Eco-friendly Polypropylene Spunbond Non-woven Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

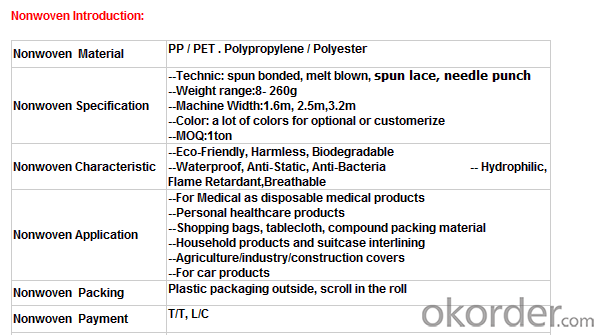

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

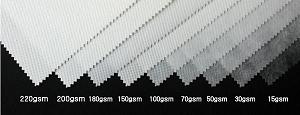

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: The weight of the textile fabric

- We as a textile fabric salesman, the general situation is this, the guests gave a piece of cloth or give a detailed specification, we need to analyze the offer. On the analysis of the fabric, this article has a lot of very detailed, and I will not say here. Fabric cost accounting, the general idea is:

- Q: What kind of fiber can be used as textile fiber

- Animal fiber, animal fiber is the animal hair or insect gland secretions obtained in the fiber. The hair from the animal hair has wool, rabbit hair, camel hair, goat hair, yak cashmere, etc .; from the animal gland secretions get fiber and so on.

- Q: Differences between textile mills and garment factories

- In order to have fabric sent to the garment factory made of clothes. Garment factory is made of various kinds of fabric clothing;

- Q: What is the difference between the nonwovens industry and the textile industry?

- Textiles are raw materials of cotton, or man-made fibers. Is made of textile machinery, no glue composition. For clothing, bedding and other uses with the human body.

- Q: The difference between double distribution and processing in textile fabrics

- Double distribution - that is, fabric fabric is where you specify, they buy, processing, and then sold to you.

- Q: What is the textile technology profession now?

- Knitting process; This course introduces the basic concepts of knitting and knitwear, weft knitting and warp knitting machine basic structure and working principle, commonly used knitted fabric weaving methods and process analysis

- Q: What is the meaning of the number of yarns used in cotton textiles?

- The fineness of the yarn (in English): refers to a pound (454 grams) of heavy cotton yarn in the provisions of moisture regain, there are several 840 yards (1 yards = 0.941 meters) long, that is, a few miles of yarn, As "a few yarn", the unit with "S" said.

- Q: What are the classification of the textile?

- Warp, warp, warp density - the length of the fabric; the yarn is called the warp; the number of yarns in the 1 inch yarn is the density (warp density);

- Q: Why can the oil industry be used as raw materials for the textile industry?

- Commonly used textile industry raw materials are: polyester: polystyrene dicarboxylate; nylon: polyamide fiber; polypropylene: acrylic fiber; acrylic: polyacrylonitrile fiber; polyvinyl chloride: polyvinyl chloride; vinylon: polyvinyl alcohol shrink Aldehyde fiber; aramid: poly (p-phenylene terephthalamide).

- Q: The Development of Textile Industry

- The global textile industry market uncertainty is increasing, which with the global credit crisis and the United States, the EU economic growth slowdown in the trend will bring impact on the clothing retail industry.

Send your message to us

Eco-friendly Polypropylene Spunbond Non-woven Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords