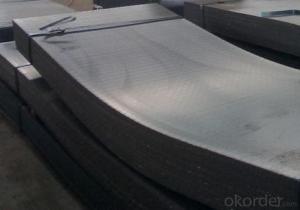

Hot Rolled Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, DIN, GB, JIS | Grade: | A572,A573,A633,A678,A709,A710,G3101,G3136,etc | Thickness: | 1mm-200mm |

| Brand Name: | SHOU GANG GROUP, AN STEEL | Model Number: | Q235 | ||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | widely | Special Use: | High-strength Steel Plate | Width: | 1000mm-3000mm |

| Length: | 1000mm-12000mm | Price Term: | FOB CIF CFR |

Packaging & Delivery

| Packaging Details: | standard seaworthy export packing or as the request of customers |

| Delivery Detail: | 10 days after deposit or according to customers' quantity |

Specifications

hot rolled carbon steel sheet

1.Thickness:1mm-200mm

2.Length:1000mm-12000mm

3.Width:1000mm-2000mm

hot rolled carbon steel sheet

| Product | HR steel plate prices carbon steel plate prices per kg |

| MOQ | 25 ton |

| Thickness | 1mm-200mm |

| Width | 1000mm-3000mm |

| Length | 1000mm-12000mm |

| Application | widely |

| Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

| Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

| Tpye | Steel plate |

| Surfacing | Coated |

| Productive Technology | Hot Rolled & Cold Rolled |

| Port | |

| Payment Terms | L/C,T/T,Western Union,MoneyGram |

| Product Ability | 5000 tons per month |

| Delivery | 10 days after deposit or according to customers' quantity |

| Packing | standard seaworthy export packing or as the request of customers |

- Q: What is the average lifespan of steel sheets used for roofing?

- The lifespan of steel sheets used for roofing can vary based on several factors. Nevertheless, high-quality steel roofing sheets are designed to be extremely durable and long-lasting. On average, these steel sheets can endure for 40 to 70 years or potentially even longer if properly maintained and cared for. The longevity of steel roofing sheets can be influenced by factors such as the steel type and thickness, the coating or finish quality, the climate and weather conditions in the area, and the level of maintenance. Conducting regular inspections, cleaning, and repairs as necessary can help extend the lifespan of the steel sheets and ensure their good condition for many years. It is always advisable to seek guidance from roofing professionals or manufacturers for specific guidelines and recommendations regarding the lifespan of steel sheets used for roofing in a particular context.

- Q: Can steel sheets be used for making shipping containers?

- Yes, steel sheets can be used for making shipping containers. Steel is a commonly used material in the construction of shipping containers due to its strength, durability, and ability to withstand harsh weather conditions.

- Q: What are the different types of steel sheet finishes for industrial applications?

- Various types of steel sheet finishes are commonly utilized in industrial applications for different purposes. These finishes are applied to steel sheets to improve their appearance, safeguard against corrosion, enhance paint adhesion, and offer other functional advantages. Among the most frequently employed steel sheet finishes are: 1. Hot Rolled: Achieved by subjecting the steel to high temperatures in a furnace, followed by rapid cooling. This process creates a rough, scaled surface suitable for applications where appearance is not the primary concern. 2. Cold Rolled: Processed at room temperature, resulting in a smooth and clean surface. Cold-rolled steel sheets are often used when a high-quality surface finish is required. 3. Galvanized: Involves applying a layer of zinc to the steel sheet to protect against corrosion. Widely used in construction, automotive, and manufacturing industries where durability and resistance to rust are crucial. 4. Electro-galvanized: Similar to galvanizing, this process coats the steel with zinc. However, it utilizes an electric current to deposit a thinner and more controlled zinc coating onto the steel surface. 5. Stainless Steel: Known for its high corrosion resistance, stainless steel sheets are ideal for use in harsh environments. They can be finished with various surface textures, including brushed, mirror, and patterned finishes. 6. Pickled and Oiled: This finish removes any oxide scale from the steel surface using an acid solution and applies an oil coating to prevent rust formation. Commonly used in automotive and construction industries. 7. Painted: Steel sheets can be finished with a layer of paint, which enhances their appearance and provides additional protection against corrosion. The choice of paint depends on the application and desired finish. It is important to note that the examples mentioned above are just a few of the steel sheet finishes used in industrial applications. Different finishes are selected based on specific requirements, such as aesthetics, corrosion resistance, durability, and cost-effectiveness.

- Q: Can steel sheets be used in renewable energy applications?

- Yes, steel sheets can be used in renewable energy applications. Steel is widely used in the construction of wind turbines, solar panels, and other renewable energy infrastructure. It is durable, strong, and can withstand harsh environmental conditions, making it a suitable material for these applications. Additionally, steel is recyclable, which aligns with the sustainability goals of renewable energy projects.

- Q: Can steel sheets be used for stairs and handrails?

- Yes, steel sheets can be used for stairs and handrails. Steel sheets can be fabricated into various shapes and sizes, making them suitable for constructing stairs and handrails. They are durable, strong, and can provide a modern and sleek look to the overall design. Additionally, steel sheets can be easily customized and installed, making them a popular choice for both residential and commercial applications.

- Q: What are steel sheets used for?

- Steel sheets are commonly used in construction and manufacturing industries for various applications such as roofing, cladding, automotive bodies, appliances, and structural components.

- Q: Can steel sheets be used for food processing or storage?

- Yes, steel sheets can be used for food processing or storage. Steel is a durable and hygienic material that is commonly used in the food industry due to its resistance to corrosion, easy cleaning, and ability to maintain proper food safety standards.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets varies depending on the specific grade and thickness of the steel. However, it typically ranges from 250 to 400 megapascals (MPa).

- Q: How much is a steel sheet per square meter?

- The influence of steel prices, in addition to material related, but also with the thickness of the steel plate, thin steel plate prices will be more expensive

- Q: Can steel sheets be used for solar panel mounting?

- Yes, steel sheets can be used for solar panel mounting. Steel is a durable and strong material that can provide the necessary support for solar panels. It can be used as a reliable base for secure and stable installation, ensuring the longevity and stability of the solar panel system.

Send your message to us

Hot Rolled Carbon Steel Sheet CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords