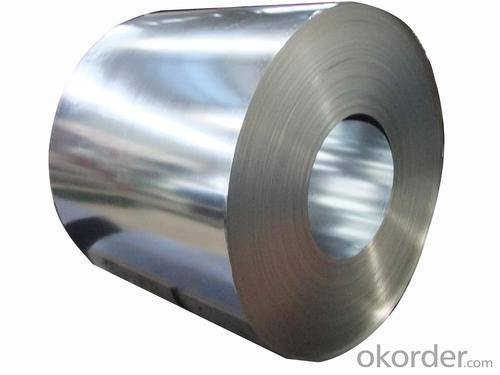

Hot rolled steel coil SS400/A36/Q235 pickled and oiled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Steel Grade: | Q235 | Thickness: | Thickness: 1.8mm-20mm |

| Place of Origin: | China (Mainland) | Technique: | Hot Rolled | Surface Treatment: | Other |

| Application: | Welded pipe, Hardeware and Bicycle manufacturing and so on | Model Number: | Steel Coil | Brand Name: | RGTS |

| Width: | 900mm-2000mm, 900-2000mm | Length: | As your requested | Surface: | black |

| Material Grade: | SS400\Q235\Q345B | Certificate:: | ISO | Package: | in bundles, strapped by strips. Or as customer's requirement |

Packaging & Delivery

| Packaging Details: | 1) Export standard packing in mill 2) Vertical or horizontal, properly packed for ocean freight exportation in one 20' or 40' containers 3) Ocean shipping in bulk-cargo ship |

| Delivery Detail: | within 15-30 days upon receipt original L/C at sight. |

Hot Rolled Pickled and Oiled Steel Coils

1. Production: Hot Rolled Pickled and Oiled Steel Coils

2. Port: Any port,China

3. Category: Minerals & metallurgy

4. Thickness: 1.8mm-20mm

5. Width: 900-2000mm

6. Coil Weight: about 23 tons

7. Material Grade : SS400\Q235\Q345B

8. Technique: Hot Rolled

9. Standard: GB ,JIS

10. Test: With Hydraulic Testing, Eddy Current , Infrared Test

11. Surface:

1) Bared

2) Black Painted (varnish coating)

3) Galvanized

4) Oiled

12. Package: in bundles, strapped by strips. Or as customer’s requirement

13. Sample:

Common products, we can provide freely, for special production,we can depends on negotiation.

14. MOQ: 10 tons

15. Payment: 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation

16.Delivery time: according to quantity, asap save customer’s time

17. Certificate: ISO

- Q: What are the applications of steel coils?

- Steel coils have a wide range of applications across various industries, such as construction, automotive, appliances, and manufacturing. They are primarily used in the production of sheet metal, pipes, and tubes, as well as for manufacturing parts and components. Steel coils are also used in the fabrication of various structures, including buildings, bridges, and infrastructure projects. Additionally, they find use in the production of household appliances, vehicles, machinery, and other consumer goods.

- Q: What are the challenges in coil slitting for thin gauge materials?

- Successfully operating coil slitting for thin gauge materials involves addressing a specific set of challenges. One major challenge is ensuring the proper handling and stability of the thin gauge material. The material's susceptibility to deformation, wrinkling, or tearing increases as it becomes thinner. To tackle this, careful attention must be given to the handling equipment and techniques used during the slitting process. This is necessary to maintain the appropriate tension and support throughout the operation. Another challenge is maintaining consistent and precise slitting widths. Thin gauge materials are often used in applications where accuracy is crucial, such as electronic components or automotive parts. Any variation in the slitting width can cause functional defects or assembly problems. Achieving precise slitting widths in thin gauge materials requires the use of high-quality slitting knives, well-maintained slitting machinery, and accurate tension control systems. In addition, thin gauge materials are more prone to surface defects, such as scratches or burrs, during the slitting process. These defects can impact the material's appearance, performance, or even its safety. To minimize the occurrence of surface defects, it is important to carefully select slitting knives and regularly maintain the slitting machinery. Furthermore, thin gauge materials often possess a higher yield strength, making them more resistant to deformation. This poses a challenge when it comes to achieving clean and straight edges during the slitting process. Special considerations must be taken to ensure that the slitting knives are sharp and properly aligned, allowing for clean cuts without introducing any edge defects. Lastly, thin gauge materials are generally more sensitive to external factors such as temperature, humidity, or static electricity. These factors can affect the material's dimensional stability, resulting in variations in slitting width or other quality issues. Therefore, it is crucial to establish appropriate environmental conditions and implement effective anti-static measures to minimize the impact of these factors. To summarize, the challenges associated with coil slitting for thin gauge materials revolve around handling and stability, maintaining precise slitting widths, minimizing surface defects, achieving clean and straight edges, and mitigating the influence of external factors. Overcoming these challenges requires a combination of suitable equipment, techniques, and operational controls to ensure high-quality slitting outcomes.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Wood, and it depends on the elements making up the 'conductor' .. and how 'mobile' electrons are in the material .. To a first approximation (non-exotic materials), if the elements form molecules where electrons are 'weakly bound', then that material will conduct electricity. The 'weaker' the binding (and the more electrons), the better the conductor .. (it is, of course, much more complicated than that .. see link)

- Q: What are the challenges in coil slitting?

- Coil slitting is a process used to cut large coils of metal into narrower strips of desired widths. While it offers several advantages in terms of efficiency and flexibility, there are also several challenges associated with coil slitting. One of the main challenges in coil slitting is ensuring consistent strip width accuracy. Since coil slitting involves cutting the metal coil into smaller strips, it is crucial to maintain consistent width measurements throughout the process. Any deviation in the strip width can lead to issues downstream in the production line, affecting the quality and functionality of the final product. This challenge requires the use of precise slitting equipment and careful monitoring of the process parameters. Another challenge in coil slitting is managing edge quality. The edge quality of the slit strips is critical, especially in applications where the edges need to be free from burrs or other imperfections. Achieving clean and smooth edges requires proper blade selection, positioning, and maintenance. Any defects or irregularities on the strip edges can impact subsequent processes like bending, welding, or coating. Additionally, coil slitting poses challenges related to the material itself. Certain types of metals, such as high-strength steels or alloys, can be more difficult to slit due to their hardness or brittleness. Slitting these materials may result in blade wear and premature failure, leading to increased downtime and maintenance costs. Furthermore, the presence of contaminants or surface defects on the coil can also affect the slitting process, requiring additional cleaning or preparation steps. Another significant challenge in coil slitting is handling and processing large coils. Coils can be heavy and unwieldy, making it crucial to have proper equipment and procedures in place to handle them safely. Additionally, the slitting process can generate significant amounts of scrap material, which needs to be efficiently managed and disposed of. Proper storage, transportation, and recycling of the scrap are essential to minimize waste and maintain a clean and organized working environment. In conclusion, coil slitting offers numerous benefits in terms of customization and productivity. However, it also presents challenges in maintaining strip width accuracy, managing edge quality, dealing with difficult materials, and handling large coils and scrap. Overcoming these challenges requires expertise, precision equipment, and careful process control to ensure the desired quality and efficiency in coil slitting operations.

- Q: Correct me if I am wrong, but steel is an alloy between iron and carbon. Does the carbon in the steel stops the iron from rusting or corroding? Also what is the difference between mild steel and stainless steel?

- Mild steel is an alloy. It is the most common form of steel. Mild steel (a so-called carbon steel) is a general term for a range of low carbon (a maximum of about 0.3%) steels that have good strength and can be bent, worked or can be welded into an endless variety of shapes for uses from vehicles (like cars and ships) to building materials. The carbon does not stop the material rusting or corroding. In addition to iron, carbon, and chromium, modern stainless steel may also contain other elements, such as nickel, niobium, molybdenum, and titanium. Nickel, molybdenum, niobium, and chromium enhance the corrosion resistance of stainless steel. It is the addition of a minimum of 12% chromium to the steel that makes it resist rust, or stain 'less' than other types of steel. The chromium in the steel combines with oxygen in the atmosphere to form a thin, invisible layer of chrome-containing oxide, called the passive film. The sizes of chromium atoms and their oxides are similar, so they pack neatly together on the surface of the metal, forming a stable layer only a few atoms thick. If the metal is cut or scratched and the passive film is disrupted, more oxide will quickly form and recover the exposed surface, protecting it from oxidative corrosion.

- Q: Why are properties of steel not identical?

- Steel is manufactured to different specs. To match the needs of its intended end use .Tensel strength,Hardness, Corosion resistance etc. The chemical make up will change to suit.

- Q: How are steel coils used in the manufacturing of signage?

- Steel coils are used in the manufacturing of signage as they serve as the base material for creating durable and sturdy sign structures. These coils are shaped, cut, and processed into various sign components, such as frames, brackets, and supports, which provide stability and strength to the signage. Additionally, steel coils can be coated or painted to enhance the appearance and protect the signage from corrosion, making them ideal for outdoor applications.

- Q: What are the different methods of forming steel coils?

- There are several methods used for forming steel coils, depending on the specific requirements and applications. These methods include hot rolling, cold rolling, and continuous casting. Hot rolling is the most common method used for forming steel coils. It involves heating the steel billet or ingot to high temperatures and then passing it between a series of rollers to reduce its thickness and shape it into a coil. This process is typically performed above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. Cold rolling, on the other hand, is a process that is performed at or near room temperature. It involves passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often employed to produce steel coils with precise dimensions and excellent surface finish. It can also increase the strength and hardness of the steel. Continuous casting is another method used for forming steel coils. It involves pouring molten steel into a continuous casting machine, where it is solidified into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, such as improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These include pickling, annealing, and coating. Pickling removes any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which helps to improve its ductility and reduce internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. In summary, the different methods of forming steel coils include hot rolling, cold rolling, and continuous casting. Each method offers unique advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes such as pickling, annealing, and coating are often employed to further enhance the quality and performance of the steel coils.

- Q: What are the standard dimensions and weights of steel coils?

- The standard dimensions and weights of steel coils can vary depending on the specific type and grade of steel being used, as well as the manufacturing process and intended application. However, there are some common industry standards that can provide a general idea of the dimensions and weights of steel coils. In terms of dimensions, steel coils typically have a standard width ranging from 600mm to 2000mm or more, with the most common widths being 1000mm, 1250mm, and 1500mm. The inner diameter of the coil, also known as the core or mandrel, is usually around 508mm (20 inches) or 610mm (24 inches). The outer diameter of the coil, also known as the outside diameter or OD, can vary widely depending on the thickness and width of the coil, but it is typically in the range of 1200mm to 2000mm. As for weights, steel coils are measured in terms of their gross weight, which includes the weight of the coil itself along with the steel material it contains. The weight of a steel coil can range from a few hundred kilograms to several tonnes, depending on the thickness and width of the coil. For example, a coil with a thickness of 0.5mm and a width of 1000mm may weigh around 5-6 tonnes, while a coil with a thickness of 3mm and a width of 1500mm can weigh around 20-25 tonnes. It's important to note that these dimensions and weights are just general guidelines and may vary depending on the specific requirements and standards of different industries and manufacturers. Therefore, it is always recommended to consult the relevant specifications or contact the manufacturer for accurate and up-to-date information regarding the dimensions and weights of steel coils.

- Q: What are the different types of steel coil slitting machines?

- There are several types of steel coil slitting machines, including rotary slitters, loop slitters, and stationary slitters. Rotary slitters use rotating circular blades to cut the coils into desired widths, loop slitters use a looping process to cut the coils, and stationary slitters use stationary blades to slit the coils. Each type of machine has its own advantages and is suitable for different applications.

Send your message to us

Hot rolled steel coil SS400/A36/Q235 pickled and oiled steel coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords