Colorful Coated Aluminum Coil - Hot Items 1, 3, 5 Ultra Thick Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Items 1, 3, 5 Ultra Thick Aluminium Sheet

l Product Information

Product | Alloy designation | Supply status | Thickness(mm) | Width(mm) | length(mm) |

Quench aluminium plate | 2 series, 6 series, 7 series | T3,T4,T42, T6,T62,T73, T74 | 0.5~150 | Under 2000 | Under 11000 |

Pre-stretching version plate | 1~8 series | Various forms | 2.0~180 | Under 1600 | Under 4000 |

Checkered plate | 1 series, 3 series, 5 series | H224,H114, O,H234 | 1.0~8.0 | Under 1900 | Under 12000 |

Hot rolled plate | 1~8 series | F,H111,H112 | 4.0~300 | Under 2200 | Under 11000 |

Hot rolled stock | 1~8 series | F,H111,H112 | 4.0~15 | Under 2300 | C |

Plate | 1~8 series | Various forms | 0.15~300 | Under 2200 | Under 12000 |

Coiled material | 1~8 series | Various forms | 0.15~15 | Under 2200 | C |

Air-conditioning foil | 8011,3012 | H22,H24 | 0.09~0.15 | Under 1300 | C |

Curtain wall plate | 1060,1050 , 1100,3003 3004,5052 | H14,H24,O | 1.0~5.0 | Under 2200 | Under 12000 |

Aluminium foil | 1060,1100, 8011,1235, 3003 | Various forms | 0.008~0.2 | Under 1500 | C |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

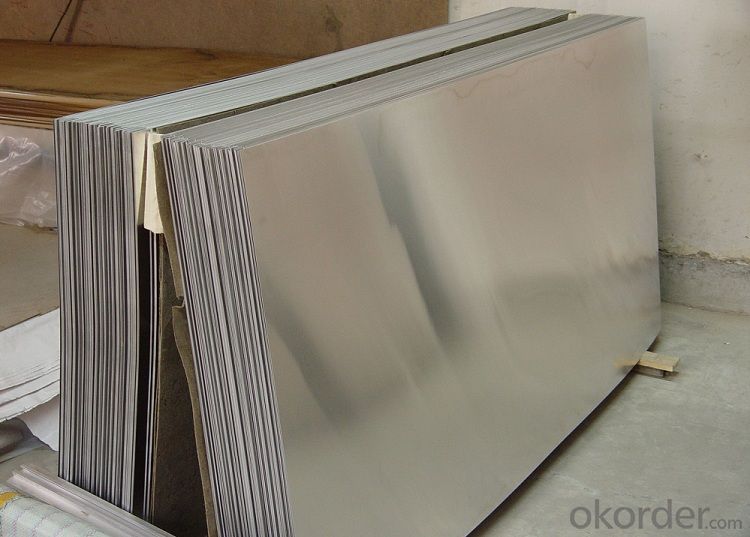

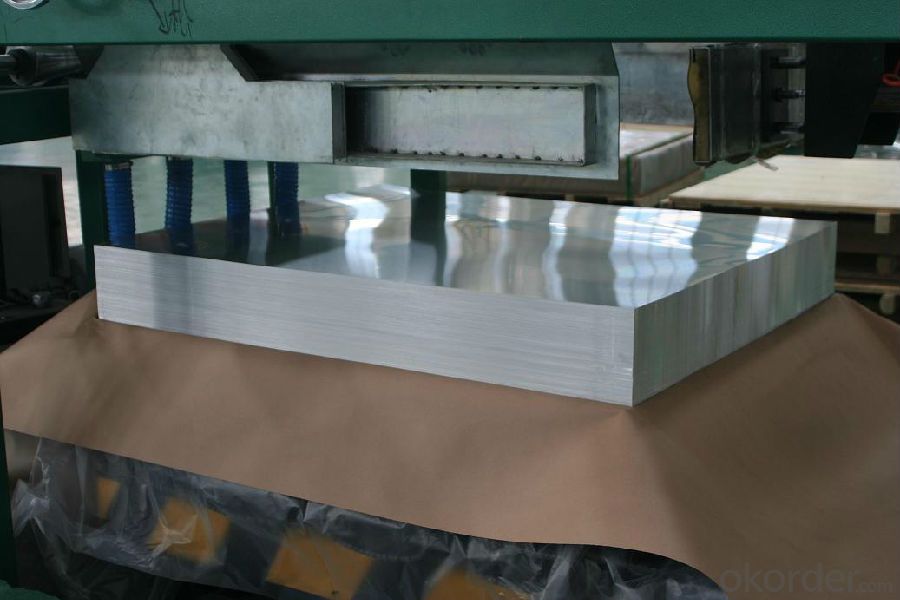

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a high-quality aluminum coil, consider the following factors: purity level, which should be 99.5% or higher for most applications; surface finish, ensuring it's smooth and free from defects; thickness consistency, which should be uniform across the entire coil; mechanical properties, such as tensile strength and elongation, that meet industry standards; and adherence to specific alloy grades for particular applications. Additionally, check for certifications from recognized standards organizations and consider the supplier's reputation for quality and consistency.</p>

- Q: Can aluminum coils be used in the construction industry?

- Yes, aluminum coils can be used in the construction industry. Aluminum is a versatile and lightweight material that offers several advantages for construction applications. Aluminum coils are commonly used in the construction industry for various purposes, such as roofing, siding, gutters, and fascia. One of the main benefits of using aluminum coils in construction is its corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, which prevents rust and corrosion. This makes it highly suitable for exterior applications, where exposure to moisture and weather elements is common. Additionally, aluminum coils are easy to shape and work with, making them ideal for creating custom components and structures. They can be easily cut, bent, and formed into different shapes, allowing for flexibility and creativity in construction projects. Another advantage of aluminum coils is their lightweight nature. Aluminum is significantly lighter than other metals like steel, making it easier to handle and transport. This can reduce construction costs and make installation processes more efficient. Furthermore, aluminum is a sustainable and environmentally-friendly material. It is 100% recyclable and can be reprocessed repeatedly without losing its properties. This makes aluminum coils an eco-friendly choice for construction projects. In conclusion, aluminum coils are widely used in the construction industry due to their corrosion resistance, flexibility, lightweight nature, and sustainability. They offer numerous advantages for various applications and contribute to the overall efficiency and durability of construction projects.

- Q: The temperature of the water drops from 93.0°C to 78.0°C. What quantity of heat energy did the piece of aluminum absorb?

- The specific heat of Aluminum is 0.215 cal/g-°C. The calories absorbed (q) would be q = m * c * (T2 -T1) = 22.0 g * 0.215 cal/g-°C * (78.0 °C - 0.3 °C) If you have a different value for the Specific heat of Aluminum, use it in the formula for your calculations. If you knew the mass of the water, you could check your calculations because the heat gained by the Al would be equal to the heat lost by the water, using q = m * c * (T2 -T1), where m is the mass of the water, c = 1.00 calorie/gram °C, T2 = 78.0 °C and T1 = 93.0 °C. The sign of q will be negative.

- Q: Is it safe and effective to heat an aluminum coil using a microwave oven?

- <p>No, you should not use a microwave to heat an aluminum coil. Microwaves can cause aluminum to heat unevenly and potentially spark, which is dangerous. Aluminum is a good conductor of electricity and can reflect microwaves, leading to arcing and fire hazards. Always use microwave-safe materials when heating food or other substances in a microwave.</p>

- Q: Can aluminum coils be used in the production of electronic components?

- Indeed, electronic components can utilize aluminum coils in their production. Aluminum, a highly versatile and extensively employed metal across diverse industries, including electronics, harbors numerous benefits. Notably, it possesses a lightweight nature, exceptional thermal conductivity, resistance to corrosion, and superb electrical conductivity. These remarkable properties render aluminum coils fitting for deployment in electronic components, encompassing capacitors, transformers, inductors, and heat sinks. By incorporating aluminum coils in electronic components, the dissipation of heat becomes more efficient, performance is enhanced, and the overall weight of electronic devices is reduced.

- Q: How are aluminum coils used in the production of cookware?

- Aluminum coils are used in the production of cookware as they are rolled into thin sheets and then formed into various shapes like pots, pans, and trays. These coils are lightweight, conduct heat efficiently, and have excellent heat distribution properties, making them ideal for cookware manufacturing. Additionally, aluminum's non-reactive nature ensures that it does not alter the taste or quality of the food being cooked.

- Q: How does the gauge of aluminum coils affect their performance?

- The thickness of the aluminum sheet used to make the coil determines the gauge of aluminum coils. The gauge is typically measured by its thickness, with a smaller gauge indicating a thicker sheet. The performance of aluminum coils is significantly influenced by their gauge. To begin with, the strength and durability of the aluminum coil are affected by the gauge. Thicker gauges offer greater strength and resistance to bending or warping, making them suitable for applications that require sturdy and long-lasting coils. Conversely, thinner gauges are more flexible but may be prone to damage or deformation, making them suitable for less demanding applications. Furthermore, the gauge affects the thermal conductivity of the aluminum coil. Thicker gauges have lower thermal conductivity, resulting in slower heating or cooling. This characteristic can be advantageous in applications where precise temperature control is crucial, as it helps maintain a stable environment. On the other hand, thinner gauges have higher thermal conductivity, enabling faster heat transfer. This can be beneficial in applications that require rapid heating or cooling. Moreover, the gauge affects the weight and cost of the aluminum coil. Thicker gauges are heavier and generally more expensive due to the increased amount of material required. This factor is important to consider in applications where weight or cost plays a significant role. Thinner gauges, being lighter and less expensive, are more suitable for applications that prioritize weight reduction or cost efficiency. Lastly, the gauge influences the ease of fabrication and formability of the aluminum coil. Thinner gauges are more easily bent, shaped, or formed into desired configurations, making them suitable for applications that involve intricate or complex designs. Although thicker gauges are less malleable, they can still be formed with specialized equipment or processes. In conclusion, the gauge of aluminum coils directly affects their performance. It influences their strength, durability, thermal conductivity, weight, cost, and formability. Therefore, selecting the appropriate gauge for a specific application is crucial to ensure optimal performance and efficiency.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

- Q: I want to make arrows for my bow that making, i have an idea of making a wooden mold and then finding the melting point of aluminum foil and melt it, prob is that i dont have anything to melt it with my moms oven goes up to only 500F and i need one up to 1240F

- Buy the arrows. It is cheaper and probably safer.

- Q: This question asks about potential health hazards linked to the use of aluminum coils in culinary settings.

- <p>There are some concerns about using aluminum cookware due to the potential for aluminum to leach into food, especially at high temperatures or in acidic environments. While the human body needs small amounts of aluminum, excessive intake can be harmful. It has been linked to neurological disorders, although the evidence is not conclusive. Most health organizations, including the FDA, consider aluminum cookware safe for general use. However, for those who are concerned, alternatives like stainless steel, cast iron, or non-stick coatings are available. It's always best to follow manufacturer's guidelines and avoid using aluminum cookware for acidic or highly acidic foods to minimize any potential risk.</p>

Send your message to us

Colorful Coated Aluminum Coil - Hot Items 1, 3, 5 Ultra Thick Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords