Hot Rolled Stainless Steel Coil (304/NO. 1)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil description:

Model NO.:304

Type:Stainless Steel Strips

Shape:Coil

Grade:300 Series

Certification:SGS

Standard:AISI

Technique:Hot Rolled

Surface Treatment:Hot Rolled

Export Markets:Global

Packing:Standard Export Packing

Standard:ASTM, GB, SUS

Origin:China

Production Capacity:10000 Mt/Month

Product specification:

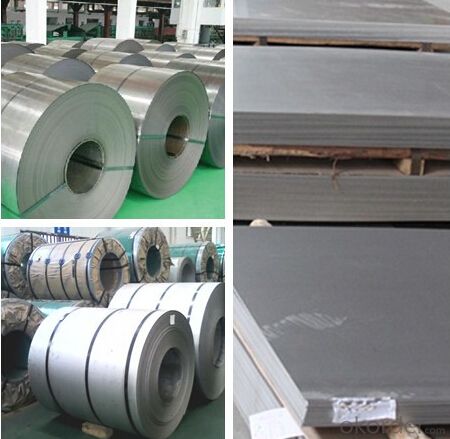

Commodity: Hot rolled stainless steel coil

Grade: 304

Finish: No. 1

Thickness: 3.0mm to 20.0mm

Width: 1219mm, 1500mm

Mill: TISCO, LISCO, BAOXIN, JISCO, SOUTHWEST

Quantity: 3000-5000MT every month

Thickness tolerance: +/-6%

Packing: Export standard packing

Coil weight: 10-20MT

Delivery time: Immediate shipment

Applications: Stainless Steel Cold Rolled Coils are widely applied to construction field, ships building industry, petroleum and chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: How are steel coils used in the production of steel nails?

- Steel coils are used in the production of steel nails as they serve as the primary raw material. These coils are unwound and fed into a nail-making machine, where they are cut into the desired length and shaped into nails.

- Q: How are steel coils used in the manufacturing of agricultural implements?

- Steel coils are used in the manufacturing of agricultural implements as they are shaped and formed into various components such as blades, tines, and frames. These components are then assembled to create durable and reliable equipment that is used for tilling, planting, harvesting, and other farming activities. The strength and versatility of steel coils make them ideal for creating robust and long-lasting agricultural implements.

- Q: How are steel coils inspected for coil weight accuracy?

- Steel coils are inspected for coil weight accuracy through the use of weighing scales or load cells. These devices are placed beneath the coil during the inspection process to accurately measure its weight.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are highly regarded for their exceptional strength and durability, making them superior to other types of metal coils. Steel is known for its high tensile strength, allowing it to withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Various protective layers, such as zinc or paint, can be applied to steel to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a diverse range of mechanical properties that can be customized through different manufacturing processes. This allows for the production of steel coils with specific characteristics, including high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. When compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils are distinguished by their exceptional strength, durability, corrosion resistance, versatility, and affordability. These qualities make steel coils the preferred choice for a wide range of industries, including construction, manufacturing, transportation, and energy.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork to form the main structure of the ducts. The steel coils are processed and shaped into specific sizes and dimensions, allowing them to be easily fabricated into duct sections. These coils provide strength and durability to the ductwork, ensuring it can withstand the high pressures and temperatures involved in HVAC systems.

- Q: What are the different methods of welding steel coils?

- There are several methods of welding steel coils, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. MIG welding uses a consumable electrode wire and an inert gas as a shielding medium to create an arc and join the coils. TIG welding, on the other hand, uses a non-consumable tungsten electrode and a separate filler material to create the weld. Resistance welding involves applying pressure and passing an electric current through the coils to create a weld. Each method has its advantages and is chosen based on factors such as the type and thickness of the steel, desired quality, and production requirements.

- Q: What are the common coil coating methods?

- The common coil coating methods include roll coating, spray coating, and coil coating with pre-painted metal substrates.

- Q: How are steel coils inspected for formability?

- Steel coils are typically inspected for formability through a combination of visual inspection, mechanical testing, and laboratory analysis. Visual inspection involves examining the surface of the coil for any visible defects such as scratches, dents, or deformities that could affect its formability. This is usually done by trained personnel who carefully inspect the entire surface of the coil. Mechanical testing is also commonly employed to assess the formability of steel coils. This can include conducting physical tests such as tensile testing, where a sample is subjected to controlled forces to measure its strength and elongation properties. This helps determine if the steel has the necessary ductility and strength to be formed into the desired shape without cracking or breaking. Additionally, laboratory analysis is often conducted to assess the chemical composition and microstructure of the steel. This involves taking small samples from the steel coil and analyzing them using techniques such as spectroscopy and microscopy. These analyses can provide valuable insights into the steel's composition, grain structure, and other characteristics that can impact its formability. Overall, a combination of visual inspection, mechanical testing, and laboratory analysis is used to ensure that steel coils meet the required formability standards. This comprehensive approach helps identify any potential issues or defects that could affect the performance and reliability of the steel when it is formed into its intended shape.

- Q: What are the different methods of blanking steel coils?

- There are several methods for blanking steel coils, including shearing, laser cutting, and waterjet cutting. Shearing involves using sharp blades to cut the coil into desired shapes. Laser cutting utilizes a high-powered laser beam to accurately cut through the steel. Waterjet cutting involves the use of a high-pressure stream of water mixed with abrasive materials to cut the coil. These methods offer different levels of precision, speed, and cost-effectiveness depending on the specific requirements of the blanking process.

- Q: Are steel coils used in agricultural equipment manufacturing?

- Yes, steel coils are commonly used in agricultural equipment manufacturing. Steel coils are often used to produce various components and parts for agricultural machinery, such as plows, harvesters, tractors, and tillers. The use of steel coils in agricultural equipment manufacturing ensures durability, strength, and resistance to various environmental conditions, making them essential in this industry.

Send your message to us

Hot Rolled Stainless Steel Coil (304/NO. 1)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords