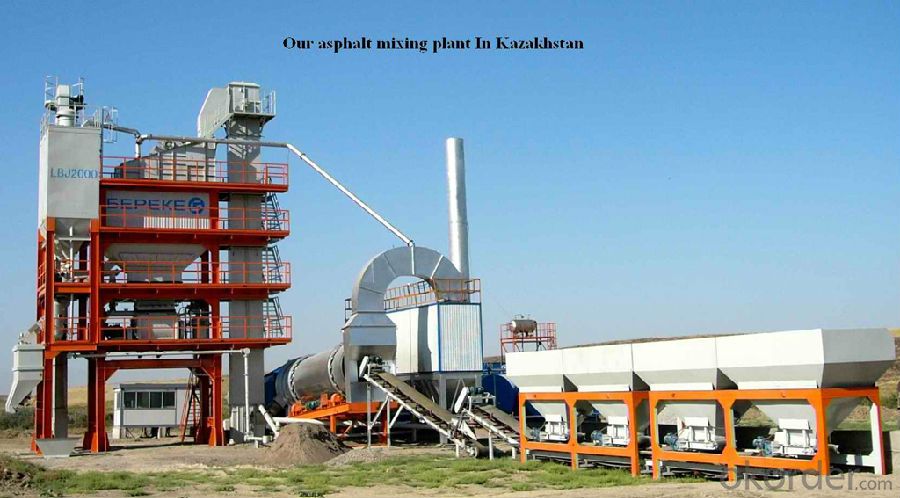

Asphalt Batching Plant with productivity of 160t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification of asphalt&bitumen mixing plant LB2000

| Item | Technical data | ||

| Aggregate supply system (primary batching device ) | Hopper wall vibrator (2 units) | Motor power | 0.25KW |

| Collecting Conveyor belt | Belt width | 650MM | |

| Productivity | 200T/H | ||

| Motor power | 4 KW | ||

| Drying drum | Dimension | 2.3 X 8.2M | |

| Materials | Steel plate 16/20g | ||

| Installation angle | 5o | ||

| Drying drum drive motor | 4 X 15 KW | ||

| Drying drum rotational speed | 7.7RPM | ||

| Burning system | Imported oil burner (Optional) | Atomizing medium (optional) | |

| Model | ZZR2000 (Canada Digi Burner) | ||

| Power of blower | 15KW | ||

| Power of oil pump | 2.2KW | ||

| Screw air compressor | 22KW X 1 | ||

| Gas consumption | 3M3/MIN | ||

| Air pressure | 0.6MPa | ||

| Heavy oil tank | 10T(with oil duct) | ||

| Diesel tank | 10T(with oil duct) | ||

| Fuel Type | diesel oil, heavy oil and residual oil | ||

| Atomizing machinery (optional) | |||

| Model | EB8N (Italy Burner) | ||

| Composition | Blower oil,pump,console etc. | ||

| Heavy oil tank | 10T(with oil supplying pipeline) | ||

| Diesel tank | 10T(with oil supplying pipeline) | ||

| Bag dust collector (Optional) | Bag material | NOMEX weight 500g/m2,removing dust easily | |

| Dust collecting area | 670M3 | ||

| Air volume | 55000M3/H | ||

| Compressed air consumption | 2.6M3/MIN | ||

| Compressed air pressur | 0.4~0.7Mpa | ||

| Normal working temperature | 100175 | ||

| Instantaneous max heatresisting | 230 | ||

| Air compressors | Type | LB150320 | |

| Motor power | 11KW X 2 | ||

| Air consumption | 1.67M3/MIN | ||

| Gas storage tank | 0.6M3 | ||

| Dust recycling system | Hanging style rotation loader power | 0.75KW | |

| screw conveyer powert | 4KW | ||

| Inside spin power | 4KW | ||

| Recycle powder hoist | 4KW | ||

| draught fan | Fan motor power | 110KW | |

| fan wind air volume | 36762~69347M3/H | ||

| fan wind pressure | 28243874Pa | ||

| Auxiliary draught fan | Fan motor power | 3kw | |

| fan wind air volume | 3456~69347M3/H | ||

| fan wind pressure | 9171210Pa | ||

| The chimney | Height | 15M | |

| Exit dust exhaust concentration | <100mg/Nm3 | ||

| Vibrating screen | Vibration frequency | 19Hz | |

| Amplitude | 6~8MM | ||

| Screen areas | 18.6 M2 | ||

| Production capacity | ≥200T/H | ||

| Drive motor power | 11KW | ||

| Screen mesh specification | 35X35,22X22,11X11,6X6MM | ||

| Hot aggregate elevator | Type | duplex chain hopper | |

| Chain form | double chain ,automatic tensioner | ||

| Electromagnetic brake motor reducer | Power | 18.5KW | |

| Chain speed | 1.2M/S | ||

| Speed reducer power | 15KW | ||

| Height | 14.8M | ||

| Hoisting capacity | 200T/H | ||

| Hot aggregate bin | Type | 4 compartment hoppers | |

| Hopper volume | 36.7M3 | ||

| Weighing system | Hot aggregate scale hopper | volume | 2.1 M3 |

| Static measuring precision | ±0.5% | ||

| Weighting modularity sensor | HM-E-A-2 (Meidiya) | ||

| Powder weighing hopper | volume | 0.41M3 | |

| Static measuring precision | ±0.25% | ||

| Weighting modularity sensor | HM-E-A-0.3 (Meidiya) | ||

| Powder screw conveyer | LSL273×3020×4 | ||

| Screw conveyer power | 4KW | ||

| Asphalt weighing hopper | volume | 0.3M3 | |

| Static measuring precision | ±0.25% | ||

| modularity sensor | HM-E-A-0.2 (Meidiya) | ||

| The asphalt measuring pump | 7.5kw | ||

| The asphalt spraying pump | 11kW | ||

| Tower frame | Dimension | 8800*2250*2500 | |

| The mixer | Type | Two horizontal forced paddle type mixer | |

| Volume | 2000kg /batch | ||

| Cycle time | 45s | ||

| Drive motor power | 37KW×2 | ||

| Monitor room | Overall dimension | 5M X 2 M X 2.5 M | |

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- If it's a theoretical one, it's going to build 90 lines per hour, which is 90 square hours per hour, and if it's actually 90 square, it's going to be at least 120 stations.

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZS refers to the production capacity per hour. The specifications of the mixing plant size is named according to the theory of production per hour, the specifications of the commonly used at present in our country are: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS150, HZS180, HZS240 etc. Such as: HZS25 refers to the production capacity of 25 cubic meters per hour mixing station, the host for the double shaft mixer. If the host to use single model for HZD25 horizontal spindle

- Q: How long does it take to build a concrete mixer station?

- The core part of the stirring station: stirring the host, electronic control system, weighing element and instrument. The mixer should choose to use the stirring stability, the maintenance is simple and convenient, the service life is long, the match is supplied with the sufficient production plant. The electric component must choose the international brand products, preferably the imported original product, to guarantee the reliable; The software of the computer system shall be developed by the manufacturer in order to be upgraded and replaced in the future. And there should be a pro version of the software (piracy is prone to malfunctions and possible intellectual property lawsuits).

- Q: What are the ingredients for the concrete mixing stations?

- Start with the glue: cement, coal ash, mineral powder, and various expansions! Sand: natural sand, mineral sand, fine sand; Stone: 5-10, 5-20 water reducer! And tap water

- Q: What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q: What is the difference between a concrete mixer and a concrete mixer

- Since a lot of people think commodity concrete, concrete stand and commodity concrete mixing floor are production of commodity concrete equipment, then there is no too big difference, most is just a big a small, one high a dwarf. But what's the difference between these two devices? So let's just do a little bit of an introduction. First commercial concrete, concrete stand and mixing building systems: the difference between a bituminous concrete stand composed of five systems, such as material supply system, measuring system, mixing system, electric control system, etc. The stirring building is relatively simple.

- Q: Which staff does the concrete mixing station need?

- Mainly depends on how big is your station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc These are the main people who want to help you.

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

- Q: The mixing time of the concrete mixer is in which standard

- The quality control standard gb50164-2011 should not be produced for 40 seconds in the winter of 30 seconds

- Q: Does the concrete mixing station name have the name of the businessman concrete

- Yes, concrete means artificial stone, which can be understood as the simple writing of concrete, which means concrete for commercial concrete. This is the name of the blender

Send your message to us

Asphalt Batching Plant with productivity of 160t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords