HZS 40 Mobil concrete batching plant

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

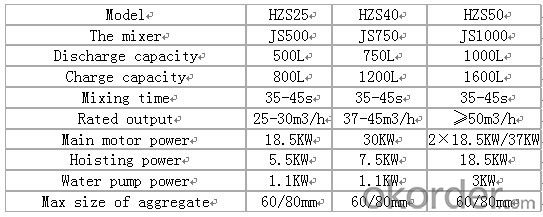

YHZS mobile concrete batching plant is highly integrated concrete batching plant. The main mixer adopt double-shaft compulsory mixer, have the advantage of low mixing time, discharge quickly, mixing equality and high productivity, can produce plastic, dry-hard and other concrete, reliable quality. Aggregate adopt electronic scale cumulative measurement or single measurement, cement、water、admixture are used weighing hopper, accurately measurement, computer centralized control, simple operation, easy adjustment and reliable quality. Aggregate adopt two kinds of feeding method: upgrade hopper or belt conveyor. Electrical components adopt Siemens device, reliable performance and high productivity, suitable for large quantities of concrete which is on site production. The mixer’s scale board and mixing blade using wear-resistant material which has processed special, the special shaft bearing and seal type has greatly improve the life of the mixer.

This machine is functional and consisted by bathing system, mixing system, measuring system and control system, small size, cost-effective, suitable for small or medium-scale hydropower, roads, ports, airports, bridge and other mobility projects.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- Many manufacturers will say that the HZS90 station is the one that makes 90 square concrete. In fact, the HZS90 station is supposed to produce 90 square concrete when it is in theory, and it is actually not up to 75 square

- Q: Cement warehouse introduction, storage reserves?

- This one has a lot of small, see how to configure, usually at 200 tons above each warehouse

- Q: What is the concept of on-site concrete mixer station

- It's not a simple blender. It's not a simple blender. But an intensive production scale small and use the site concrete, according to the need to establish a set of automatic production line, divided into according to production output per hour 35 square (45), 50 square (60), 75 (90), 90 (120), the standard station with laboratory; To establish the corresponding scale of the stations according to the construction needs; This kind of mixing station can not only guarantee the quality of concrete, but not the time factor, which guarantees that 24 hours can produce the concrete needed for the site. He needs to have about 30, 000 or so in demand, and the site is suitable. This has low cost, convenient site management and mutual benefit!

- Q: How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

- Q: How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q: What are the facilities of the concrete mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system

- Q: What is the special work of the concrete mixing station

- One of the features of the high-performance concrete mixer line is the low water ratio. In order to ensure its liquidity, it must be mixed with an efficient water reducer. Therefore, it is necessary to select cement that is suitable for low water cement ratio. One is the composition of fineness and particles, and the other is the early hydrogenation after the addition of water.

- Q: What chemical materials are used in the concrete mixing station?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials

- Q: Concrete mixstations belong to no special equipment

- Is not mixing station is places or facilities, equipment, for whether the equipment belongs to the special equipment to check the catalog of special equipment, included in the directory is the special equipment, is not included.

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Original concrete is the construction unit oneself mix, the existing specialized manufacturer presses the need to produce concrete, the product that produces is concrete.

Send your message to us

HZS 40 Mobil concrete batching plant

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords