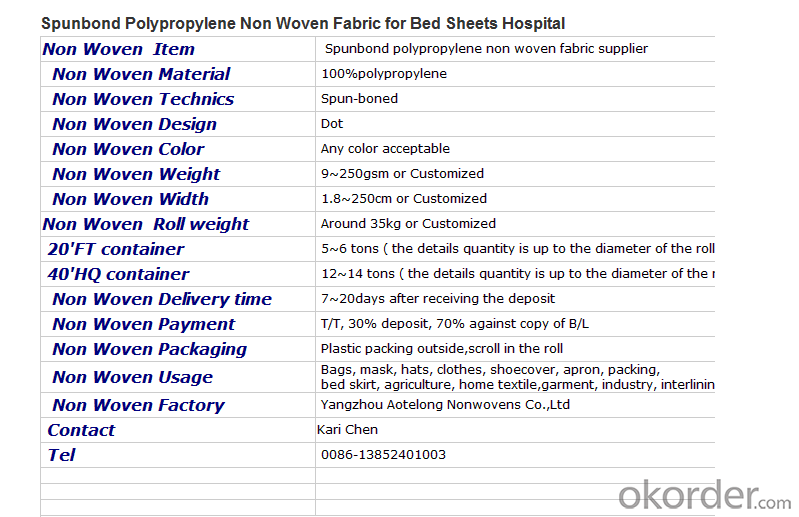

Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Listed in recent years the textile industry pollutant emissions

- The reason for the increase in industrial pollutant emissions in the first half was due to the rapid growth of GDP, leading to an increase in COD and sulfur dioxide emissions. In the first half of this year, China's GDP growth rate of 10.9%, coal production increased by 12.8%, industrial wastewater emissions increased by 3.5%.

- Q: How can paint points be removed during textile processing?

- The cross-linking agent, the adhesive is a polymer resin, they are in the air at high temperature polymerization, the coating macromolecular particle network within them

- Q: What are the common textile auxiliaries?

- Textile dyeing and finishing auxiliaries in the textile processing technology has a very important role, although the amount is not large, but in the textile processing technology has a role can not be ignored, and sometimes even have an indispensable role, summed up, textile dyeing and finishing auxiliaries In the textile products in the main play a focus on the role

- Q: Development of Textile Fibers.

- From the domestic economic environment, domestic demand will become an important driving force for industry growth. At present, about 80% of Chinese textile consumption in the country. With the sustained and rapid growth of the domestic economy, the stability of residents' income will boost the further development of the domestic market.

- Q: What is the anti-perspiration finishing of textiles?

- Many manufacturers put the anti-perspiration requirements made single-parent single defense fabric, in a sense is to complete the customer's request, but the requirements of high customers, only single-parent single effect is unable to meet the requirements, be sure to do Perspiration requirements.Hope to help you, if you want to do further understanding, see my account name and contact me

- Q: Textile printing and dyeing process which

- Dyeing long car is divided into two parts, before the car dyeing, after the car fixing color. Dyeing method according to the choice of different varieties of dyes are different, dyes are generally active, Shihlin, vulcanization, paint. They have their own advantages and disadvantages, under normal circumstances to see the color requirements, and can not replace each other.

- Q: What is a textile fabric?

- Gray cloth of the British fabric is woven after the printing and dyeing has not been processed cloth, has not done pre-treatment, dyeing / printing, finishing cloth. Industrial gray cloth again refers to the fabric or fabric

- Q: What are the classification of the textile?

- Cotton spinning silk processing linen wool chemical fiber can also be divided according to the weaving method: knitted woven nonwoven

- Q: What are the products produced by the textile mill?

- From the processing of the process, said: basically the fiber - yarn - line - cloth. Yarn is divided into weaving yarn, knitting yarn. Chemical fiber yarn is sprayed with spinneret. Cloth is divided into woven fabrics, knitted fabrics, finished dyeing and finishing yarn weaving and so on.

- Q: What is the role of textile degreasing in life?

- Clothing in the dyeing and finishing process, often encountered in the cloth oil, stains, color stains, color flowers, silicone oil spots, etc., constitute a low amount of product resources, and some even helpless repair, and in the process of processing need Use a lot of additives, so clothing is also very easy to become very oil. At this time, you need to deal with the textile degreasing agent.

Send your message to us

Spunbond Polypropylene Non Woven Fabric for Bed Sheets Hospital

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords