Hot Dipped Galvanized steel Pipe Gold supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gold supplier Hot Dipped Galvanized steel Pipe Details

| Thickness: | 0.45 - 15 mm | Section Shape: | Round | Outer Diameter: | 10.3 - 219 mm |

| Place of Origin: | Tianjin China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe,Industry |

| Technique: | ERW | Certification: | ISO9001,ISO | Surface Treatment: | Galvanized |

| Special Pipe: | Thick Wall Pipe | Alloy Or Not: | Non-alloy | Brand Name: | TJXAHY |

| packing: | as your requirements | galvanized steel pipe: | galvanized steel pipe | galvanized pipe BS 1387-1985: | galvanized pipe BS 1387-1985 |

| hot dip galvanized pipe: | hot dip galvanized pipe | Samples: | can be provided | product name: | Gold supplier !!!!! Hot Dipped Galvanized Pipe |

| Name: | Hot Dipped Galvanized steel Pipe | Grade: | 10#,20#,45#,16Mn,A106(B,C),A335, P11,A53(A,B),Q195,Q215,Q235,Q345,10#-45#,A53-A369,Q195-Q345 | Standard: | ASTM A106-2006,BS |

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 7--20days after receiving the deposit |

Gold supplier Hot Dipped Galvanized steel Pipe Specification

O.D | O.D tolerance | W.T | Thickness Tolerance |

10.3--219MM | ±0.03 | 0.6--10MM | ±0.02 |

Length | 2--12M,according to customers' requirements | ||

Zinc coating | 275--350g/m2 | ||

International Standard | ISO 9001;2008 | ||

Standard | ASTM A 53/BS 1387-1985 | ||

Material | Q195/Q215/Q235/Q345 | ||

Product Category : | Metallurgy,Mineral & Energy | ||

Technique: | Welded | ||

Usage | 1.For low pressure liquid delivery such as water,gas and oil 2.For construction,e.g building greenhouse | ||

Main market: | Middle east,Africa,North and South America,East and West Europe,South and southeast Asia,Australia | ||

Place of Origin | China | ||

HS code: | 7306309000 | ||

Remarks | 1)Payment term:T/T 2)Trade Terms:FOB/CFR/CIF 3)Minimum quantity of order:25 MT (25,000KGS) 4)Delivery period:10 to 30 Days. | ||

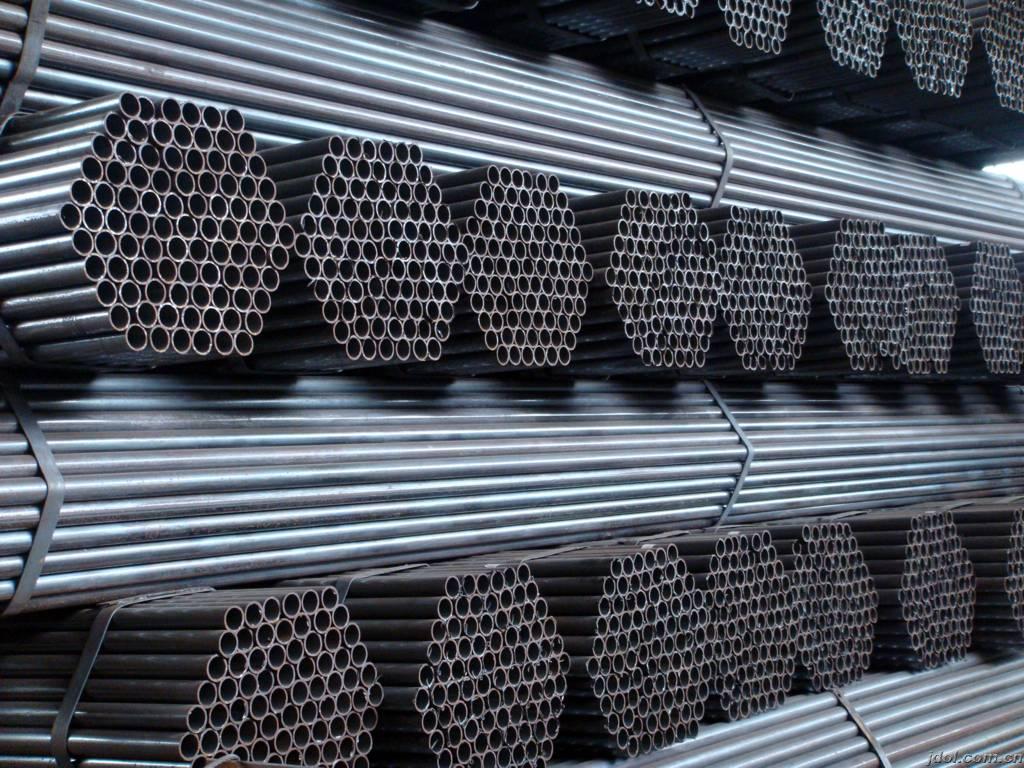

Gold supplier Hot Dipped Galvanized steel Pipe Pictures

- Q: What is the production process of seamless steel tube?

- The delivery status of hot-rolled seamless steel tubes is generally hot-rolled and delivered after heat treatment. Hot rolled seamless steel tube after quality inspection after staff strict hand picked in quality inspection should be carried out after the oil surface, followed by cold drawing experiments, hot rolling process should be carried out after the perforation experiment, if perforated expanding too large to carry out straightening correction. After straightening, the device is sent to the flaw detector by the transfer device to carry out the flaw detection experiment. Finally, the label is attached and the specifications are arranged and placed in the warehouse.

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports used for aboveground steel pipes, including pipe hangers, pipe clamps, pipe shoes, and pipe saddles. These supports are designed to provide stability and prevent excessive movement or sagging of the pipes. They help distribute the weight of the pipes evenly and ensure proper alignment and support throughout their length.

- Q: What is the difference between carbon steel and cast iron pipes?

- Carbon steel and cast iron pipes are both widely used in various industries for different applications. The main difference between these two types of pipes lies in their composition and properties. 1. Composition: Carbon steel pipes are primarily made of iron and carbon, with trace amounts of other elements such as manganese, phosphorus, and sulfur. On the other hand, cast iron pipes are made by melting iron and adding a small amount of carbon, usually between 2-4%. 2. Strength and Durability: Carbon steel pipes are generally stronger and more durable than cast iron pipes. Carbon steel has a higher tensile strength, which means it can withstand higher pressures and is less likely to be damaged or deformed. Cast iron, although strong, is more brittle and prone to cracking. 3. Corrosion Resistance: Carbon steel pipes require additional coatings or treatments to protect them from corrosion. Without proper protection, carbon steel pipes can be susceptible to rust and corrosion, especially when exposed to moisture or aggressive substances. On the other hand, cast iron pipes have inherent corrosion resistance due to the formation of a protective layer of iron oxide (rust) on their surface. 4. Weight and Installation: Cast iron pipes are typically heavier than carbon steel pipes, making them more challenging to handle and install. Carbon steel pipes are comparatively lighter, allowing for easier transportation and installation. 5. Noise and Vibration: Cast iron pipes have superior sound-deadening properties, making them quieter when fluids flow through them. On the contrary, carbon steel pipes tend to transmit more noise and vibrations. 6. Cost: Cast iron pipes are generally more expensive than carbon steel pipes due to the additional manufacturing processes and the higher cost of raw materials. In summary, the main differences between carbon steel and cast iron pipes lie in their composition, strength, corrosion resistance, weight, noise transmission, and cost. The choice between the two depends on the specific application, budget, and environmental factors.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes. They are commonly used to create the foundation structures, such as monopiles and jacket structures, which provide stability and support for the turbines in the seabed. Steel pipes are also utilized for the construction of the tower and nacelle structures, providing a strong and durable framework for the turbine components. Additionally, steel pipes are employed for the installation of subsea cables, allowing for the transmission of electricity generated by the turbines to the shore. Overall, steel pipes play a crucial role in the manufacturing of offshore wind turbines by providing the necessary strength, stability, and infrastructure required for their operation.

- Q: How do steel pipes handle extreme weather conditions?

- Steel pipes are highly durable and can withstand extreme weather conditions. They have excellent resistance to corrosion, which allows them to maintain their structural integrity even in harsh environments. Additionally, steel pipes have high tensile strength, making them resistant to bending, cracking, or collapsing under extreme weather events such as strong winds, heavy snow, or intense heat. Overall, steel pipes are a reliable choice for handling extreme weather conditions.

- Q: Are steel pipes suitable for desalination plants?

- Desalination plants can benefit greatly from the use of steel pipes. These pipes possess a variety of advantages that make them an ideal option for such facilities. Firstly, their resistance to corrosion is of utmost importance in desalination plants, where saltwater can be highly corrosive. The fact that steel pipes can withstand such corrosive conditions ensures the durability and longevity of the infrastructure, ultimately reducing maintenance and replacement expenses. Secondly, steel pipes exhibit remarkable strength, enabling them to withstand high-pressure situations commonly encountered in desalination plants. The ability of steel pipes to handle intense water flow without deformation or leakage guarantees the efficient and dependable operation of the desalination process. Moreover, steel pipes boast excellent heat resistance properties, rendering them suitable for desalination plants that engage in heat-intensive procedures like distillation or reverse osmosis. These pipes can endure high temperatures without suffering any structural damage, ensuring the secure and efficient transfer of heated water or steam. Furthermore, steel pipes are readily available and come in a wide range of sizes and specifications, allowing for flexibility in the design and construction of desalination plants. This availability and versatility make steel pipes a cost-effective choice for desalination projects. Overall, due to their resistance to corrosion, high strength, heat resistance, availability, and cost-effectiveness, steel pipes are highly suitable for desalination plants and are extensively used in the industry.

- Q: How are steel pipes used in the construction of tunnels?

- Steel pipes are used in the construction of tunnels for various purposes such as drainage, ventilation, and transportation of utilities. They provide structural support, ensuring stability and strength, while also allowing for the efficient flow of water, air, and other essential resources within the tunnel.

- Q: What is the difference between steel pipes and aluminum pipes?

- The main difference between steel pipes and aluminum pipes lies in their composition and properties. Steel pipes are made of an alloy of iron and carbon, which provides them with excellent strength and durability. They are often used in applications that require high-pressure or extreme temperatures. On the other hand, aluminum pipes are composed of aluminum, a lightweight metal that offers good corrosion resistance. Aluminum pipes are commonly used in industries where weight is a concern, such as aerospace and automotive. Overall, the choice between steel and aluminum pipes depends on the specific requirements of the application.

- Q: How are steel pipes used in the manufacturing of boilers?

- Due to their strength, durability, and heat-resistant properties, steel pipes are essential components in the manufacturing of boilers. Boilers are utilized in various industrial and commercial applications to generate steam or heat water. The construction of boiler tubes is where steel pipes are primarily employed, as they function as the main heat transfer medium. Considering the high temperatures and pressure that these tubes are subjected to, it is crucial to use a material that can withstand such extreme conditions. Steel, with its excellent mechanical properties and corrosion resistance, is the ideal choice for this purpose. To create the boiler tubes, the manufacturing process involves shaping and sizing the steel pipes accordingly. These tubes are then connected to form a network of channels through which hot gases or water can flow. Depending on the boiler design requirements, the steel pipes utilized in this process are often seamless or welded. For the safety and efficiency of the system, the steel pipes used in boilers must meet stringent quality standards. They are subjected to tests to ensure their ability to withstand high pressure, temperature, and corrosion. Furthermore, inspections and tests such as ultrasonic testing and radiographic examination are conducted to identify any defects or flaws that might compromise the performance of the boiler. In conclusion, steel pipes play a critical role in the manufacturing of boilers by serving as the primary material for boiler tubes. Their strength, durability, and heat-resistant properties make them suitable for enduring high temperatures and pressure. These pipes undergo rigorous testing to guarantee their quality and reliability in creating efficient and safe boiler systems.

- Q: How are steel pipes repaired in case of damage?

- Steel pipes are typically repaired by first identifying the damaged section of the pipe. Then, the damaged area is cut out and replaced with a new section of pipe. This new section is welded or clamped into place to ensure a secure connection. In some cases, epoxy or other sealants may be used to repair smaller cracks or leaks. Overall, the repair process aims to restore the structural integrity and functionality of the steel pipes.

Send your message to us

Hot Dipped Galvanized steel Pipe Gold supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords