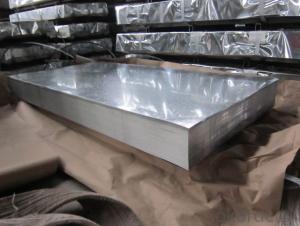

HOT-DIPPED GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How are steel coils inspected for formability using forming tests?

- Steel coils are inspected for formability using forming tests to assess their ability to be shaped into desired forms without any defects or failures. These tests are conducted to evaluate the material's mechanical properties and determine its suitability for specific applications. Forming tests involve subjecting the steel coil to various forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specified dimensions and then subjected to these operations using specialized equipment. The key objective is to simulate the actual forming process that the steel will undergo in real-world applications. During the forming tests, several parameters are closely monitored. These include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the coil's response to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By carefully analyzing the performance of the steel coil during the forming tests, various formability characteristics can be determined. These include the material's resistance to deformation, its ability to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for specific forming processes and applications. Moreover, advanced techniques such as digital image correlation and strain analysis may be employed to precisely measure and evaluate the strain distribution across the steel coil's surface. These techniques help identify regions of the coil that experience higher strain and potential failure points. In conclusion, steel coils are inspected for formability using forming tests that simulate the actual forming processes they will undergo. These tests assess various formability characteristics, including the material's resistance to deformation and its propensity for defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: What is the standard length of steel coils?

- The standard length of steel coils can vary depending on the specific industry and application. However, common standard lengths range from 1000 to 6000 millimeters or 3 to 20 feet.

- Q: Im getting a new guitar soon, and it has steel strings. ive heard that nilon strings are better? thanks:)

- Classical okorder /... P.S Classical guitars are not limited to playing classical music but that is generally what they are used for.

- Q: What is the typical weight of a steel coil?

- The typical weight of a steel coil varies widely depending on its size, thickness, and type of steel used. However, a common range for steel coils is between 3 to 25 metric tons.

- Q: i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- Basically all the others are right, except Skeptical who never answered your question. Just thru out an insult....what was that you said about growing up?...hmmmmm Also Skeptical...take a look at modern day guns (pistols and rifles), holsters, knives, even bullet, packaging and boxes for the above. You don't think looks play a role in design? Aesthetics and whether something is pleasing to the eye ALWAYS plays a role in marketing. To answer the question though, it allows the shell expansion to seal the chamber, it's lighter, and also much easier and prolongs the life of the extractor.

- Q: How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. First, the coils are cleaned to remove any dirt, grease, or other contaminants. Then, they are dipped into a bath of molten zinc or coated with a protective layer using various methods such as electroplating or hot-dip coating. After the coating process, the coils may undergo further treatments like drying, cooling, and leveling to ensure uniformity and quality.

- Q: I'm putting a bathroom in my basement. I'm an Ironworker btw. I wanted to go with steel studs due to the fact that they are light, and I won't have a big mess. I live in the Chicago area and they should be easy to find. Here is my question. Are they not being used anymore? I ordered 100 studs from Lowe's but they didn't have track. The delivery guy was a retired Carpenter and he told me that I got all the studs they had, they no longer stock steel studs, and they don't have track. Am I missing something? Menards didn't have track either.

- Ask a Carpenter friend where you can buy metal studs. There should be a large drywall supplier somewhere close to your area - they usually also stock metal studs and ceiling grid that sort of all goes together for contractors. You will have a choice of 20 or 25 gauge studs track. 25 gauge is pretty flimsy so I suggest using 20 gauge. Get a small box of tek screws to attach studs to track. Also get some self drilling drywall screws 1+5/8 for 5/8 thick gyp bd. or 1+1/4 for 1/2 gyp bd. I would also buy MR drywall (moisture resistant) for any work in a basement. Another tip : Buy some 1x4 composite trim boards to use for your bottom plate. Clean the slab good where you plates will go, then use some Liquid Nails hd and glue your plates down to the slab. That way you won't be drilling holes in the slab that could allow water to seep up through them. The composite trim will not wick moisture and it will keep your metal studs up off the floor should you ever have a water problem in the bathroom. Keep your drywall up off the floor about 1/2 by laying a scrap pc. of drywall against the plate before you hang the board. Allow enough room to line the perimeter of your door frame with 2x 4 vs. metal stud. It makes it easier installing the door and trim.

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a series of processes that involve the transformation of raw materials into the final product. The manufacturing process begins with the extraction of iron ore, which is then smelted in a blast furnace to produce pig iron. The pig iron is further refined in a basic oxygen furnace to remove impurities and adjust the carbon content. Once the molten steel is obtained, it is continuously cast into large slabs or billets. These slabs are then rolled into thinner sheets or strips through a process called hot rolling. This involves passing the steel through a series of high-pressure rollers, which reduce the thickness and shape the material to the desired dimensions. During this process, the steel is also treated to improve its mechanical properties, such as strength and hardness. After hot rolling, the steel is pickled and cleaned to remove any scale or impurities on the surface. It is then cold rolled to further reduce the thickness and improve the surface finish. Cold rolling involves passing the steel through a set of rollers at room temperature, which increases its strength and dimensional accuracy. To form steel coils, the cold-rolled steel is typically wound tightly into a large coil shape. This is achieved by feeding the steel strip through a series of rollers that gradually wind it into a spiral. The coils are then typically annealed to relieve internal stresses and improve the material's formability. Finally, the steel coils are coated or treated, depending on their intended use. This can involve applying a protective coating, such as zinc or paint, to enhance corrosion resistance or providing a specific surface treatment for improved adhesion in subsequent processes. Overall, the manufacturing of steel coils is a complex process that involves several stages, including smelting, casting, hot rolling, cold rolling, coiling, and surface treatment. Each step contributes to the final product's quality and properties, ensuring that steel coils meet the required specifications for various industrial applications.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

- Q: which cost more: ALLOY, GUNMENTAL OR STAINLESS STEEL. GIVE ME AN IDEA OF THE COST OF EACH.

- Titanium alloy is. Its the hardest metal in the world and takes about 6 months to produce. I sell titanium juliets for 350.

Send your message to us

HOT-DIPPED GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords