non woven fabric with self adhesive /adhesive backed fabric/felt sticker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

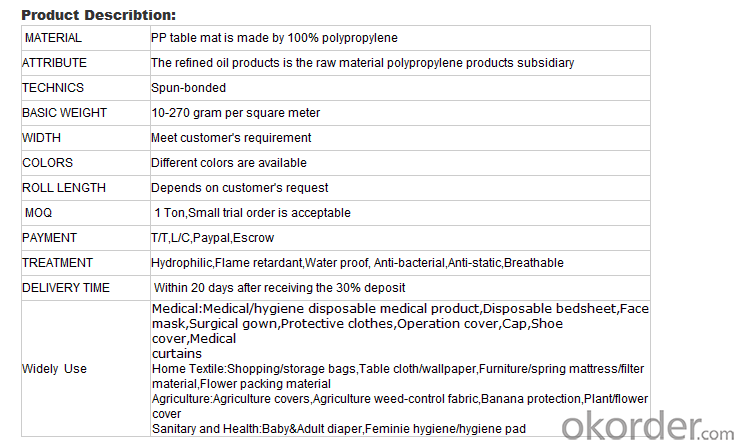

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Application of Biological Enzyme in Textile Processing

- Hemicellulase, ligninase in the textile processing applications: natural cellulose fibers contain hemicellulose and lignin, especially linen fiber content is high, do not remove hemicellulose and lignin, extreme impact The spinnability of the fiber, through hemicellulase and ligninase treatment, can most of the removal of hemicellulose and lignin

- Q: What are the test tests for the color fastness of textiles?

- 4, resistance to saliva color fastness 5, resistant to sea color fastness 6, light color fastness 7, dry clean color fastness

- Q: What are the processes of dyeing and finishing of textiles?

- Pre-treatment, dyeing, printing, post-processing and other processes. Worsted fabric - billet - singeing - Lian Bo - wash it - Lian Bo - drying - in the inspection - cooked - cut hair - pressure light - tank steaming.

- Q: What is the anti-perspiration finishing of textiles?

- At the same time, the fabric hydrophilic surface in the hydrophilic, the corresponding waterproof surface can not see the watermark. At present in the knitted fabric on the anti-perspiration finishing more mature, in the weight of the lower woven fabrics, especially light-colored anti-perspiration effect is not particularly ideal

- Q: Processing of textiles, processed products were detected formaldehyde exceeded, how to deal with

- First look at how much formaldehyde you exceeded. General formaldehyde in the national regulations have three limits: 1, infant supplies (36 months) shall not exceed 20PPM,

- Q: Performance requirements for textile fibers

- The abrasion resistance of the fiber is closely related to the fastness of its textile products. The wear and tear of the pros and cons is the performance of clothing with fabric is an important indicator.

- Q: Textile enterprises to operate the project: processing and production are different?

- Processing and production are different: the former is commissioned by the commissioned by the production, that is processed products are oriented, and sometimes the commission will also provide or specify the raw materials

- Q: DTY FDY POY What are the textile raw materials?

- FDY: full stretch silk. Full name: FULL DRAW YARN. The synthetic filament filaments were further prepared by spinning. The fibers have been fully stretched and can be used directly for textile processing.

- Q: The meaning of the following terms in the textile industry: fabric, processing number, genuine number.

- Shrink the fabric mainly refers to cotton, linen, silk, such as natural fabrics. The shrinkage rate is related to its own fiber, but also to its tightness.

- Q: What kind of textile is China's export to the United States?

- I export the main varieties of the US market: diversified woven garments (accounting for about 45%), coat clothing (35%), serialized textile products (about 20%) three major varieties

Send your message to us

non woven fabric with self adhesive /adhesive backed fabric/felt sticker

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords