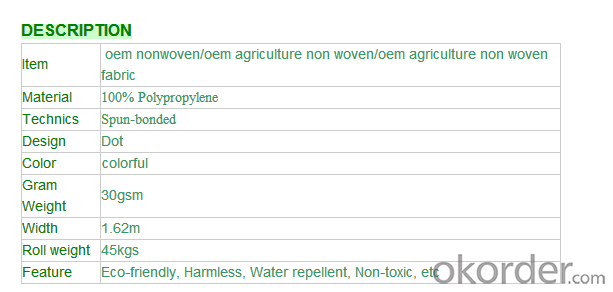

oem nonwoven/oem agriculture non woven/oem agriculture non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

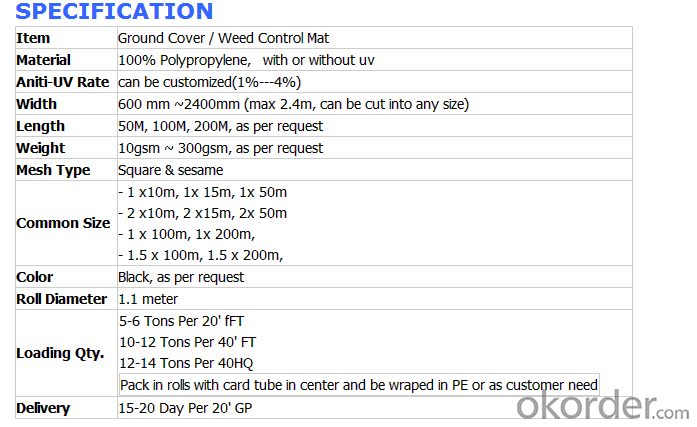

PP non woven weed control mat is made of environmentally friendly raw materials, pp spunbond nonwoven fabric. It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.

PP non woven weed control mat is made of environmentally friendly raw materials, pp spunbond nonwoven fabric. It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.

They are permeable fabrics, which allow air, water and nutrients to pass through, and designed to block out the sun to reduce photosynthesis and stop weed growth.

The use of landscaping fabrics has become extremely popular in recent years for many reasons:

1. Leisure time is maximised - the need for weeding and on-going maintenance is minimised

2. Environmentally friendly - no need for chemical based weed killers

3. Promotes healthier plants - it allows the soil to breath and water to permeate

We offer different types of weed control fabrics to suit all applications and budgets.

1. Available in a range of sizes & materials to suit various applications from small to large landscaping projects, in both commercial and domestic situations.

2. All our landscape fabrics are UV stabilised

3. Ideal for use under paths, patios, decking, paving, bark mulch, gravel etc.

FEATURES:

1. Weed suppressant and drainage control landscaping fabric

2. Spun bonded non-woven fabric – will not fray when cut

3. Easy to use

4. Environmentally friendly

5. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

6. Good alternative to Plantex® where cost is a factor

7. UV Stabilised

8. Reduces the level of watering required due to the slower rate of water evaporation

FUNCTION:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

APPLICATIONS:

1. Weed block for landscaped garden beds

2. Permeable liners for planters (stops soil erosion)

3. Weed control under wooden decking

4. Geotextile for separating aggregate / soils under walkway blocks or bricks

5. Assists in preventing paving from settling unevenly

6. Landscape fabric prevents soil erosion

Health - Hygiene & Medical

Surgical Gowns

Gloves

Face Masks

Foot covers

Diapers

Caps

Bedsheets

Curtains

Pillow Covers

Slippers

Packaging

Sleeping Bags

Tarpaulins

Tents

Artificial Leather

Bags for Rice/Sugar etc.

Luggage

Vacuum Cleaner Bags

Tea and Coffee Bags

Buff Pads

Shopping Bags

Agriculture

Crop Covers

Turf Protections

Nursery Over wintering

Weed Control Fabrics

Root Bags

Containers

Capillary Matting

Other types of covers

Furniture Upholstery

Roofing and Tile Underlayment

Acoustical Ceilings

Insulation

House wrap

Pipe wrap

Sofa and Mattress Lining

Shoes & Garments

Coveralls

Pillow cases

Airline Headrests

Interlinings

Clothing and Glove insulation

Bra and Shoulder Padding

ADVANTAGES:

1. Lower labour costs as no weeding maintenance for years;

2. Water seeps through and can conserve soil moisture for improved growing conditions;

3. Air escapes – humidity rises through the mat for a more controlled growing environment;

4. Increase crop yields close to 25% due to improved growing conditions and absence of water stress and competition of nutrients absorption from weeds;

5. Minimises bacteria and fungus problems especially Algae;

6. Strong, woven construction or pressed fibre sheet resists tears and punctures;

7. Resistant to mildew, rot, water, sunlight and most of the agricultural chemicals

8. Fertilizer is applied on the mat, thus helping the owner or estate manager to monitor the progress of manuring;

9. Prevents soil erosion or leaching of soil nutrients or fertilizers applied;

10. Environmental friendly.

- Q:Sponges are plastic or textiles

- The foaming resin, the foaming aid and the binder resin (the finished product having adhesiveness) are mixed together; For foam processing. 80 parts of ethylene vinyl acetate (EVA), 20 parts of APAO PT 3385, 20 parts of azodicarbonamide, 9 parts of CaCO and 0.6 part of dicumyl peroxide were mixed together and placed in a mold, And mechanical resistance to break the hole, you can get foam sponge. The density (d) is 0.028 g / cm, and the compression hardness of 25% is 1.9 KPa.

- Q:What are the test tests for the color fastness of textiles?

- 4, resistance to saliva color fastness 5, resistant to sea color fastness 6, light color fastness 7, dry clean color fastness

- Q:Analysis of import and export of textile

- From 2011 to 2013, the main business income of textile enterprises above designated size increased by 12% on average, down 6.8 percentage points over the previous decade; the total assets increased by 9% annually, down by 3.1 percentage points over the previous decade

- Q:Are hats a class of textile and apparel products?

- All year round seems to generally only winter hat, hat should belong to the textile and apparel products bar. Jewelery is available all year round.

- Q:"Textile color standard system"

- Color fastness refers to the resistance of the color of the textile to various effects during processing and use. The fastness rating was determined according to the discoloration of the sample and the staining of the unstained fabric. Textile color fastness test is a textile internal quality testing in a routine testing project

- Q:Why can the oil industry be used as raw materials for the textile industry?

- Textile raw materials is taken from the general terms of spinning and weaving, but with the textile knowledge system and the continuous development and improvement of the discipline system, especially non-woven textile materials and three-dimensional composite weaving and other technologies, the textile is now not only traditional Hand-spinning and weaving, including non-woven technology, modern three-dimensional weaving technology, modern electrostatic nano-network technology, so modern textile is a fiber or fiber aggregate multi-scale structure processing technology [1-2 ]

- Q:China is now optimistic about which one of the textile industry

- Filtration with textile processing technology and development and application of acupuncture, spunlace, spunbond and other non-woven and woven high efficiency filter with textile materials and products of complete sets of processing technology and industrial applications

- Q:How does the chemical composition of the textile be analyzed?

- Cotton, hemp, wool (sheep, rabbit), silk, polyester, viscose, spandex, nylon, cashmere and so on

- Q:How to grow in the textile industry and have their own customers

- Third, the loss of each process. Like 1000KG raw cotton, spinning to wear about 10%, dyeing yarn to wear about 8%, weaving to about 2% loss, finishing if the dyeing loss to about 8%

- Q:What is the "gold and silver wire" used in the textile industry?

- Gold and silver silk "material is mainly aluminum, plus the required color of the paint

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

oem nonwoven/oem agriculture non woven/oem agriculture non woven fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords