Hot Sale Polypropylene Spun-boonded Garment Interlining Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

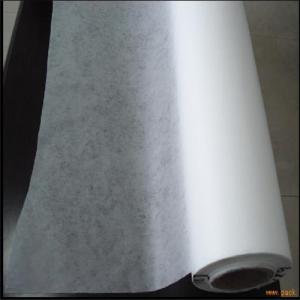

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

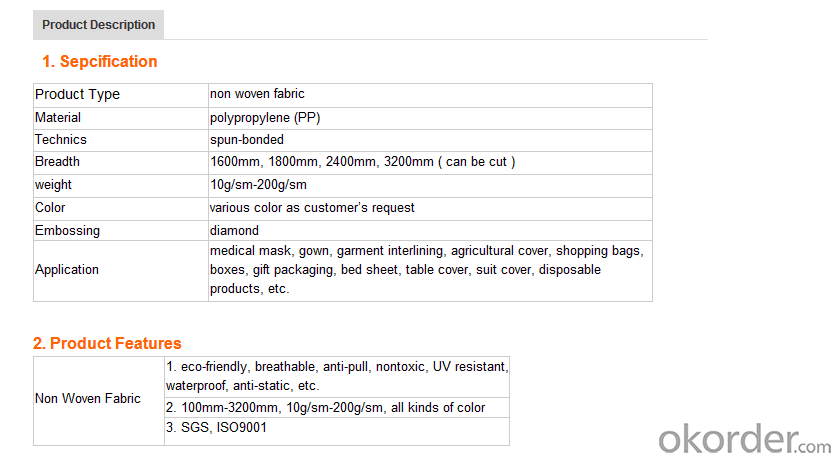

Product Specifications

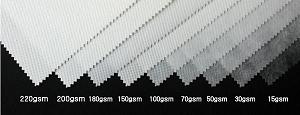

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Listed in recent years the textile industry pollutant emissions

- Sulfur dioxide emissions increased by the larger power, steam, hot water production and supply industry, ferrous metal smelting and rolling processing industry, non-metallic mineral products industry, food processing industry, chemical raw materials and chemical products manufacturing industry five industries, industrial sulfur dioxide emissions Rate of 84.4%, the growth accounted for key enterprises to investigate the total sulfur dioxide emissions of 104%

- Q: How to reduce the cost of textile yarn dyeing

- Now due to the domestic environmental protection situation is grim, dyeing and finishing agents may temporarily small ups and downs, there will not be a substantial price increases, but also not save

- Q: What is the anti-perspiration finishing of textiles?

- At the same time, the fabric hydrophilic surface in the hydrophilic, the corresponding waterproof surface can not see the watermark. At present in the knitted fabric on the anti-perspiration finishing more mature, in the weight of the lower woven fabrics, especially light-colored anti-perspiration effect is not particularly ideal

- Q: Textile printing and dyeing process which

- Dyeing is a more complex process, different quality of cloth dyeing process is different, cotton, polyester cotton, nylon, polyester, chemical fiber products, blended products and so on. Some use of pad dyeing, roll dyeing, and some must use high temperature and high pressure dyeing, and some only once, and some to color several times.

- Q: How to make fibrous textiles for waste plastic bottles?

- Jiangsu, a textile company to Beijing during the Olympic Games recycling waste plastic beverage bottles, the use of some surprising, the production of sports textile products! At the same time, Zhejiang Xiaoshan four companies at home and abroad extensive acquisition of waste plastic bottles, processed into fiber and then exported, one year consumption of 1 billion plastic bottles, the annual output value of over 500 million yuan

- Q: What are the classification of the textile?

- Weft yarn, weft yarn, weft density - fabric width direction; the yarn is called weft yarn, the number of yarns in 1 inch is the weft density (weft density)

- Q: Analysis of import and export of textile

- From the first eight months of 2011 to the first eight months of 2014, the industrial added value of textile enterprises above designated size increased by 10.7%, 10.8%, 8.3% and 7.4% respectively according to the constant prices, respectively. In the first eight months of 2014, the main indexes of textile enterprises above designated size Has entered the single-digit growth, of which the main business income growth of 8.2%, exports increased by 5.7%.

- Q: The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Shrink the fabric mainly refers to cotton, linen, silk, such as natural fabrics. The shrinkage rate is related to its own fiber, but also to its tightness.

- Q: Mechanical characteristics of textile machinery

- A major development feature of modern textile machinery is to continuously improve the speed of the machine, resulting in high yield, to reduce the number of equipment, reduce plant area, save investment and labor, with less money to achieve greater results. Table 1, Table 2, Table 3, the figures show the trend of high-speed textile machinery.

- Q: What is the earliest textile raw material?

- Chinese ancient textile, the use of hemp, silk, wool, cotton fiber as raw material, spinning (spinning sand, performance, reeling) processed into yarn after weaving (woven) and woven fabric, usually called textile

Send your message to us

Hot Sale Polypropylene Spun-boonded Garment Interlining Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches