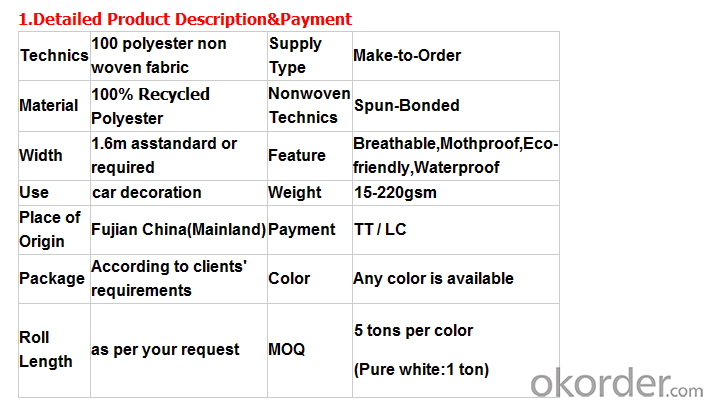

100 polyester non woven fabric for car decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What are the test tests for the color fastness of textiles?

- 8, perspiration color fastness 9, dry hot color fastness 10, heat pressure color fastness 11, resistance to water fastness 12, color fastness to brush

- Q: What kind of fiber can be used as textile fiber

- Can be used as textile fibers with natural fibers and chemical fibers. 1, natural fiber source is divided into plant fiber and animal fiber, plant fiber, plant fiber is natural cellulose fiber

- Q: Development of Textile Fibers.

- From the domestic economic environment, domestic demand will become an important driving force for industry growth. At present, about 80% of Chinese textile consumption in the country. With the sustained and rapid growth of the domestic economy, the stability of residents' income will boost the further development of the domestic market.

- Q: What is the "gold and silver wire" used in the textile industry?

- Gold and silver: that is, the physical method will be coated with color PET polyester film cut into very fine wire. Through the polyester film or nylon film plating method to make the surface coated with a layer of aluminum or silver, and then according to the textile needs to be processed into different width of the wire

- Q: Processing of textiles, processed products were detected formaldehyde exceeded, how to deal with

- Direct contact with the skin of textiles, not more than 75PPM; 3, non-direct contact with skin textiles, not more than 300PPM;

- Q: What is the purpose of using detergent in the textile industry?

- Textiles in the storage and transportation process is also easy to stained debris, dust and other impurities, but also to remove the dye.

- Q: What causes the loss of textile enterprises

- Raw material costs rise, seasonal strong, large inventories, small businesses prone to cash flow difficulties, and now the financial crisis, capital is scarce resources

- Q: What are the knowledge and abilities of the Merchants in the textile industry?

- Therefore, the main content of the work is: to confirm the progress, to help remove the obstacles, requiring quality, verify the number of post-sale problems or transfer to other after-sales department to resolve

- Q: Classification of cotton textiles

- According to the use can be divided into clothing with textiles, decorative textiles, industrial supplies three categories;

- Q: Jiangsu Province, more than a large number of textile and garment industry

- Nantong is China's famous textile base, but also the country's 12 textile export base and one of 10 clothing export base. The textile industry is an irreplaceable pillar industry in Nantong's industrialization process and regional economic development.

Send your message to us

100 polyester non woven fabric for car decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords