100% SMS Nonwoven Fabric, Spunbond PP Non Woven Fabric, TNT Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

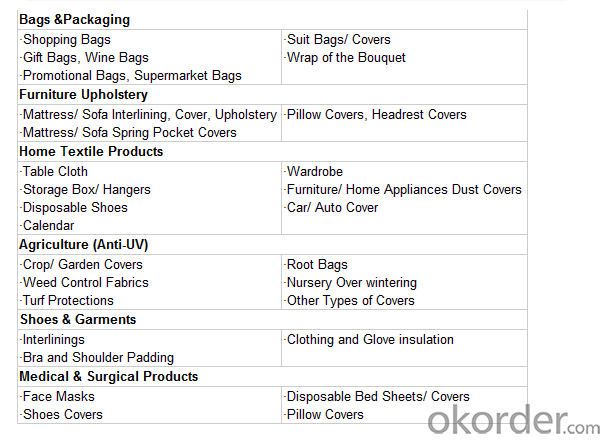

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Development of Textile Fibers.

- And the next few years the world economy will remain in the rising range, will promote the growth of international trade, which will give China's textile and garment exports to bring favorable international market protection.

- Q: Classification of textile materials

- Fiber by source and habit is divided into two categories of natural fiber and chemical fiber, or according to Anglo-American chemical fiber is divided into artificial and synthetic fiber two categories, a total of three categories. According to the material properties of the fiber nature of the natural fiber is divided into plant (class) fiber, animal (fiber) and minerals (class) fiber

- Q: What are the problems with the transformation and upgrading of the processing trade of textile enterprises?

- To ensure the stable development of the textile industry at the same time, speed up structural adjustment, promote industrial upgrading. Planning on the one hand based on the current, with a series of policies to ease the pressure on textile enterprises; the other hand, focusing on long-term, and actively promote the textile industry to speed up structural adjustment and industrial upgrading pace.

- Q: What is the step in the textile fabric

- As much as possible to understand the production and operation of the processing plant, and the factory's excellent / inferior to fully assess, so that know the root.

- Q: The Factors Affecting the Capillary Effect of Textile Garment

- The degree of removal of the pulp; the amount of impurities in the wax itself, pectin and other impurities

- Q: What are the invoices for the textile industry?

- If you are not a general taxpayer, the invoice you made when you purchased it is only an ordinary invoice, not an invoice, an invoice is invariably speaking for the general taxpayer, but some people are accustomed to buying materials or The invoice for the goods is called the invoice.

- Q: China is now optimistic about which one of the textile industry

- Medical and industrial applications and promotion of spunbond, meltblown, spunlace and its composite non-woven "three resistance" (anti-microbial, anti-blood, anti-alcohol) surgical clothing, hole towels and other medical textiles industrial production and application ; Bionic organs and other medical textile materials and products development and application

- Q: What are the classification of the textile?

- Warp, warp, warp density - the length of the fabric; the yarn is called the warp; the number of yarns in the 1 inch yarn is the density (warp density);

- Q: What are the raw materials for textiles?

- Some of the thin as onion (georgette), some light as a feather (polypropylene fabric), Kennedy more than iron (carbon fiber products), soft people like rubber (spandex fiber products).

- Q: The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Jeans shrinkage is generally 15% to 40%. Look at the thickness of the fabric, and is not elastic, there are scrub, yeast, wash, rinse, rancid wash, and so on, different washing water has different washing steps, procedures

Send your message to us

100% SMS Nonwoven Fabric, Spunbond PP Non Woven Fabric, TNT Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords