Wholesale PP Non Woven Fabric For Non Woven Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

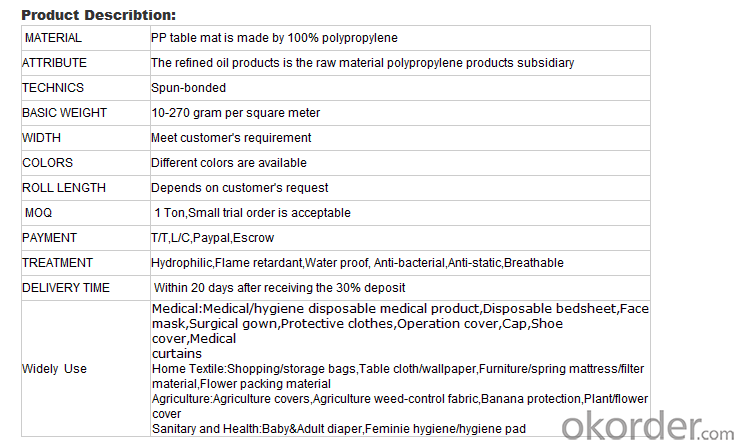

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Textile industry after finishing what pollution, especially air pollution

- Hello I am a person engaged in the field of environmental science sewage remediation industry a year first said that the current government sewage on the enterprise requirements for the main COD and ammonia nitrogen because the two will cause serious harm to the river

- Q: How to reduce the cost of textile yarn dyeing

- First analyze your cost structure: Dyeing auxiliaries, labor (including management), water and electricity, equipment

- Q: Textile machine, I should use single-phase power or three-phase electricity

- Single-phase electrical civilian electricity, if away from the transformer far, easy fluctuations in the electricity network, will cause voltage instability. Therefore, you should be based on your machine installed around the power situation to determine

- Q: Are hats a class of textile and apparel products?

- Hats are popular for textile products, processing or general trade.

- Q: Processing of textiles, processed products were detected formaldehyde exceeded, how to deal with

- Fast method can be found in the finishing of textile manufacturers, adding formaldehyde elimination agent to eliminate formaldehyde.

- Q: China textile products do not how points? What kind of?

- Industrial chain long, professional market developed. Jiangsu, Zhejiang and Shanghai region has formed from the textile raw materials, fabric weaving to dyeing and finishing, clothing production longer textile industry chain, the upper and middle and downstream products rich and varied. The textile industry has a high degree of marketization and professional market network.

- Q: What are the invoices for the textile industry?

- Ordinary invoices can not be deducted, VAT invoices for input tax can offset sales tax

- Q: What are the raw materials for textiles?

- To this many of the textile area to the categories are: fabric, knitwear, yarn rope, towel blanket Pa, non-woven fabrics and special textiles. Fabrics according to their use of raw materials to distinguish, there are: cotton, silk, woolen cloth, linen and so on. Knitwear with sweatshirts, pullovers, gloves, socks, camel hair and so on.

- Q: "Textile color standard system"

- The so-called color fastness (referred to as color fastness), refers to the dyeing fabric in the use or processing process, subject to external factors (extrusion, friction, washing, rain, exposure, light, sea water immersion, saliva impregnation, Etc.) under the effect of the degree of fading, is an important indicator of the fabric.

- Q: Mechanical characteristics of textile machinery

- The continuity of textile machinery is subject to the process. For example: spinning 20.8 ~ 27.8 cotton yarn, from cotton to spinning the total draw ratio of 13900 ~ 19000 times. The process needs to go through the cleaning of cotton, carding, parallel, roving, spun yarn and other processes, it must be distributed in the process of the corresponding equipment to complete.

Send your message to us

Wholesale PP Non Woven Fabric For Non Woven Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches