply, metering system, mixing system, electrical control system, pneumatic control system, etc., which can mix various types of concrete, and is especially suitable for mixing dry and hard concrete, which is applicable for at least medium-sized construction engineering, water and electricity, roads, ports, docks, bridges and other projects as well as larger and medium-sized manufacturing factories and concrete production plants.

The station can store three different types of aggregates. Charging is realized via loaders. Three cement silos and the corresponding spiral conveyor are equipped. Aggregates, additives, water and cement are all measured with electronic scales. The main machine of the mixers is of twin-shaft type, featuring good mixing quality and high production efficiency. The station can be run either automatically under computer control or manually. The computer controlled system has dosing storage, drop automatic compensation, exception case alerts and other functions. The control parameters can be modified randomly and do not loss in the case of power failure. It is also equipped with a printer. (Cement silo and spiral conveyor are ordered by the user specially). In addition, the control system employs bilingual control, which can facilitate the operation of operators.

- Q: What is the concrete of the mixing station?

- What else can you do to sell concrete What is the station

- Q: Cement warehouse introduction, storage reserves?

- There's nothing to come, but warm and young About 200 tons

- Q: How much concrete is produced per hour by HZS180 concrete mixer?

- HZS180 concrete production line equipment production line equipment per hour theory produces 180 cubic concrete. It depends on the equipment situation. Henan zheng a heavy industrial concrete mixing plant equipment factory

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZ is the concrete mixing station. HZ is the concrete mixer. HZS is a concrete mixing station with a double sleeper shaft mixer

- Q: What are the ingredients for the concrete mixing stations?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials.

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q: What chemical materials are used in the concrete mixing station?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

- Q: Which staff does the concrete mixing station need?

- Move the cement iron pipe, driver! technology, webmaster, laboratory (deputy) director of the general, production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians,

Send your message to us

concrete batching plant HZS40

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords