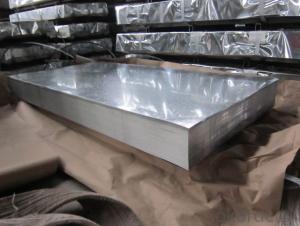

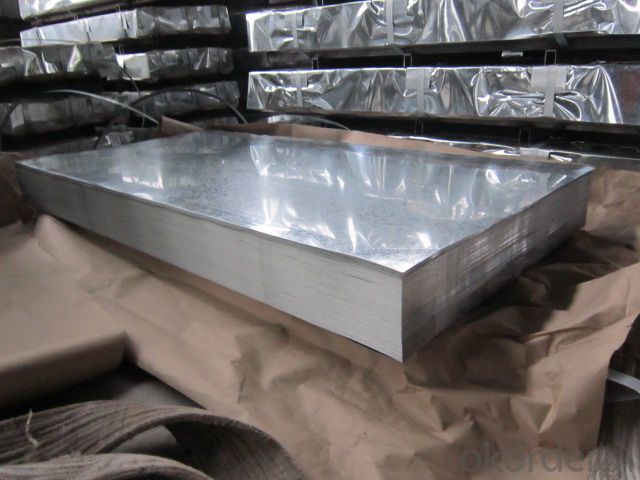

Hot dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dipped Galvanized Steel Sheet in Sheet

Description:

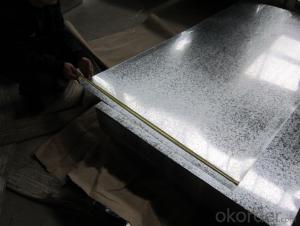

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

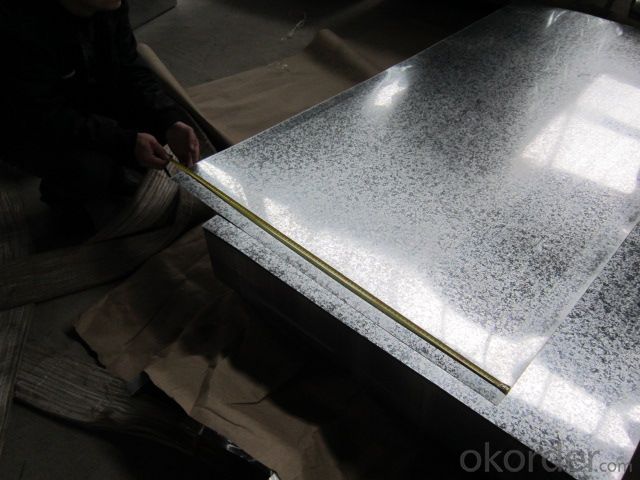

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

- Q: Can steel coils be coated with QR codes?

- Yes, steel coils can be coated with QR codes. QR codes can be printed or engraved onto the surface of the steel coils, allowing for easy scanning and identification of the coils.

- Q: Which one has more electrical resistivity? Wood or steel? And why?I know that the resistivity depends on the material of the conductor, but i want a perfect explaination please.Thnx in advance :)

- Steel Resistivity

- Q: What are the advantages of using steel coils over other materials?

- There are several advantages of using steel coils over other materials. Firstly, steel is highly durable and has a long lifespan, making it ideal for various applications. Secondly, steel coils have excellent strength and can withstand heavy loads and extreme weather conditions. Thirdly, steel is recyclable and environmentally friendly, ensuring sustainability. Additionally, steel coils provide superior corrosion resistance, reducing maintenance costs. Lastly, steel offers versatility in terms of customization, allowing for various shapes, sizes, and thicknesses to meet specific requirements.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: How are steel coils inspected for thickness using ultrasonic testing?

- Steel coils are inspected for thickness using ultrasonic testing by first preparing the surface of the coil and applying a couplant gel. Then, an ultrasonic transducer is placed on the surface and emits high-frequency sound waves into the coil. These sound waves travel through the material and are reflected back when encountering a change in thickness. The transducer receives these echoes and measures the time it takes for them to return. By analyzing the time delay, the thickness of the steel coil can be accurately determined.

- Q: What is the maximum stacking height for steel coils?

- The maximum stacking height for steel coils depends on various factors such as the size and weight of the coils, as well as the strength and stability of the storage facility. Generally, it is recommended to stack steel coils up to a height of 3 to 5 coils, ensuring proper weight distribution and stability to prevent damage or accidents.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: Why can't you use a lead shot only choke with steel shot or a steel shot only choke with lead shot? I have used a lead only choke with steel shot and my shotgun shot fine and there was no damage to the choke.

- To add to this, Screw-In tubes in older guns can make removal a challenge. I destroyed a FULL lead tube removing it for a friend from his NOVA.

- Q: I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- It will be very effective if you remove the oil by appling protective polymer spin coating to the edge, top and underside of the wafer, which makes those surfaces impervious to most chemical etchants. To learn more about the spin coating theory you may check out the following source.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- No. Not quite. The term 'Hardened steel' is often used to refer to 'Heat treated steel'. There are two separate steps in heat treatment. First the red hot steel is 'quenched' (rapidly cooled). This yields maximum hardness ,but the steel may be too brittle for the intended purpose. The next stage, 'tempering' is heating to a limited temperature, and slow cooling. This reduces the hardness somewhat, depending on the re-heat temperature, but restores some of the toughness lost in the first stage.

Send your message to us

Hot dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords