pp non woven fabric manufacturer in china for shopping bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

pp non woven fabric for shipping bags/garment packing and so on

1)thickness:30-200gsm

2)size:160-320cm

3)color:any color is possible

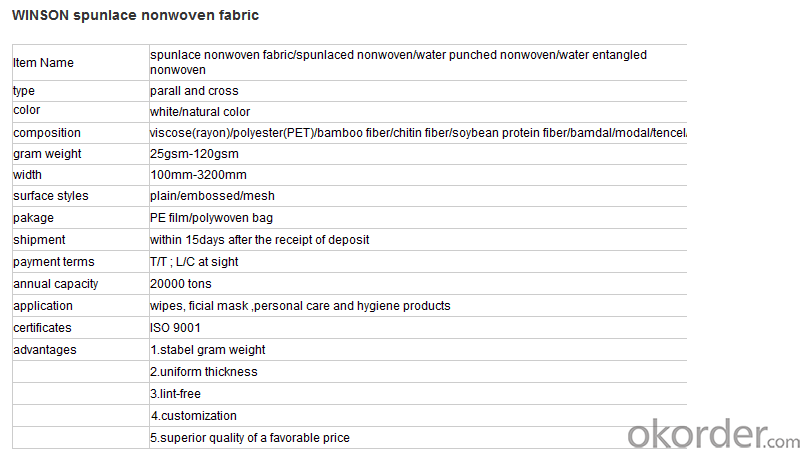

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

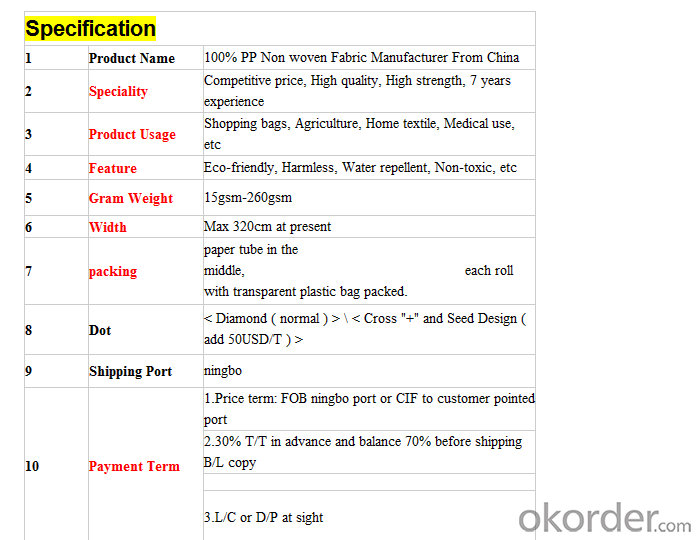

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Development of Textile Fibers.

- From the international environment, the international market is still a large expansion of space and opportunities. With the end of 2007, China and the EU textile limit expires, the end of 2008 the end of the Sino-US textile quota limit, the Chinese textile quota era is approaching, accounting for more than 60% of the global textile market share of the region fully open, will bring to China's textile trade Great opportunity.

- Q: Sponges are plastic or textiles

- The foaming resin, the foaming aid and the binder resin (the finished product having adhesiveness) are mixed together; For foam processing. 80 parts of ethylene vinyl acetate (EVA), 20 parts of APAO PT 3385, 20 parts of azodicarbonamide, 9 parts of CaCO and 0.6 part of dicumyl peroxide were mixed together and placed in a mold, And mechanical resistance to break the hole, you can get foam sponge. The density (d) is 0.028 g / cm, and the compression hardness of 25% is 1.9 KPa.

- Q: Textile finishing TPU, TPEF film. What's the difference?

- TPU cold resistance: TPU glass transition temperature is relatively low, at minus 35 degrees still maintain good flexibility, flexibility and other physical properties.

- Q: China textile products do not how points? What kind of?

- Jiangsu, Zhejiang and Shanghai textile industry's outstanding characteristics of Jiangsu and Zhejiang textile industry momentum of development, the pace of upgrading and upgrading, so that we are deeply shocked, popular inspired. To sum up, Jiangsu, Zhejiang and Shanghai textile industry has the following characteristics

- Q: Clothing and processing and processing into what auxiliaries

- Need to waterproof, plus waterproof finishing agent, the need to increase the soft, softening agent and so on. Finally processed into clothes, this part requires a relatively small amount of additives

- Q: What are the raw materials for textiles?

- You can wall wall (tapestry), not afraid of the fire and the fire (asbestos cloth, fire clothes). Like Weng woman to Tong Yan (actor dressing veil), really for the soldiers to add wings (parachute). Can protect the rocket head (aramid fiber fabric), can be used for bulletproof clothing. Enough to filter (functional fiber), where fear of electric shock (live operation taking the pressure of silk). Beauty Kam, embroidery (embroidery), odd with tapestry.

- Q: What is the specialty of textile science and engineering?

- The research contents of the textile discipline have changed obviously, and the cross and infiltration of the disciplines such as bioengineering, environmental protection engineering and material science engineering have become more and more close.

- Q: Mechanical characteristics of textile machinery

- In modern times, people's understanding of the structure and physical and chemical properties of fibers has been deepened, thus creating more and more advanced process methods, which can give full play to the characteristics of fibers and fabrics

- Q: Today, the national textile market prospects

- 2009 is known as the most difficult winter of China's textile industry in the new century, but in this winter, the textile enterprises are not afraid, more is relying on national policy support and self-adjustment to achieve the adverse trend

- Q: Jiangsu Province, more than a large number of textile and garment industry

- How to deal with today's increasingly fierce competition in the textile market, bigger and stronger city textile industry, to speed up the realization of Nantong textile market into the city's goal, which is "Eleventh Five-Year" period Nantong textile industry shoulders the arduous task.

Send your message to us

pp non woven fabric manufacturer in china for shopping bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches