Non woven Fabrics for Baby Wipe Raw Material, 30-100gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

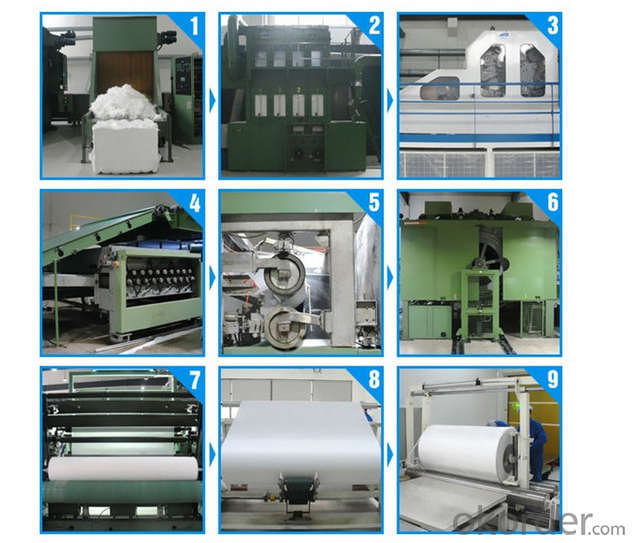

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

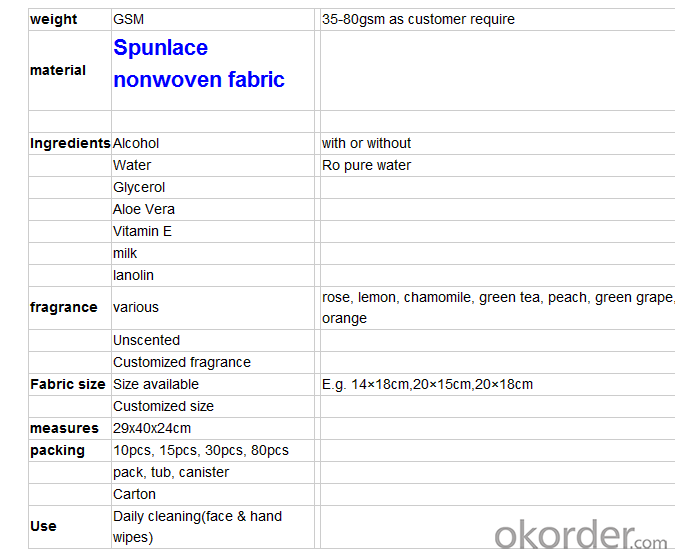

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: Listed in recent years the textile industry pollutant emissions

- From the first half of this year and the third quarter of China's major pollutant emissions, industrial wastewater emissions of 120.4 billion tons, an increase of 2.4%; COD emissions of 6.896 million tons, an increase of 3.7%; sulfur dioxide Emissions of 12.746 million tons, an increase of 4.2%.

- Q: What kind of fiber can be used as textile fiber

- The main chemical composition of animal fiber is protein, it is also known as protein fiber. 2, chemical fiber, chemical fiber is processed by chemical processing and fiber. Can be divided into man-made fibers (regenerated fiber), synthetic fibers and inorganic fibers. Artificial fiber is also called regenerated fiber. The man-made fiber is made of natural fiber or protein fiber, such as wood, sugar cane, reed, soybean protein fiber and other fiber raw materials that lose the value of textile processing.

- Q: Lin is what kind of textile

- For jacquard fabric, can not be hard brush scrubbing, to prevent yarn breakage. 3, cotton fabric with good physical and chemical properties, but also should not be soaked in the washing solution for too long, exposure time can not be too long to prevent the destruction of color. 4, cotton fabric easy to float color, washing to prevent string dyeing and pick color, affecting the fabric appearance.

- Q: Differences between textile mills and garment factories

- In order to have fabric sent to the garment factory made of clothes. Garment factory is made of various kinds of fabric clothing;

- Q: What is the number of raw materials for textile enterprises?

- Cost calculation According to the comprehensive cost of the slurry, and then by the sizing rate to plan the need to consume the total amount of slurry to determine the cost of another sizing energy consumption is also a great cost.

- Q: Application of Biological Enzyme in Textile Processing

- Hemicellulase, ligninase in the textile processing applications: natural cellulose fibers contain hemicellulose and lignin, especially linen fiber content is high, do not remove hemicellulose and lignin

- Q: Analysis of import and export of textile

- In recent years, China's textile industry, the overall size of the overall growth rate showed a gradual slowdown trend. In 2013, China's fiber processing volume reached 48.5 million tons, compared with 2010 increased by 17.4%, an average annual growth of 5.5%, while the first decade of the century, that is, 2001 to 2010, the average annual growth rate of 11.7%

- Q: "Textile color standard system"

- Color fastness and poor, directly related to the health and safety of the human body, poor color fastness in the process of wearing, run into the rain, sweat will cause the fabric off the paint off,

- Q: How to do the textile warehouse damp

- The damp air is like a fog that, in the erosion of the textile mill's warehouses, creates a great deal of damage to the textile made of plant fibers. In recent years, the domestic textile industry has been sluggish, if the wet to the product, which can not be forgiven.

- Q: What kind of textile is China's export to the United States?

- China's exports to the United States of textile clothing, clothing accounted for about 70%, about 30% of textiles. In 2006, China's textile and garment exports to the United States reached 21.9 billion US dollars, an increase of 18%, of which clothing was 16.3 billion US dollars, accounting for 74% of all exports to the United States; textiles for 5.6 billion US dollars, accounting for 26% The

Send your message to us

Non woven Fabrics for Baby Wipe Raw Material, 30-100gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords