Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled SUP10 Spring Steel Bar,Round Bar

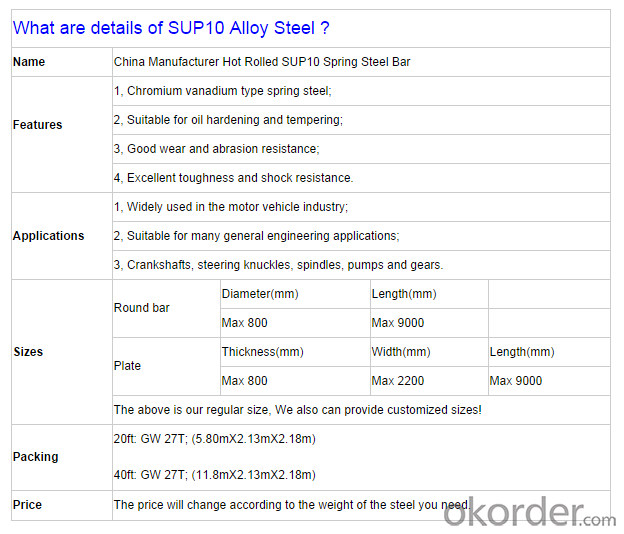

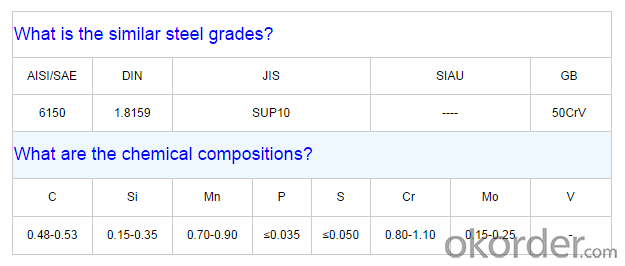

Product information:

Product show

Workshop show

Our service:

- Q: What are the advantages of using titanium-alloy steel round bars?

- Titanium-alloy steel round bars offer numerous benefits: 1. Exceptional strength: These round bars possess an impressive strength-to-weight ratio, making them perfect for applications that prioritize strength. They can withstand heavy loads and resist deformation due to their high tensile strength. 2. Impressive corrosion resistance: Even in highly corrosive environments, titanium-alloy steel round bars exhibit excellent resistance to corrosion. This quality makes them well-suited for industries like marine, aerospace, and chemicals, where exposure to saltwater or chemicals is common. 3. Lightweight nature: In comparison to other metal alloys, titanium-alloy steel round bars are comparatively lightweight. This characteristic makes them highly advantageous in industries like aerospace and automotive, where reducing weight is crucial. It enables better fuel efficiency and increased payload capacity. 4. Resilience to high temperatures: Titanium-alloy steel round bars maintain their structural integrity even when exposed to high temperatures. This quality makes them ideal for applications in high-temperature environments, such as power generation and the oil and gas industries. 5. Biocompatibility: Titanium is biocompatible, meaning it is well-tolerated by the human body and does not cause adverse reactions. This makes titanium-alloy steel round bars suitable for medical implants like orthopedic implants and dental fixtures, where biocompatibility is critical. 6. Exceptional fatigue resistance: Titanium-alloy steel round bars exhibit outstanding resistance to fatigue, enabling them to endure repeated loading and unloading without experiencing fatigue failure. This makes them ideal for applications requiring long-term durability, such as structural components and machinery. Overall, the advantages of titanium-alloy steel round bars encompass their high strength, corrosion resistance, lightweight nature, resilience to high temperatures, biocompatibility, and exceptional fatigue resistance. These properties make them a versatile choice for various industries, including aerospace, automotive, medical, and petrochemical sectors.

- Q: What is the maximum length of a steel round bar?

- The length of a steel round bar can vary depending on several factors, including the bar's diameter, the manufacturing capabilities of the steel supplier, and transportation restrictions. Typically, steel round bars are made in standard lengths ranging from 6 to 12 meters (20 to 40 feet). However, it is possible to create longer bars through specialized processes or by combining multiple bars using welding techniques. In certain cases, it is possible to order custom-made steel round bars that exceed standard lengths, but this would necessitate making specific arrangements with the supplier and considering logistical and handling aspects during transportation. Ultimately, the maximum length of a steel round bar is determined by practical limitations and the specific requirements of the project or application.

- Q: What are the advantages of using steel round bars compared to other materials?

- There are several advantages to using steel round bars compared to other materials. Firstly, steel is known for its strength and durability, making it ideal for heavy-duty applications. It can withstand high temperatures, pressure, and heavy loads without warping or breaking. Secondly, steel round bars are highly versatile and can be easily machined, welded, and formed into various shapes and sizes, making them suitable for a wide range of applications. Additionally, steel is a cost-effective option as it provides excellent long-term value due to its durability and low maintenance requirements. Lastly, steel is a sustainable and environmentally friendly material as it can be recycled and reused indefinitely without losing its properties.

- Q: How are steel round bars used in the manufacturing of lifting equipment?

- Steel round bars are commonly used in the manufacturing of lifting equipment due to their strength, durability, and versatility. These bars are typically made from high-quality steel alloys, such as carbon steel or alloy steel, which provide the necessary strength and toughness required for lifting heavy loads. In the manufacturing process, steel round bars are often used as the main structural component of lifting equipment such as cranes, hoists, and lifting hooks. They are utilized to create the frame and support structures that provide the necessary stability and load-bearing capacity. Steel round bars are also employed to fabricate various lifting components, such as shafts, axles, and pins, which play a crucial role in the proper functioning of lifting equipment. These components are designed to withstand high levels of stress and strain, and the use of steel round bars ensures that they can handle heavy loads without deformation or failure. Additionally, steel round bars are frequently utilized to manufacture lifting hooks and chains. Lifting hooks are crucial for attaching the load to the lifting equipment, while chains are used to secure and lift the load. Steel round bars provide the necessary strength and rigidity to handle the weight of the load, ensuring safe and efficient lifting operations. Furthermore, steel round bars can be machined, forged, or heat-treated to achieve specific mechanical properties required for lifting equipment manufacturing. This allows manufacturers to tailor the characteristics of the bars to meet the specific requirements of different lifting applications, such as the ability to withstand high temperatures or resist corrosion. Overall, steel round bars are an essential component in the manufacturing of lifting equipment. Their strength, durability, and versatility make them ideal for creating the structural frames, support structures, and lifting components necessary for safe and efficient lifting operations.

- Q: What are the factors to consider when selecting a steel round bar?

- When selecting a steel round bar, there are several factors that should be taken into consideration. Firstly, it is important to consider the grade of steel. Different grades of steel have varying properties and strengths, so the specific application and requirements should be evaluated. For example, if high corrosion resistance is needed, stainless steel grades like 304 or 316 may be suitable, whereas for structural applications, carbon steel grades like A36 or 1018 may be more appropriate. Secondly, the dimensions and size of the round bar should be considered. This includes the diameter, length, and tolerance requirements. The size should be chosen based on the specific application, load-bearing capacity, and the available space for installation. Thirdly, the surface finish and condition of the round bar should be assessed. This includes factors such as surface roughness, straightness, and any surface defects. The surface finish should be selected based on the desired aesthetics, functional requirements, and the manufacturing process. Another important factor is the availability and cost of the steel round bar. It is crucial to consider the availability of the desired grade and size from suppliers, as well as the associated cost. It is advisable to compare prices from different suppliers to ensure the best value for money. Furthermore, the required mechanical properties of the steel round bar should be evaluated. This includes factors such as tensile strength, yield strength, hardness, and ductility. The mechanical properties should align with the intended application and load-bearing requirements. Lastly, it is essential to consider any additional requirements or certifications that may be needed. This could include compliance with specific industry standards (e.g., ASTM, ISO), certifications (e.g., RoHS, REACH), or specific testing requirements (e.g., ultrasonic testing, impact testing). In conclusion, when selecting a steel round bar, it is important to consider the grade, dimensions, surface finish, availability, cost, mechanical properties, and any additional requirements. Taking into account these factors will help ensure that the steel round bar chosen is suitable for the intended application and meets all necessary specifications.

- Q: What are the advantages of using aluminum-silicon alloy steel round bars?

- There are several advantages of using aluminum-silicon alloy steel round bars: 1. Lightweight: Aluminum is a lightweight material, and when alloyed with silicon, it further enhances the strength-to-weight ratio, making the round bars lighter and easier to handle. This is particularly beneficial in applications where weight reduction is crucial, such as aerospace and automotive industries. 2. High strength: Aluminum-silicon alloy steel round bars possess excellent mechanical properties, including high tensile strength and good yield strength. This allows them to withstand heavy loads and provide structural integrity in various applications. 3. Corrosion resistance: Aluminum-silicon alloy steel round bars offer good corrosion resistance, especially in environments where moisture or chemicals are present. This makes them suitable for applications where exposure to harsh conditions or corrosive substances is a concern. 4. Thermal conductivity: Aluminum-silicon alloy steel round bars have excellent thermal conductivity, which allows for efficient heat transfer. This property is particularly advantageous in industries such as heat exchangers, where effective thermal management is essential. 5. Machinability: Aluminum-silicon alloy steel round bars are relatively easy to machine, allowing for precise shaping and forming. This makes them ideal for applications where intricate designs or specific dimensions are required. 6. Cost-effectiveness: Compared to other materials, aluminum-silicon alloy steel round bars offer a cost-effective solution due to their relatively low production and maintenance costs. This makes them a popular choice in various industries, including construction, automotive, and manufacturing. 7. Recyclability: Aluminum-silicon alloy steel round bars are highly recyclable, which is crucial in today's environmentally conscious world. Recycling aluminum-silicon alloys requires significantly less energy compared to primary production, making them a sustainable choice. Overall, the advantages of using aluminum-silicon alloy steel round bars include their lightweight nature, high strength, corrosion resistance, thermal conductivity, machinability, cost-effectiveness, and recyclability. These properties make them a versatile material for a wide range of applications across different industries.

- Q: What are the different types of steel used in manufacturing round bars?

- There are several different types of steel that are commonly used in the manufacturing of round bars. Some of the most common types include: 1. Carbon Steel: This is the most common type of steel used in manufacturing round bars. It is made up primarily of iron and carbon, and is known for its strength and durability. Carbon steel round bars are used in a wide range of applications, including construction, automotive, and machinery. 2. Alloy Steel: Alloy steel is made by adding various elements to carbon steel, such as manganese, nickel, chromium, and molybdenum. These additional elements enhance the strength and hardness of the steel, making it ideal for applications that require high strength and resistance to wear and tear. 3. Stainless Steel: Stainless steel is a type of alloy steel that contains a minimum of 10.5% chromium. This high chromium content gives stainless steel its unique corrosion resistance properties, making it suitable for applications where exposure to moisture or chemicals is a concern. Stainless steel round bars are commonly used in the manufacturing of kitchen utensils, medical equipment, and automotive parts. 4. Tool Steel: Tool steel is a type of alloy steel that is specifically designed to have high hardness, wear resistance, and heat resistance. It is commonly used in the manufacturing of cutting tools, dies, and molds. Tool steel round bars are typically made from high-carbon steel with additional elements like tungsten, vanadium, or cobalt. 5. Bearing Steel: Bearing steel is a type of alloy steel that is specifically designed for use in bearing applications. It is characterized by its high hardness, wear resistance, and fatigue strength. Bearing steel round bars are commonly used in the manufacturing of bearings for various industries, including automotive, aerospace, and industrial machinery. These are just a few examples of the different types of steel used in the manufacturing of round bars. The specific type of steel chosen will depend on the desired properties and requirements of the application.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in the manufacturing of bicycle frames and handlebars due to its strength, durability, and ability to absorb vibrations. Steel round bars provide the necessary structural integrity and rigidity required for these components, making them suitable for use in bicycle frames and handlebars.

- Q: Can steel round bars be used for making electrical system components?

- Yes, steel round bars can be used for making electrical system components. Steel is a versatile material that has many applications in various industries, including electrical engineering. While other materials like copper are commonly used for electrical components due to their high electrical conductivity, steel can still be utilized for certain parts of an electrical system. Steel round bars can be used to manufacture structural components, supports, enclosures, or mounting brackets for electrical devices. Additionally, steel's durability, strength, and resistance to corrosion make it a suitable choice for electrical system components that require robust construction or protection from environmental factors. However, it is important to note that steel is not a good conductor of electricity compared to materials like copper or aluminum, so it may not be suitable for components that require high electrical conductivity.

- Q: What is the typical hardness of a steel round bar?

- The typical hardness of a steel round bar can vary depending on the specific grade and heat treatment it has undergone. However, in general, steel round bars have a hardness ranging from 100 to 300 on the Brinell hardness scale. This scale measures the resistance of a material to indentation and is commonly used to assess the hardness of metals. It is important to note that different applications may require different levels of hardness, and steel round bars can be customized to meet specific requirements through various heat treatment processes such as quenching and tempering.

Send your message to us

Hot Rolled SUP10 Spring Steel Bar,Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords