Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Steel Flat Bar

Details of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10Steel Flat Bar

Name | Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | Sup6_Sup7_Sup9_SUP9A_Sup10 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Chemical Composition of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

| Chemical Compositional Chart | ||||||||

| Standard | Material/ Grade | C | SI | Mn | Cr | V | P | s |

| ≤ | ||||||||

| DIN 17221 | 60SiCr7 | 0.57-0.65 | 1.50-1.80 | 0.70-1.00 | 0.20-0.40 | 0.03 | 0.03 | |

| 55Cr3 | 0.52-0.59 | ≤0.40 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 60Cr3 | 0.56-0.64 | 0.17-0.37 | 0.70-1.00 | 0.70-1.00 | 0.025 | 0.025 | ||

| 50CrV4 | 0.47-0.55 | 0.15-0.40 | 0.70-1.00 | 0.70-1.10 | 0.10-0.20 | 0.03 | 0.03 | |

| JIS G4801 | SUP6 | 0.55-0.65 | 1.50-1.80 | 0.70-1.00 | 0.035 | 0.035 | ||

| SUP7 | 0.55-0.65 | 1.80-2.20 | 0.70-1.00 | 0.035 | 0.035 | |||

| SUP9 | 0.52-0.60 | 0.15-0.35 | 0.65-0.95 | 0.65-0.95 | 0.03 | 0.03 | ||

| SUP9A | 0.56-0.64 | 0.15-0.35 | 0.70-1.00 | 0.70-1.00 | 0.03 | 0.03 | ||

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.80-1.10 | 0.15-0.25 | 0.03 | 0.03 | |

| SAE J1268 | 9260/H | 0.55-0.65 | 0.70-1.20 | 0.65-1.10 | ≤0.2 | 0.04 | 0.03 | |

| 5155 | 0.50-0.60 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.04 | 0.03 | ||

| 5160/H | 0.55-0.65 | 0.15-0.35 | 0.65-1.10 | 0.60-1.00 | 0.04 | 0.03 | ||

| 6150 | 0.47-0.54 | 0.15-0.35 | 0.60-1.00 | 0.75-1.20 | ≤0.15 | 0.04 | 0.03 | |

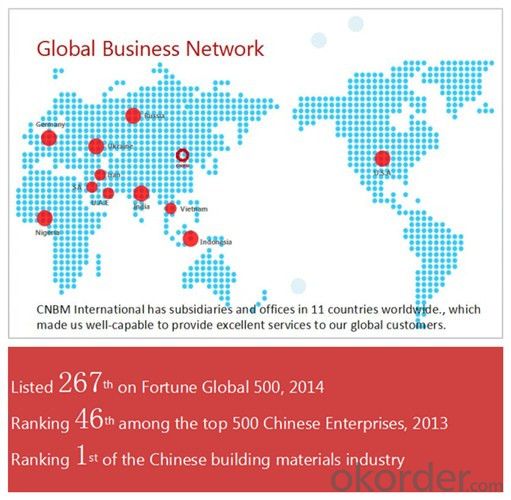

CNBM Introduction of Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar Supplier

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

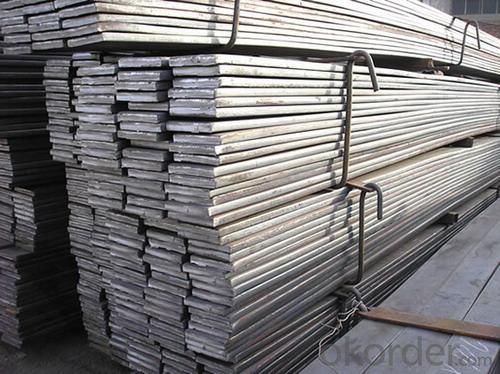

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be cast?

- Yes, special steel can be cast.

- Q: What are the requirements for special steel used in pharmaceutical manufacturing?

- The requirements for special steel used in pharmaceutical manufacturing include high corrosion resistance, excellent cleanliness and hygiene, resistance to high temperatures and chemicals, and compliance with strict regulatory standards such as Good Manufacturing Practices (GMP). Additionally, the steel must be able to maintain the integrity of the pharmaceutical products, ensuring their purity and preventing contamination.

- Q: How does stainless steel contribute to the production of medical implants?

- Stainless steel contributes to the production of medical implants by providing a highly durable and corrosion-resistant material that is compatible with the human body. It is used in various implants such as joint replacements, dental implants, and surgical instruments due to its strength, biocompatibility, and ability to withstand sterilization processes.

- Q: How does special steel perform in impact loading conditions?

- Special steel is known for its exceptional toughness and strength, making it highly effective in impact loading conditions. It can withstand high levels of force and absorb energy, resulting in minimal deformation or damage. This makes special steel a reliable choice for applications where impact resistance is crucial, such as in construction, automotive, and aerospace industries.

- Q: How is case-hardening steel used in the manufacturing of gears?

- Case-hardening steel is used in the manufacturing of gears to enhance their durability and strength. The process involves heating the steel to a high temperature and then rapidly cooling it to create a hard outer layer, known as the case, while maintaining a relatively softer core. This hardened surface provides resistance to wear, abrasion, and fatigue, allowing the gears to withstand heavy loads and prolonged use. Additionally, case-hardening steel also improves the gear's ability to withstand impact and retain its shape, ensuring efficient and reliable performance in various mechanical applications.

- Q: How does the alloying elements affect the properties of special steel?

- Alloying elements have a significant impact on the properties of special steel. By adding specific elements in controlled quantities, the strength, hardness, corrosion resistance, and other desirable properties of steel can be enhanced. For example, the addition of chromium can improve stainless steel's corrosion resistance, while molybdenum can enhance its strength and toughness. Similarly, elements like nickel, vanadium, and tungsten can influence various properties of special steel, making it suitable for specific applications in industries such as automotive, aerospace, and construction. Overall, alloying elements play a crucial role in tailoring the properties of special steel to meet the requirements of diverse applications.

- Q: What are the main applications of special steel in the defense vehicles?

- Special steel is widely used in defense vehicles for various applications. It is primarily used in the manufacturing of armored vehicles and tanks to provide enhanced protection against ballistic threats. Special steel is also used for constructing structural components, such as chassis and frames, due to its high strength and durability. Additionally, it is utilized in the production of critical parts like gears, axles, and suspension systems, as it offers excellent wear resistance and toughness. Overall, special steel plays a crucial role in ensuring the reliability, performance, and safety of defense vehicles.

- Q: What are the main factors affecting the creep rupture strength of special steel?

- The creep rupture strength of special steel is influenced by various key parameters. These factors can be categorized into several categories. Firstly, temperature plays a significant role in determining the creep rupture strength of special steel. The operating temperature affects atomic diffusion and dislocation movement, which in turn leads to accelerated deformation and eventual failure. Higher temperatures can greatly reduce the creep rupture strength of special steel. Secondly, the time duration of the applied load also affects creep rupture strength. Creep is a time-dependent phenomenon, meaning that the longer the steel is under stress, the more likely it is to experience rupture. The relationship between time and creep rupture strength is usually described by a power law equation, with longer durations resulting in lower rupture strength. The stress level is another critical factor that influences creep rupture strength. Higher levels of stress lead to faster deformation and shorter time to rupture. Therefore, it is important to ensure that the stress applied to special steel remains within an acceptable range to maintain its desired creep rupture strength. The microstructure of special steel is crucial in determining its creep rupture strength. Factors like grain size, grain boundary characteristics, and the presence of alloying elements all impact the steel's resistance to creep deformation and rupture. Fine-grained microstructures with a high density of grain boundaries tend to exhibit better creep resistance and higher rupture strength. The chemical composition of special steel also significantly affects its creep rupture strength. The addition of certain alloying elements, such as chromium, molybdenum, and vanadium, enhances the steel's high-temperature strength and resistance to creep deformation. These elements form stable carbides that hinder dislocation movement and improve the material's creep rupture strength. Furthermore, the heat treatment process used to modify the microstructure of special steel can also impact its creep rupture strength. Proper heat treatment optimizes grain size, the distribution of alloying elements, and overall microstructure, resulting in improved creep resistance and higher rupture strength. In conclusion, the creep rupture strength of special steel is influenced by temperature, time, stress level, microstructure, composition, and heat treatment. Understanding and controlling these parameters are vital in ensuring the desired performance and reliability of special steel in high-temperature and long-term applications.

- Q: How does hot rolling affect the microstructure of special steel?

- Hot rolling affects the microstructure of special steel by causing recrystallization and grain growth. The high temperature during the rolling process allows the steel to undergo plastic deformation, leading to the formation of new grains with a finer size. This results in improved mechanical properties such as increased hardness and strength. Additionally, hot rolling can also help in eliminating any residual stresses and improving the overall homogeneity of the steel's microstructure.

- Q: How does special steel contribute to the manufacturing of gears?

- Special steel plays a crucial role in the manufacturing of gears as it offers exceptional strength, durability, and wear resistance properties. The use of special steel allows gears to withstand heavy loads, high temperatures, and intense friction, ensuring their longevity and reliable performance. Moreover, the precise metallurgical properties of special steel enable gears to maintain their shape and dimensions accurately, resulting in smooth and efficient power transmission in various industries, including automotive, aerospace, and machinery.

Send your message to us

Hot Rolled Grade Sup6_Sup7_Sup9_SUP9A_Sup10 Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords