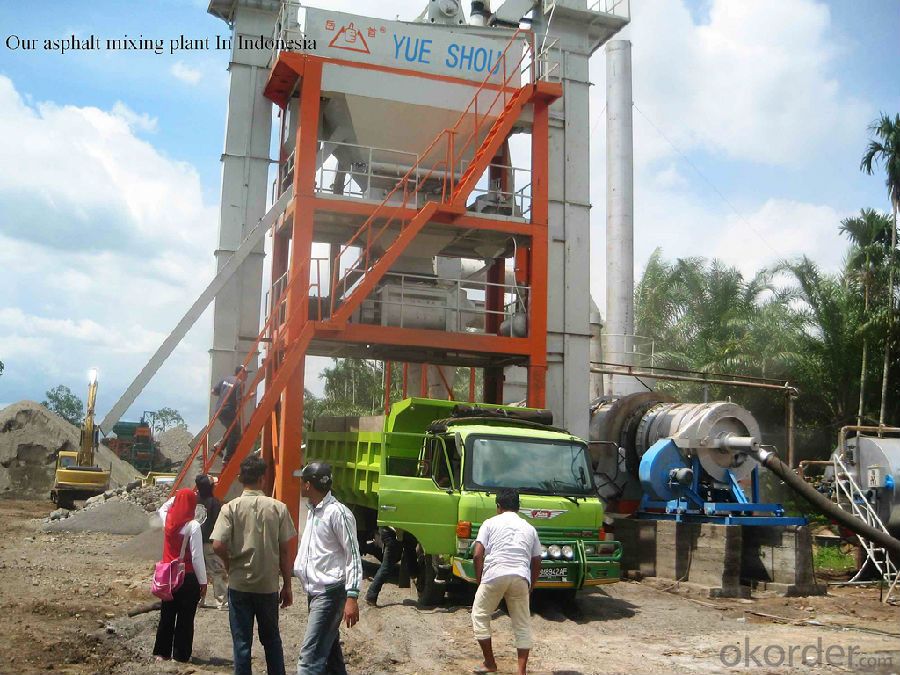

Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q: What raw materials and equipment do you need for your own admixture?

- The admixture of concrete mixing station using a lot of more phyletic, the effect is different also, early strength agent, retarder, water reducing agent, and release agent, antifreeze, etc., which is a kind of do not know you to call. The admixtures are usually made by professional manufacturers, and the ingredients are not the same.

- Q: The main components of a mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system.

- Q: What type of concrete mixer is needed for each hour of concrete 90 cubic meters?

- The mixing host of HZS90 concrete mixing station can be matched with the JS double sleeper shaft reinforced concrete mixer or imported concrete mixer host. The host is equipped with dust collecting machine, which has automatic dust collecting, dehumidification, exhaust, and the ability to recycle the collected dust to the main engine. The dust is excellent. The top of the cement bin is equipped with cylinder dust collecting machine, which is efficient and low noise. The main frame is packed in color plate, neat, beautiful and dustproof, with good view. Double post integrated installation, convenient operation and economical site. HZS90 concrete mixing station, the theoretical productivity of the device is 90 cubic meters per hour. The mixing host is the JS1500 type strong mixer, the nominal capacity is 1500L. The toppings are 1600L, the maximum productivity of the screw conveyor is 80t/h, and the maximum particle diameter is 80mm. Cement weighing accuracy and range (0 ~ 900) plus or minus 1% kg, admixtures weighing accuracy and range (0 ~ 50) plus or minus 1% kg, aggregate weighing range and precision of 0 x 5000 plus or minus 2%, HZS90 commodity concrete mixing station - unloading height is 3.8 meters, can be appropriately increase or decrease in height, in order to satisfy the demands of discharge conveyor. The standard reference weight is 97 x 103kg, which needs strong base to stabilize the mixing station

- Q: How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

- Q: How to choose a good concrete mixer station?

- For simple concrete mixup stations, the overall cost of equipment is much cheaper, because the configuration is different and a lot of configuration is eliminated. But cement weighing cannot save configuration independent water weighing measurement more accurate to efficient, do not use water weighing system can also be mixing concrete, but there is a big hidden trouble. The water weighing system is not suitable for individual water weighing system, and it can reduce the investment of a simple mixing station by about 7, 000 yuan. And shortcomings is not water in the mixing drum of the weighing system and water, time node device can be used to set the water within a certain time interval to churn, but increased water and forced concrete mixer mixing time, still can cause concrete model is not stable. Therefore, although do not use water weighing system can save investment, but will increase the mixing time of concrete and affect the stability of the concrete, so the customer can choose according to oneself circumstance.

- Q: What does HZS mean in the HZS120 concrete mixing station

- HZ is the concrete mixing station. HZ is the concrete mixer. HZS is a concrete mixing station with a double sleeper shaft mixer

- Q: What are the ingredients for the concrete mixing stations?

- It is the raw materials for the concrete mixers, the sand, stone, cement, fly ash, mineral powder, various admixtures, water, basically these seven raw materials.

- Q: The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q: Which staff does the concrete mixing station need?

- Move the cement iron pipe, driver! technology, webmaster, laboratory (deputy) director of the general, production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians,

- Q: What is the daily routine of the concrete mixing station?

- Concrete mixing station is made by mixing console, materials weighing system, material conveying system, material storage system, control system of five systems and other ancillary facilities of building materials manufacturing equipment, the main principle of work is with cement as cementing material, mixing materials such as sandstone, limestone, coal cinder stirring, finally made into concrete, as the wall materials into construction operation.

Send your message to us

Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches