Armstrong Fiberglass Ceiling Panels - Hot Sale for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale fiberglass ceiling tiles for decration

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

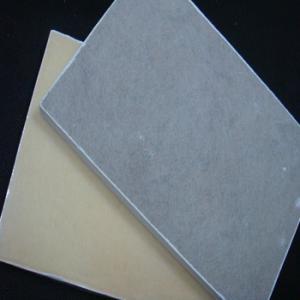

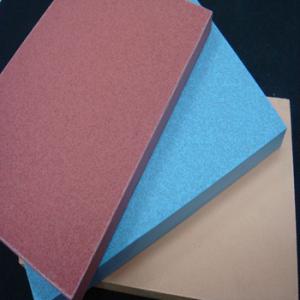

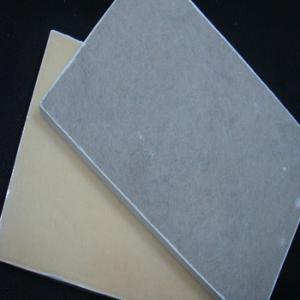

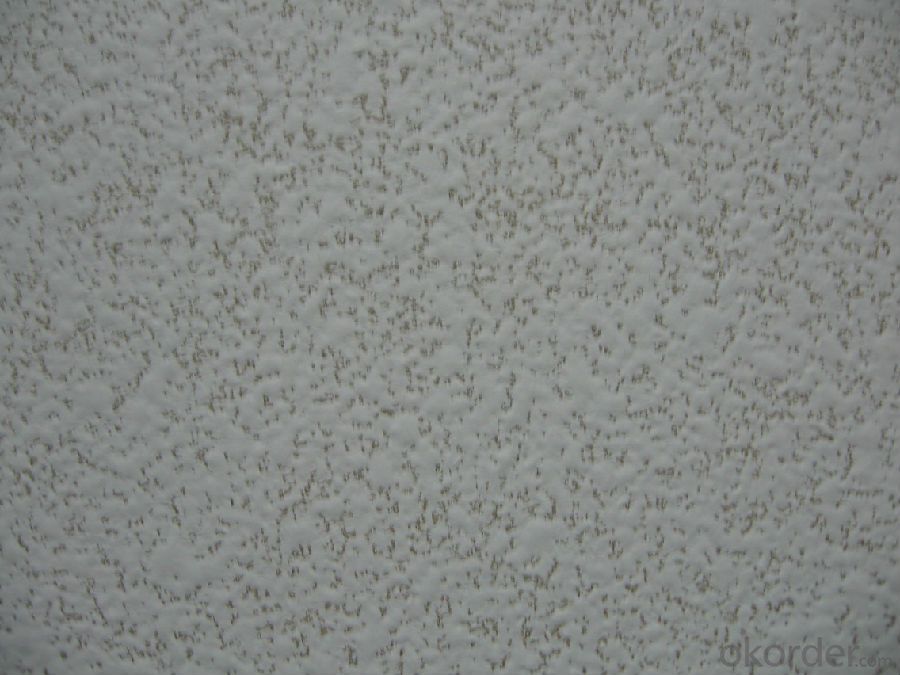

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

Black spray White spray

Mix Acoustic White painted

Hot sale fiberglass ceiling tiles for decration

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

Hot sale fiberglass ceiling tiles for decration

- Q: The main purpose of glass fiber

- The roving is made of parallel raw wire or parallel monofilament. Twistless roving according to the glass composition can be divided into: alkali-free glass roving and alkali glass roving. Production of glass roving used glass fiber diameter from 12 ~ 23μm. The number of roving rovings is from 150 to 9600 (tex). The roving can be used directly in some composite material forming methods, such as winding and pultrusion processes, which can also be woven into a roving fabric because of their uniform tension and further chopped rovings for some applications The

- Q: If you were a single woman with no man around, how would you fix a hole in the ceiling from water damage? And the roof? On a budget. Is this possible for a small woman to do this job by herself? Can someone give me step by step instructions? Photo of the damage attatched.

- I would repair it. It is not terribly difficult or costly - but your circumstance is complicated by the texture on the ceiling. You would need to purchase some lightweight joint compound, some fiberglass reinforcing mesh or tape, a couple of inexpensive plastic spackling knives (and you will need either a step-ladder or some other stable platform to work from. You will clean out the damaged area and remove all loose materials. Then use a knife to spread some joint compound in the hole, not too much but enough to cover everything with a thin coat. Spread the reinforcing material over this and add a small amount more compound. Smooth this as best you can with a knife. Allow to cure overnight. Repeat with thin coats of compound only until smooth. Sand lightly to remove tool marks. Now you have as smooth area in a textured area. There are texture-sprays-in-a-can that you can try, or you can just leave it smooth, Paint. Done. It takes some time, and you will learn as you go - so don't expect perfection right away. Good luck with it.

- Q: Fiberglass sound-absorbing ceiling features

- (GB9624-997) anti-tide anti-sag: in the room ~ temperature 40QCIX summer relative humidity is 90%, the size of the stability

- Q: We just had our first child, and his room is right above the garage. It is noticebly colder in his room, especially the floor. I used the plastic window kits and that helped, however, the floor is still extremely cold and I would like to at least check the insulation in the garage ceiling. Right now there is drywall on the ceiling, but I have no qualms about ripping it down, not real worried what it looks like. What should I look for...I believe there is very old (50 years) fiberglass insulation but i'm not 100% sure. If there is the old insulation there...should I look to replace it? If so, with what R value...Is this a project that someone without specific experience in the field could complete? I'm pretty handy but certainly not a pro. I'm not worried at all how it looks in the garage.

- The joists are probably 2X8 in which case you can use an R30 fiberglass batt. I would use unfaced and then staple up plastic. That will provide a better moisture and draft protection than the faced insulation would.

- Q: Our basement bedroom does not have insulation in ceiling between joists but it is possible to insulate from another area that is not finished but I would have to use the insulation which is blown in between the joists. Is this a good insulation and is it practical to do for noise reduction? Otherwise, we would have to tear out the ceiling in the bedroom and use the fiberglass insulation. Do you have any other ideas or suggestions for noise reduction? This is a new home.

- You wouldn't be able to poke in Fiberglass that's for sure. Also it doesn't absorb that much sound anyway. Blown in wouldn't help that much either (after a couple of years it settles anyway). You appear to be looking for sound proofing. There are many different kinds of ceiling tile out there and you should check out as to which works best and include wall material too as just the ceiling alone may not do the job well enough plus you would need to do the door too. (There isn't much you can do about the windows unless you block them). Best of all check out a building materials store or someone who has done something similar. Good luck!

- Q: How to design a small living room look good.

- You can go and see the exchange space.

- Q: I had the roof replaced last summer, but havent had the energy to get up there and take down the ceiling tiles and the fiberglass insulation. I started removing it a section at a time a week ago, and wow! What a mess!. Gravel is falling down on my head and the insulation and tiles are dry now, but its still hard to pull them out. Should I be wearing a mask? Is there anything in the old dried out insulation and ceiling tiles that I should cover my nose? Its making a really big mess, so any suggestions will be helpful.

- Well, the masks are cheap, so why take a chance. I wouldn't want to breathe fiberglass. Personally I would wear an old cap, and a throw away mask. Cheap at any hardware store or some of the dollar stores. There might be mold up in there also, if it was wet. Not good to breathe mold spores.

- Q: What is zero energy building

- It seems that there is no such thing, and now only a single energy "zero energy", such as the use of solar energy or wind power to replace the power plant to send electricity, to achieve electricity "zero energy"; the use of rain after filtration into the water as a wash Rinse with the "water zero energy consumption"

- Q: I have hanged the drywalls on both the ceiling and walls. My questions is how should I tape the joints between the ceiling and walls? Should I use a regular paper tape, a fiberglass mesh or a paper corner bead (inside corner)?

- I do Sheetrock repairs in apartments and houses. I have found that the paper tape works better in this application. after you put the mud in the joints tear of a piece of tape to cover the area you feel comfortable with. Usually five or six feet. Fold the tape in half. After you fold it it will look like a apiece of angle iron. then take the putty knife and push it in place as you press in in place be sure an keep it pushed into the joint so you do not leave a bubble. Then feather the mud as you go .Add another piece overlapping each piece slightly. When you get to the end butt the joints in the corner. Be sure and look back and make sure it stays tight in the groove. Good luck

- Q: Large area gypsum board light with no blockboard solid

- House interior wallboard, ceiling. All the panels are inside the gypsum board. Generally 12 mm thick, the surface is paper. There are very few glass fibers in the middle. It is fireproof moisture absorption sound insulation, is very good building materials. Used for decades to the present.

Send your message to us

Armstrong Fiberglass Ceiling Panels - Hot Sale for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords